Stitch pulsation welding device

A pulse welding and pin technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of large indicating workload and difficult combination of welding current and welding time, so as to reduce indicating workload and shorten production takt time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, embodiments of the invention will be described based on examples with reference to the drawings.

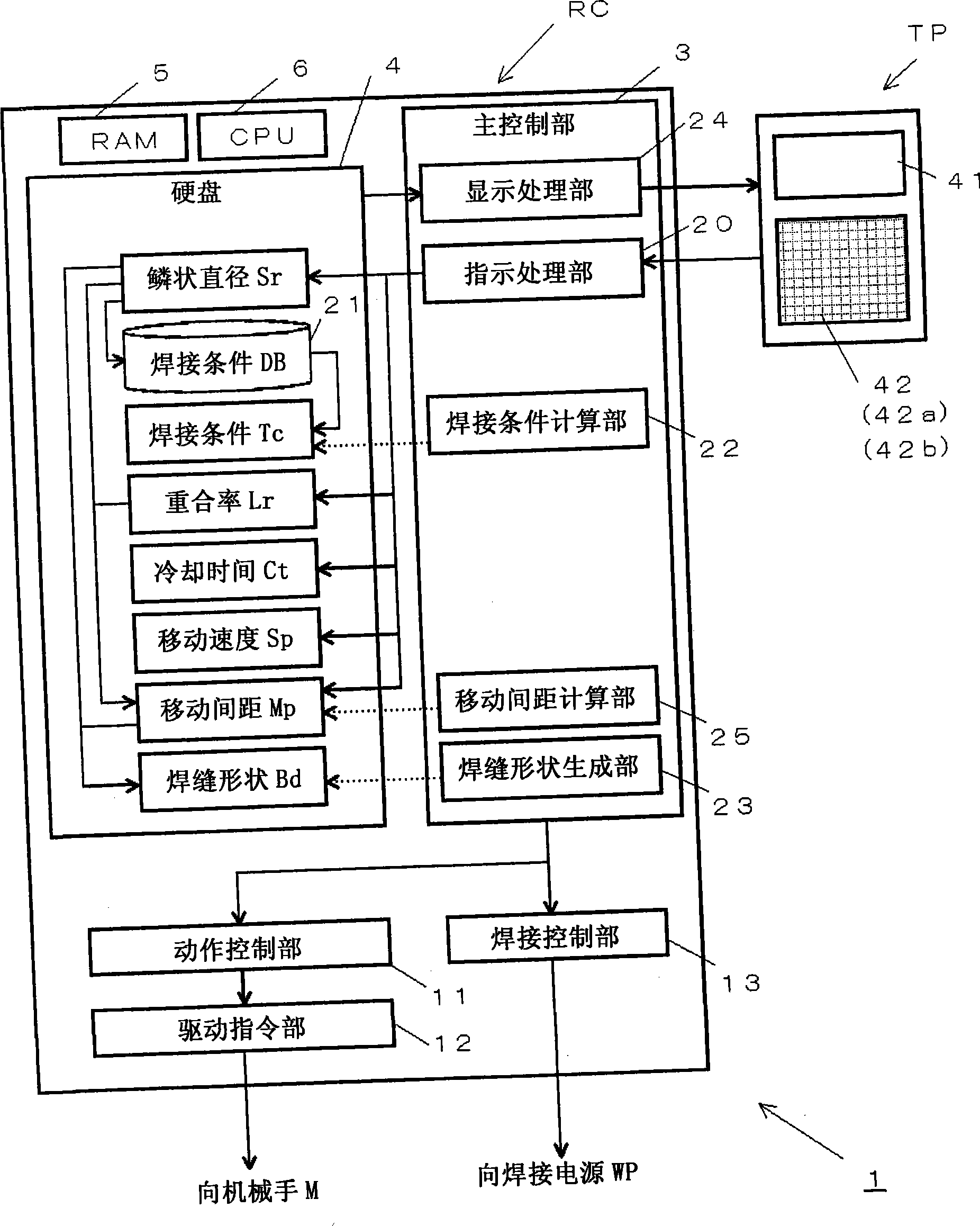

[0041] figure 1 It is a block diagram of the stitch pulse welding device 1 of the present invention. In this figure, with the prior art Figure 5 The difference lies in the robot controller RC and the indicator panel TP as operating unit. In addition, not shown and omitted Figure 4 The manipulator M, the welding power source WP, the welding wire reel 56, the gas tank 58, etc. described in Hereinafter, the robot controller RC and the indicator panel TP constituting the main parts of the present invention will be described.

[0042] The robot control device RC is a device for controlling the welding operation of the manipulator M, and includes: a main control unit 3 serving as the center; performing calculations on the trajectory of the manipulator M, etc., and outputting the calculation results as drive signals to the drive command unit 12 A motion contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com