Filter device

A filter and filter surface technology, applied in chemical instruments and methods, household heating, heating methods, etc., can solve the problems of small filter surface inclination, unreliable grease, dripping on the stove, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

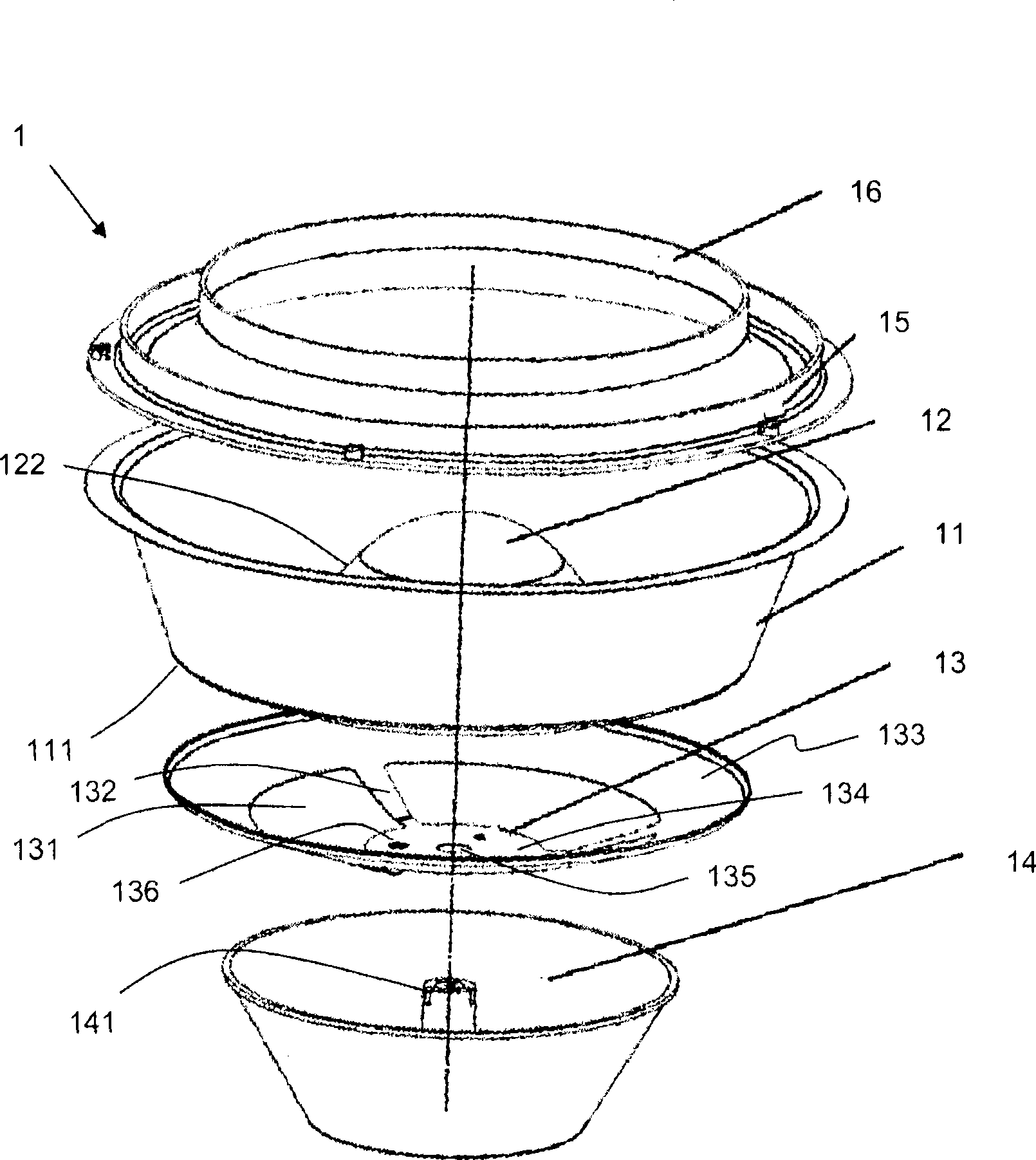

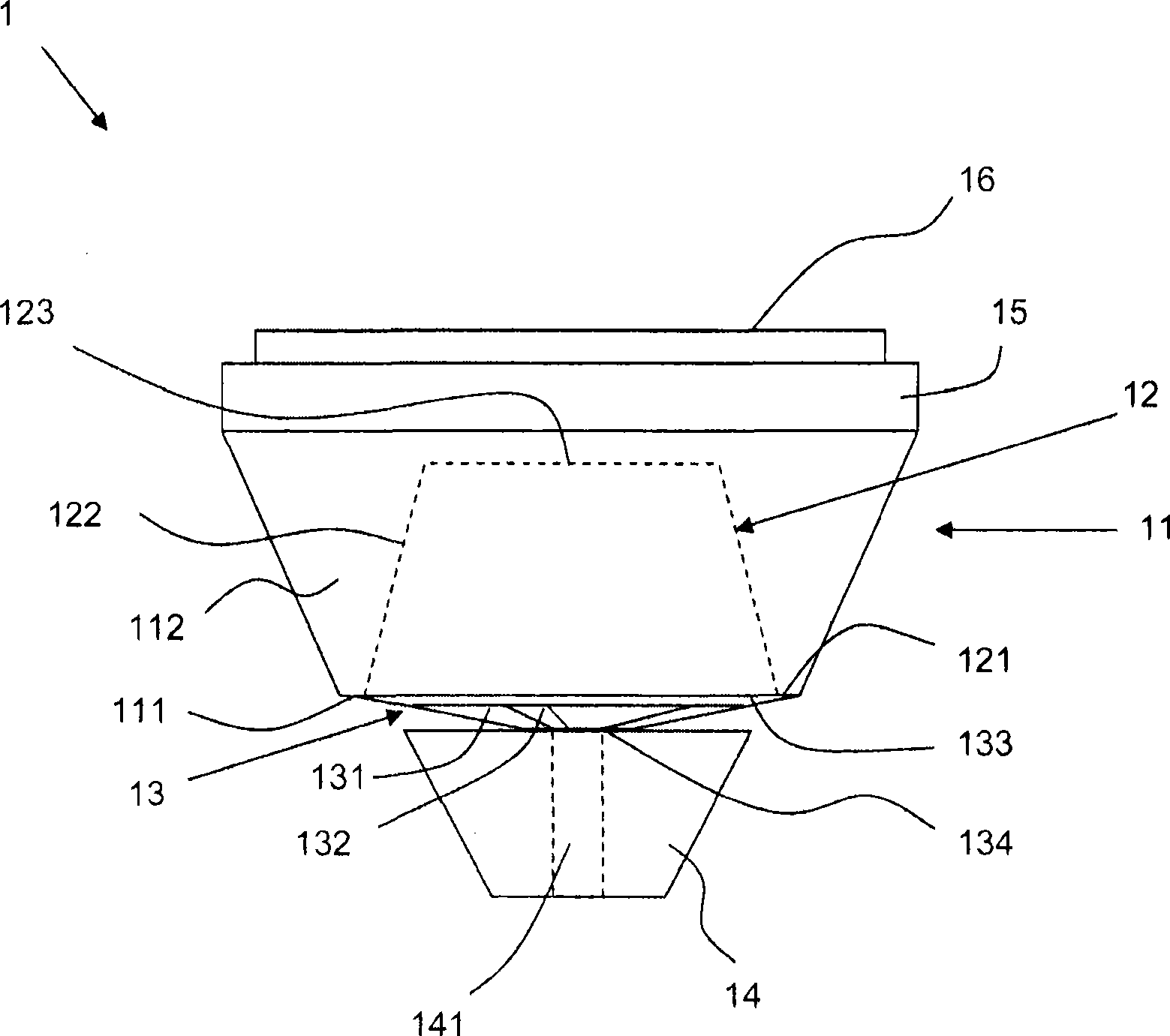

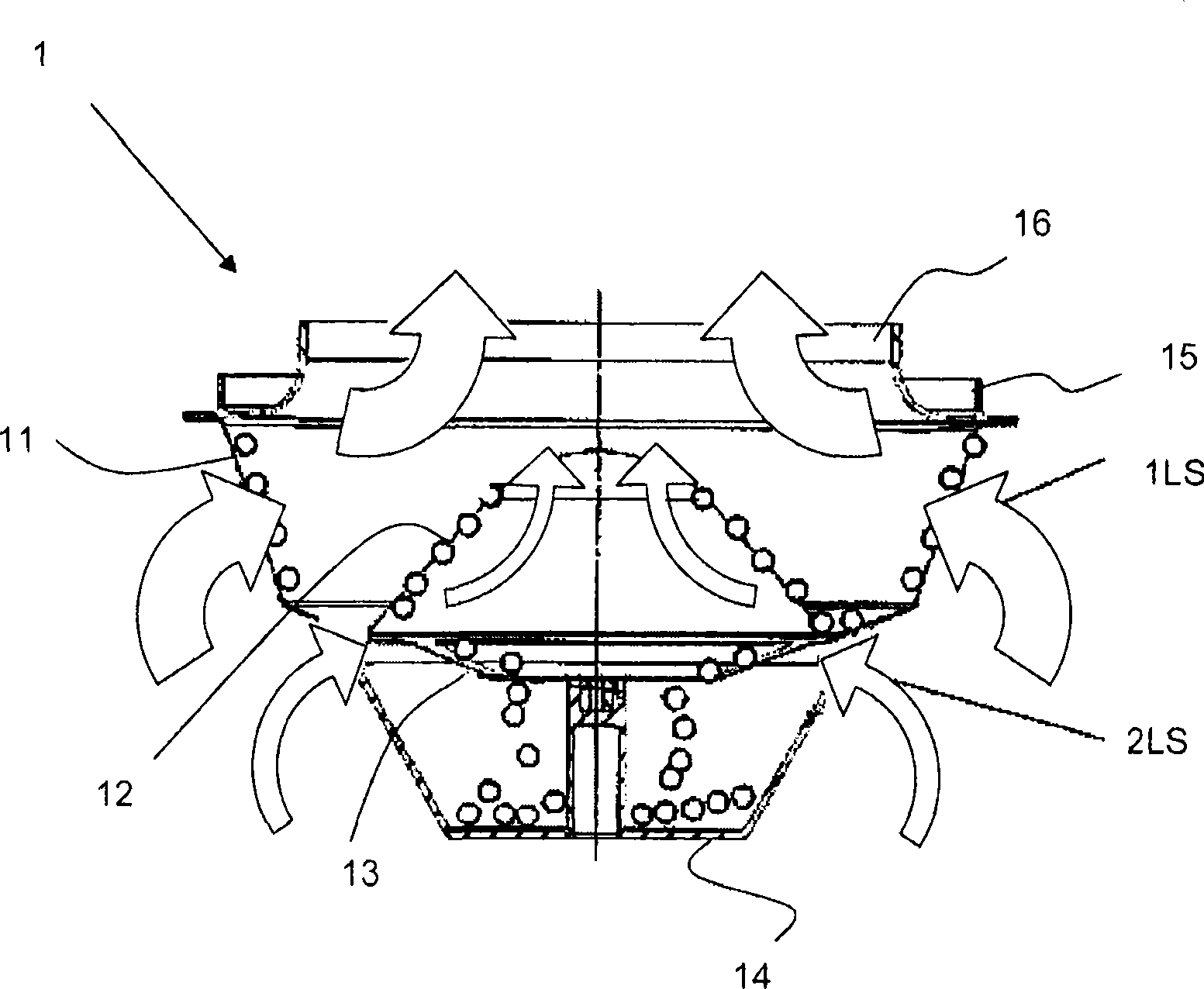

[0035] figure 1 An exploded schematic view of an embodiment of the filter device 1 according to the invention is shown. The filter device 1 comprises an outer first filter element 11 , an inner second filter element 12 and a collection container 14 arranged below the filter elements 11 , 12 . Between the collection container 14 and the filter elements 11 , 12 a base plate 13 is arranged as a discharge device. A connecting ring 15 is arranged above the first filter element 11 . The filter element 11 can be connected to a smoke extraction hood (not shown) via this connecting ring. An inflow nozzle 16 is arranged in the connection ring 15 . Through these nozzles air can flow from the filter device 1 into the interior of the smoke extraction hood. Air is sucked through the filter device 1 into the smoke extraction hood by a fan in the smoke extraction hood.

[0036] In the embodiment shown, the filter surface 112 of the first filter element 11 has the shape of a truncated con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com