Microstrip filter

A microstrip filter and microstrip line technology, which is applied in the directions of waveguide devices, electrical components, circuits, etc., can solve the problems of inconvenient application and large size of the microstrip filter, and achieve simple structure, small size, good The effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The microstrip filter of the present invention is mainly composed of a metal plate with a cross-shaped capacitive effect connected in parallel and two defective grounding structures with inductive effect connected in series.

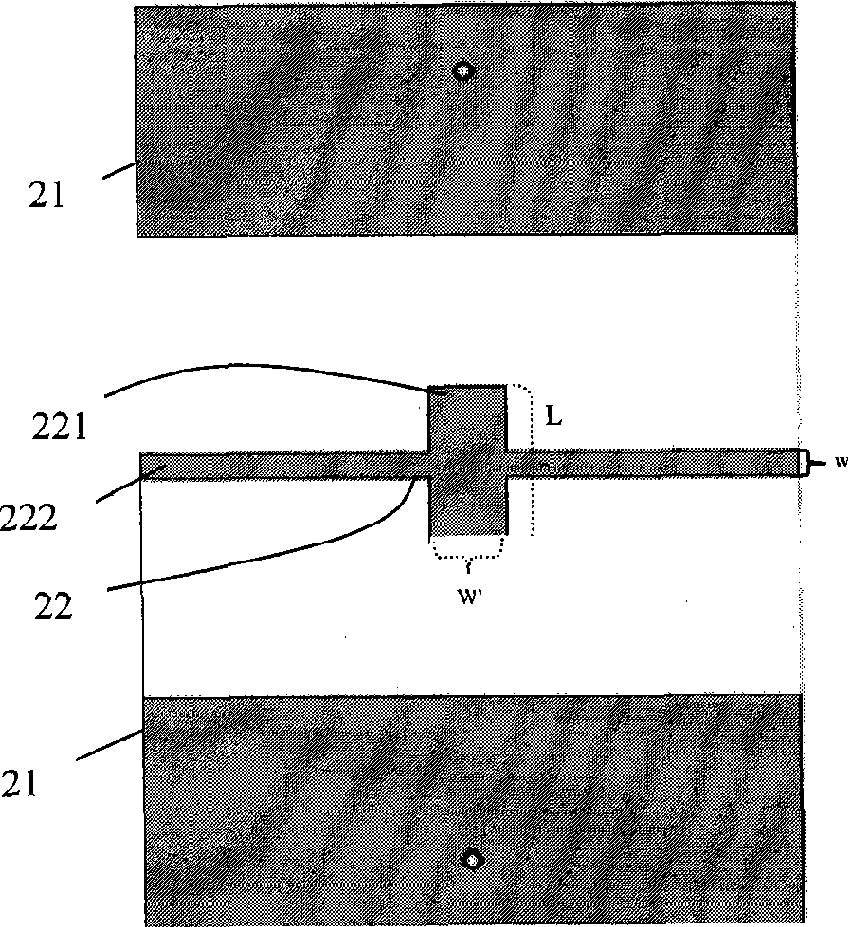

[0016] Figure 2a and Figure 2b They are the top-layer and bottom-layer structure diagrams of the microstrip filter in the best embodiment of the present invention, respectively. image 3 It is the three-dimensional structural diagram of this embodiment. Such as Figure 2a and 2b and image 3 As shown, the top layer of the microstrip filter 1 includes a cross open microstrip line 22 with capacitive effect, and the cross open microstrip line 22 can be made of metal such as copper. The cross open microstrip line 22 includes vertical lines 221 and horizontal lines 222 . The width w of the horizontal line corresponds to the characteristic impedance, where w is 18 mils (1 mil=0.0254 mm), corresponding to a characteristic impedance of 50 ohms, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com