Non-metal Dewar container of high temperature superconduction magnetic suspension experiment vehicle

A high-temperature superconducting and Dewar container technology, applied in pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve problems affecting normal work, heavy workload, high cost, etc., to ensure normal driving and maintenance workload The effect of small, low-cost manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

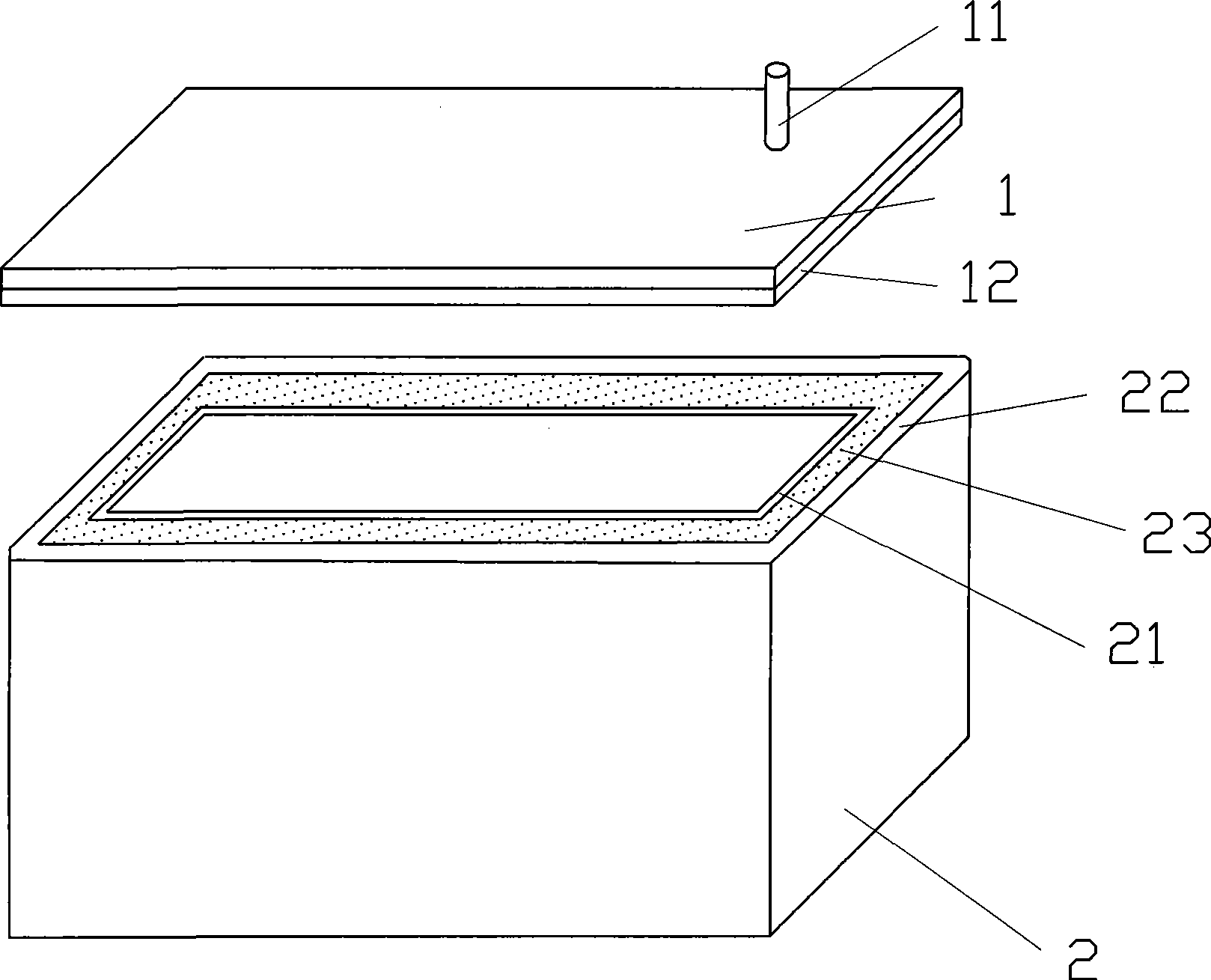

[0018] figure 1 Shown, a kind of specific embodiment of the present invention is: a kind of non-metallic Dewar container for high-temperature superconducting maglev experiment vehicle, and its composition is: be made up of non-metallic upper cover 1 and non-metallic container body 2, upper cover 1 is provided with an air nozzle 11, and the bottom of the upper cover 1 is provided with a sealed heat insulating layer 12; the side wall of the container body 2 is a sandwich structure composed of inner and outer layers 21, 22, and the inner and outer layers are filled with heat insulating materials twenty three. The thickness of the bottom of the container body 2 is 3-6 mm.

[0019] The heat insulating material 23 filled between the inner and outer layers 21 and 22 of this example is composed of heat insulating paper and plastic film alternately stacked, that is, a layer of insulating paper is stacked with a layer of plastic film, and stacked layer by layer, so that any two layers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com