Hydraulic transmission type anti-explosion diesel engine steel wheel standard rail diesel locomotive

An explosion-proof diesel engine and hydraulic transmission technology, applied in the field of hydraulic torque converters, can solve the problems of complicated maintenance, small traction tonnage, and inability to satisfy users.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

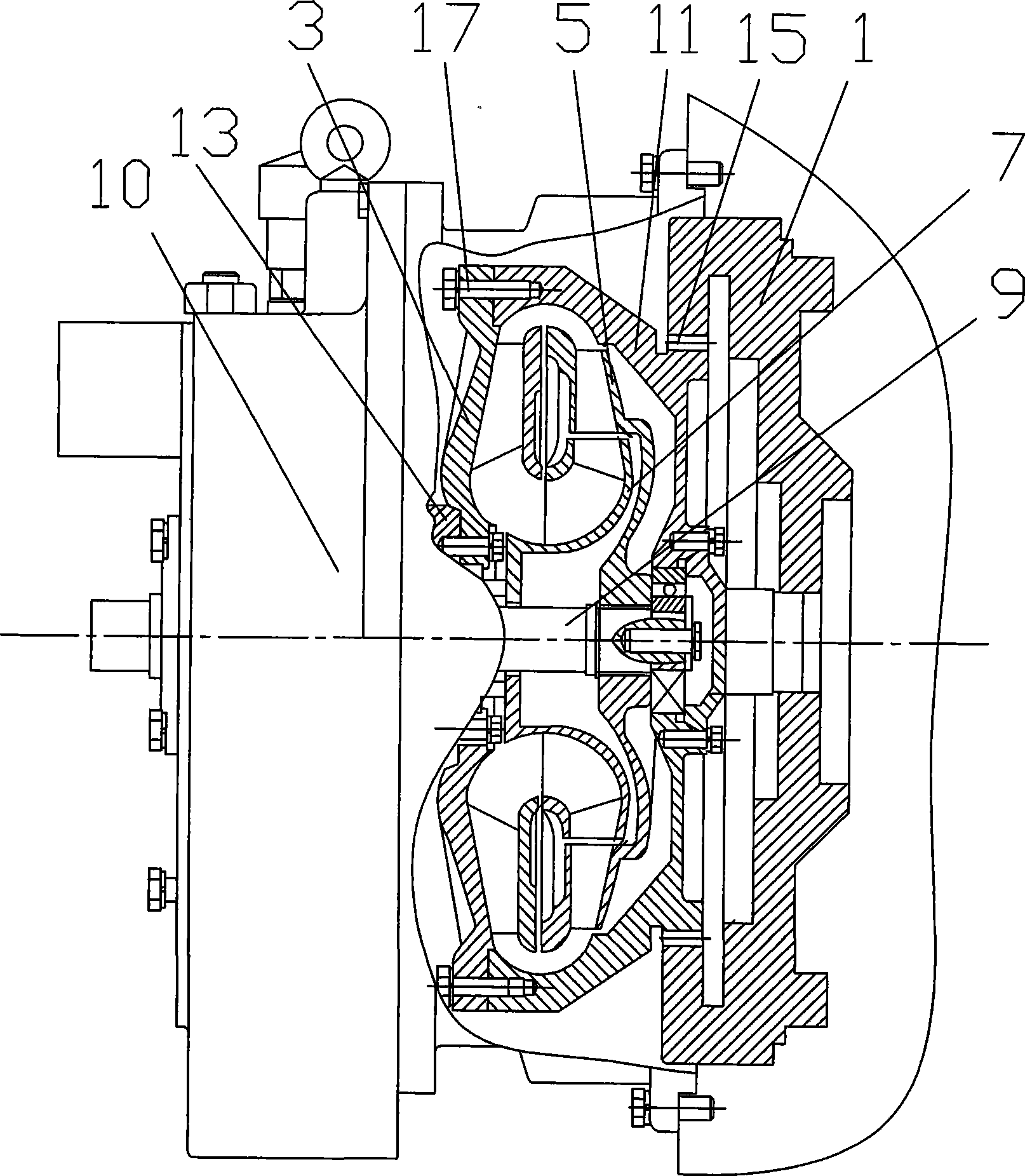

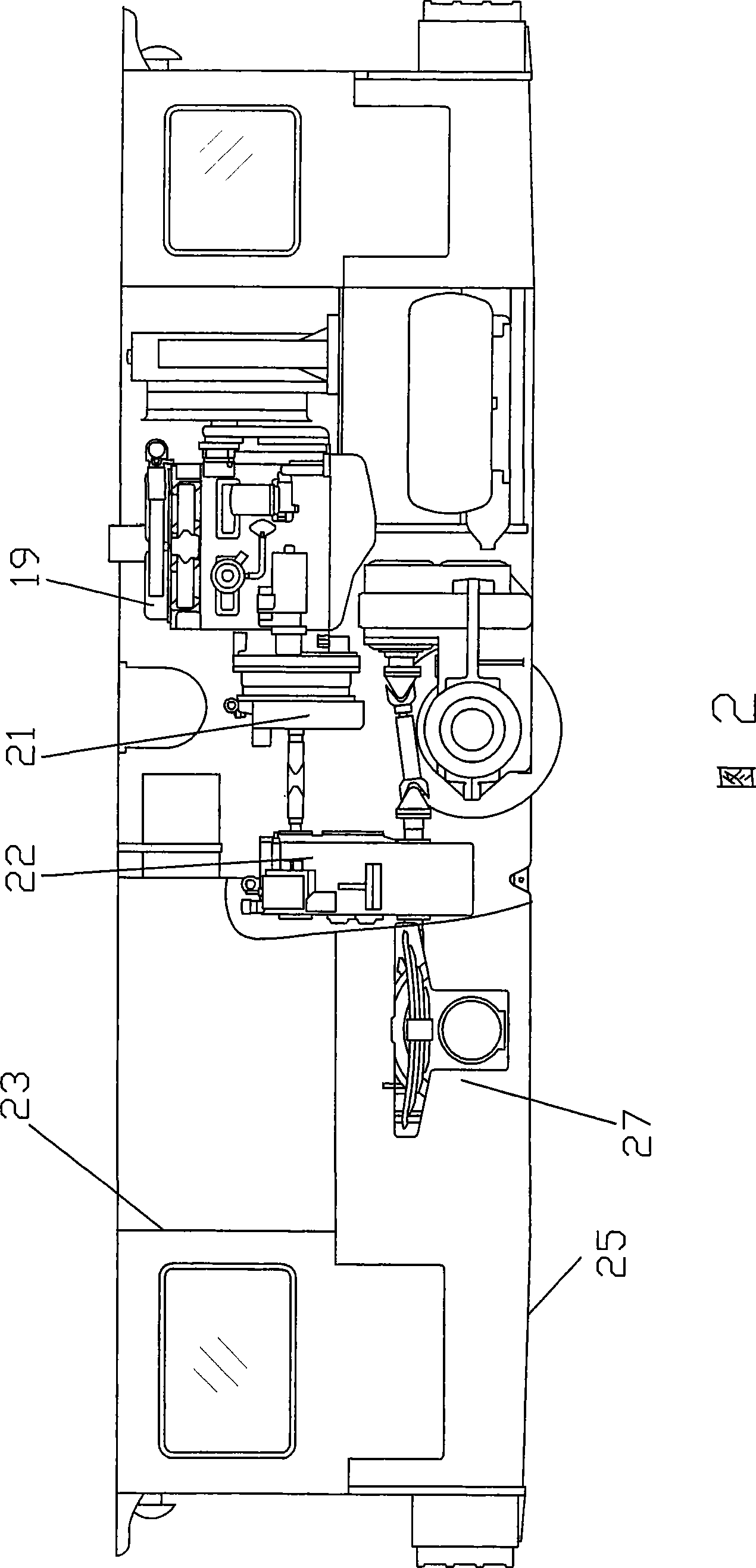

[0013] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0014] Such as figure 1 The hydraulic transmission type explosion-proof diesel engine steel wheel general-rail diesel locomotive shown in -2 is a 0-2-0 axle shunting type locomotive, and its structure includes explosion-proof diesel engine 19, hydraulic torque converter 21, reversing and shifting Box 22, car body 23, vehicle frame 25, running part 27 and auxiliary device 29.

[0015] Explosion-proof diesel engine 19: The explosion-proof diesel engine 19 has an output disk 1, which is the power unit of the locomotive, and its function is to convert the chemical energy of the fuel into mechanical work.

[0016] Hydraulic tor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com