Device and method for measuring light sheet thickness

A thickness measurement and thin plate technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of uneven thickness, thin plate thickness measurement accuracy deviation, large-size thin plate positioning accuracy and low repeat positioning accuracy, and achieve repeated measurement Good precision and guaranteed precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

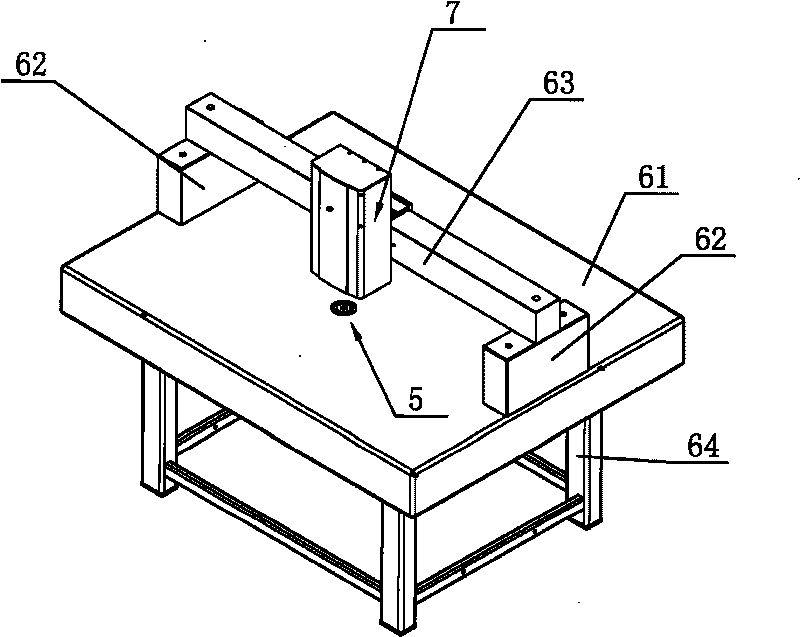

[0026] see figure 1 The thickness measuring device shown includes an angle seat 64, a thickness measuring platform 61 arranged on the angle seat 64, a spacer 62 arranged on the thickness measurement platform 61, a spacer 62 arranged on the spacer 62 The beam 63 on the top, the measuring device 7 set on the beam 63, and the positioning device 5 set on the thickness platform 61.

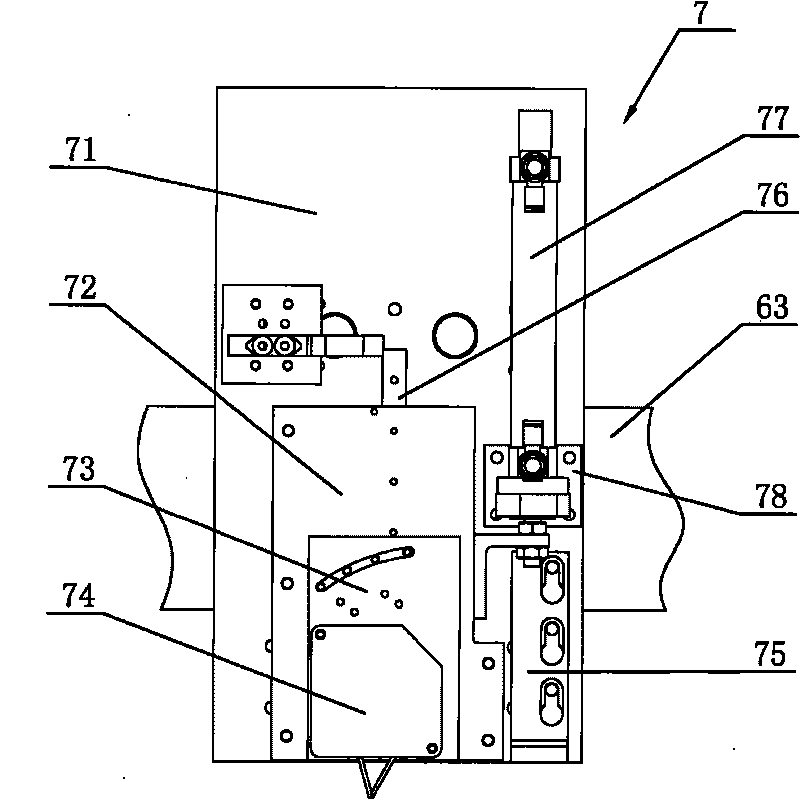

[0027] see figure 2 The measuring device 7 includes a mounting base plate 71 arranged on the beam 63, a guide rail 76 fixed on the mounting base plate 71, a probe installation adapter plate 73 slidably arranged on the guide rail 76, fixed on the The laser probe 74 on the adapter plate 73 is installed on the probe, and the cylinder base 78 is also arranged on the installation substrate 71. The cylinder 77 is fixed on the cylinder base 78, and the piston rod of the cylinder 77 is connected to the The probe installation adapter plate 73 is connected, so that the cylinder 77 can drive the probe installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com