Exterior wall exterior heat preservation system for spray coating polyurethane rigid foam

A technology of external thermal insulation and spraying polyurethane, applied in thermal insulation, building thermal insulation materials, building components, etc., can solve the problems of shedding, cracking of the surface layer, swelling, etc., to prevent hollowing of the wall surface, quick construction, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

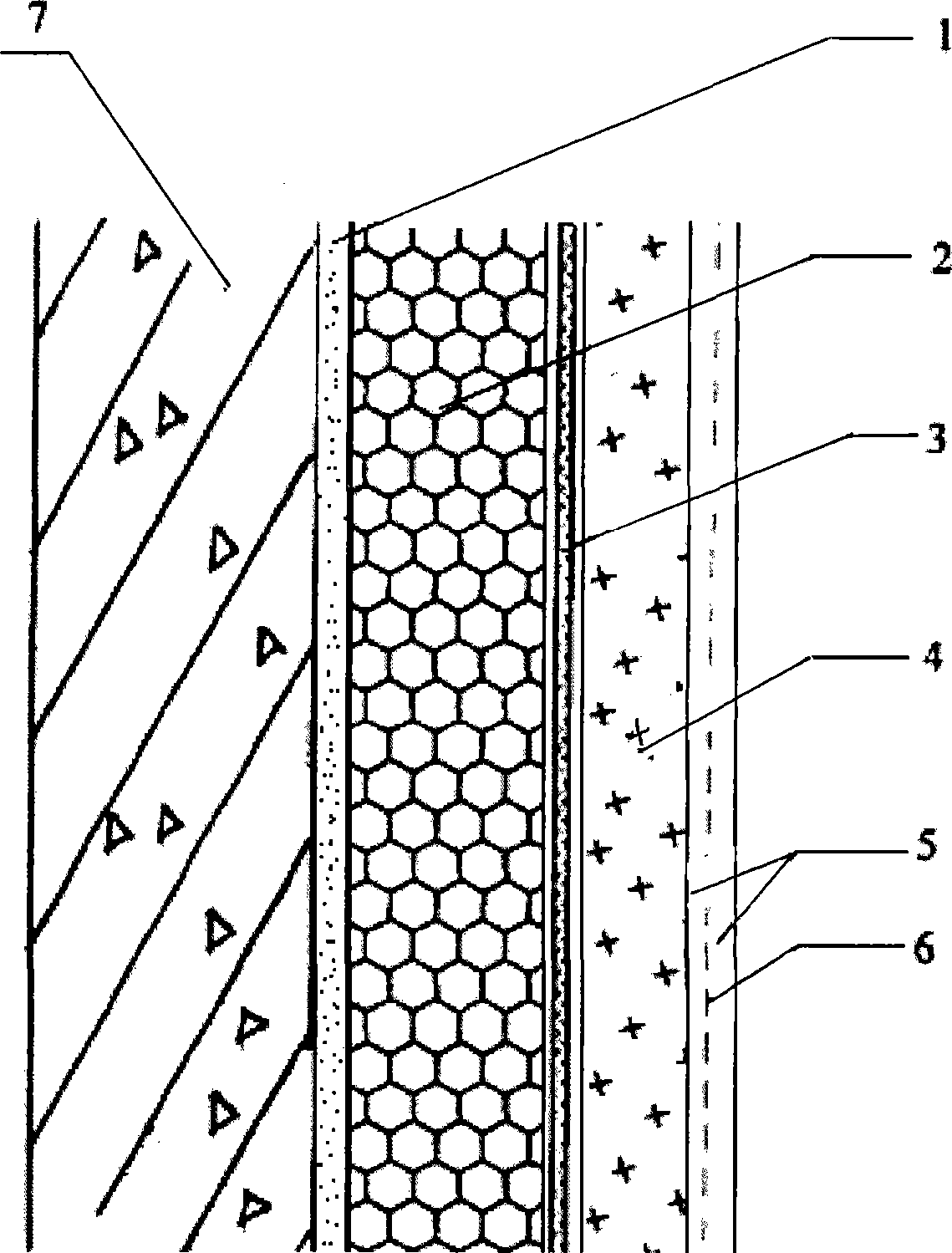

[0026] Such as figure 1 As shown, it is a schematic structural diagram of spraying polyurethane rigid foam external wall external thermal insulation system. The system is composed of base spraying polyurethane special moisture-proof primer 1, polyurethane rigid foam 2, interface mortar 3, leveling layer 4, and alkali-resistant mesh cloth 5. Composition of plastering mortar 6 and base wall 7.

[0027] Moisture-proof primer 1, polyurethane hard foam 2, interface mortar 3, leveling layer 4, and plastering mortar 6 are all products for sale by the applicant unit.

[0028] Polyurethane is directly sprayed on the base wall surface 7 coated with moisture-proof primer 1, and forms a cavity-free bond with the base wall surface through its own bonding effect, and a leveling layer 4 is provided outside the polyurethane hard foam 2. An interface mortar 3 is provided between the leveling layer 4 and the sprayed polyurethane hard foam, an alkali-resistant mesh cloth 5 is arranged outside t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com