Automatic power-passing phase-splitting apparatus of AC drive electric locomotive

A technology for electric locomotives and over-power phase separation, which is applied in power lines, vehicle components, transportation and packaging, etc., and can solve the problems of transformer surge current, large locomotive traction loss, and inability to pass the phase separation zone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

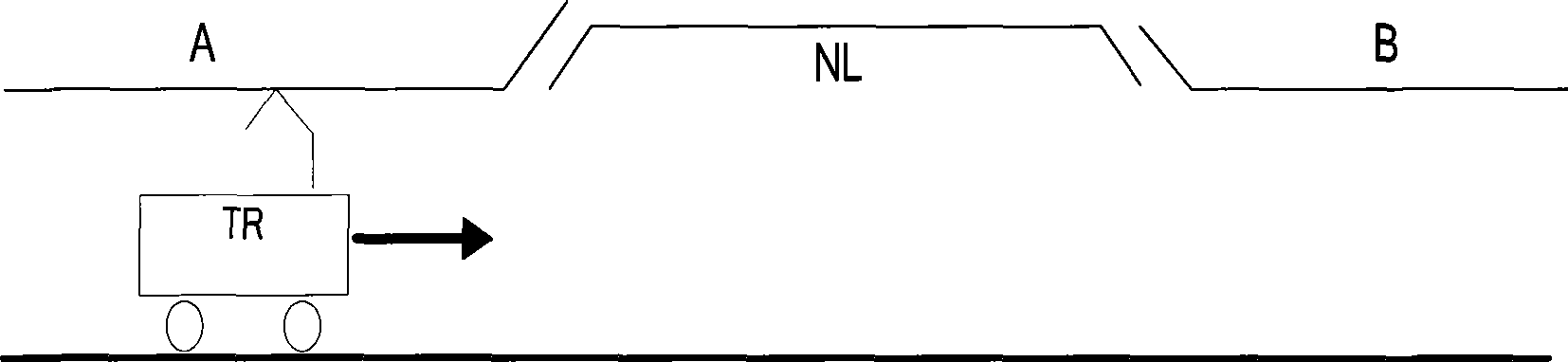

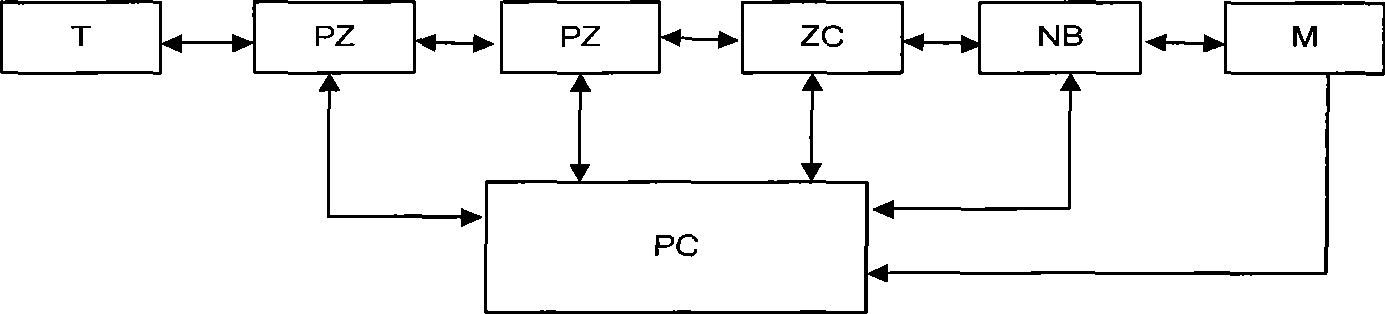

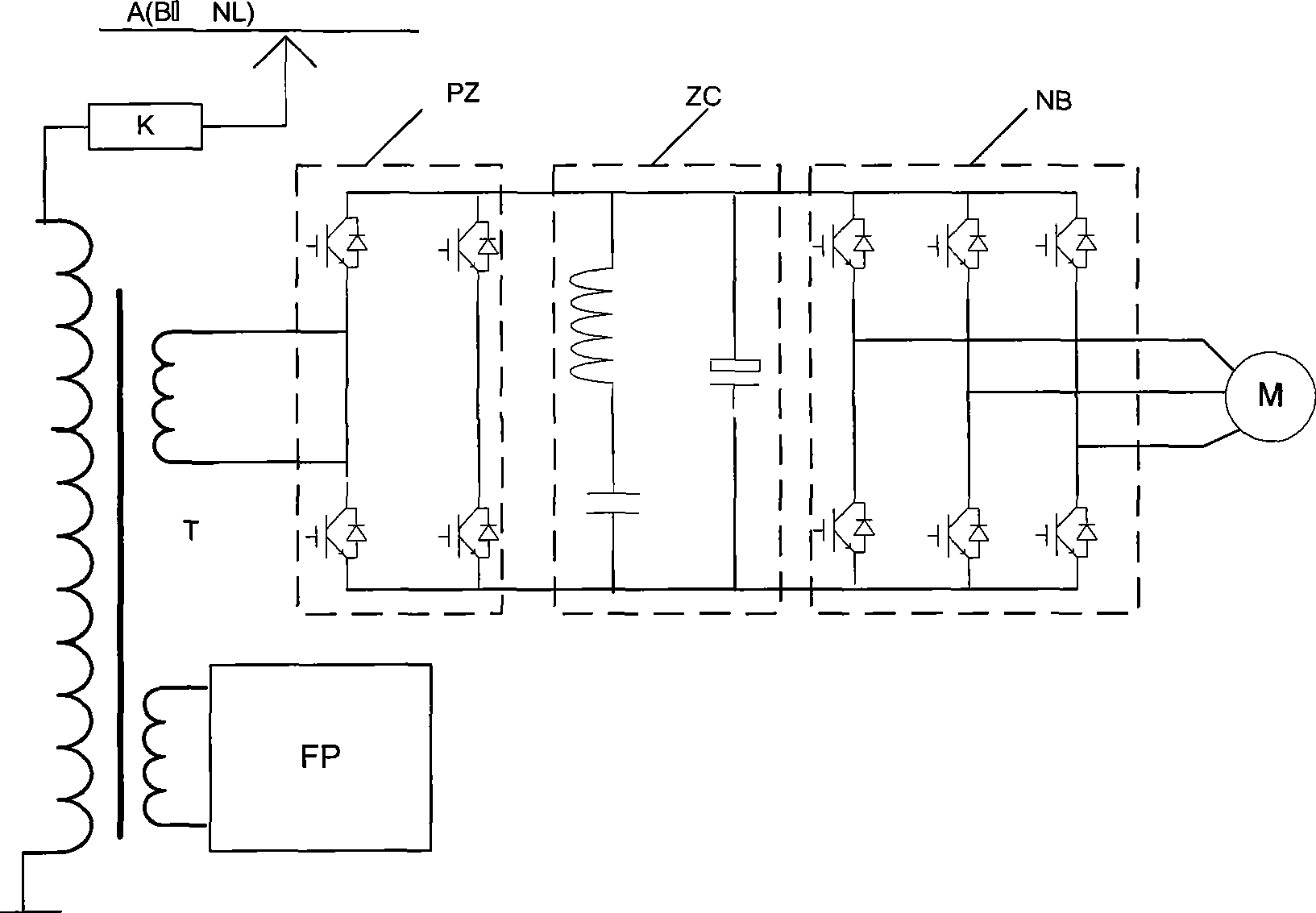

[0028] Figure 1-3 As shown, a specific embodiment of the present invention is: a method for automatic over-current phase separation of an AC-DC electric locomotive, and its method is as follows:

[0029] A. During normal driving, the traction control system controls the traction motor M to be in the traction working state. After the traction voltage on the power supply arm A is stepped down by the traction transformer T, it is converted into a stable DC voltage by the pulse rectifier PZ and supplied by the filter circuit ZC. The traction inverter is finally converted by the traction inverter NB into three-phase alternating current, which is supplied to the traction motor M to drive the locomotive TR forward.

[0030] B. Before the locomotive enters the neutral section, the traction control system PC controls the traction motor M to work in the regenerative braking state, so that the intermediate DC voltage remains stable, and at the same time controls the pulse rectifier PZ t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com