Tappet rod for operating switch element

A technology for manipulating switches and switching elements, applied in the direction of electric switches, electrical components, contact operating parts, etc., can solve problems such as damage, damage to sealing devices, and adverse effects of force conversion operation heads, so as to avoid corrosion and prevent The effect of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

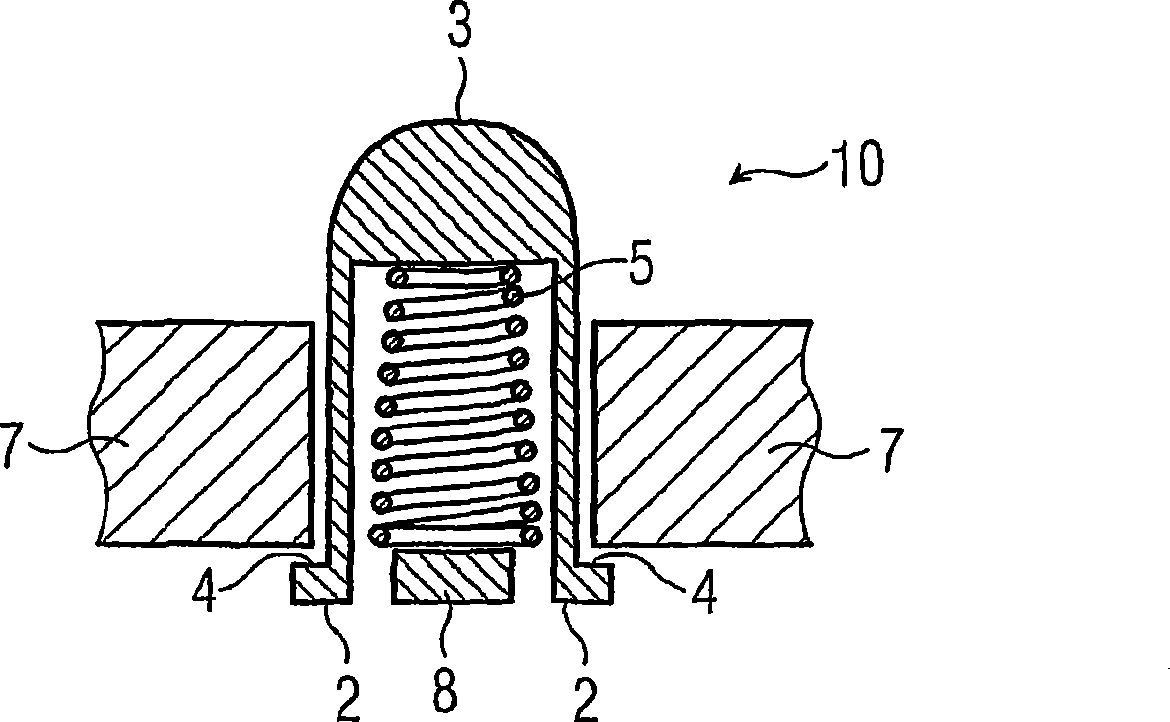

[0028] figure 1 Shown is a cross-sectional view of a first embodiment of a lifter 10 in an installed state. The tappet 10 shown comprises an elastic element 5 embodied as a compression spring, an actuation zone 3 for actuating the tappet 10 by an operating head (not shown), and for actuating the switching unit or the switch unit by the tappet 10. Active surface 2 on which switching element 1 is actuated. The direction of actuation of the tappet 10 is directed from top to bottom. The above-mentioned elastic element 5 abuts both on the blocking device 8 and on the inner side of the above-mentioned tappet 10 . The tappet 10 is in an unactuated starting state (basic position). That is to say, the restoring force action of the spring element 5 is transmitted by the stop 4 to the holder 7 of the housing. When the tappet 10 is manipulated through the manipulation zone 3 , the elastic element 5 is compressed, and the restoring force is transmitted to the manipulation element (not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com