Filter material of cigarette filter stick and cigarette filter stick

A filter rod and filter element technology, applied in e-liquid filter, tobacco, application and other directions, can solve problems such as no technical reports on cigarette filter rods, so as to ensure no loss of natural cigarette aroma, increase smoke concentration, and appearance is white and beautiful Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 expanded shredded tobacco particles

[0030] The granules are expanded shredded tobacco granules with a particle size of 30-100 meshes, the flavoring agent is added according to the weight ratio of flavoring agent:expanded shredded tobacco granules at 0.005-0.015:1, and the moisture content of the granules is controlled to be 8-10%. The expanded shredded tobacco granules are shredded tobacco produced when the dry ice method is used to prepare the expanded shredded tobacco, which can be directly sieved for selection, and the expanded shredded tobacco granules with too large particle size can be ground and sieved for use.

[0031] The weight ratio of flavoring agent:expanded shredded tobacco particles is preferably 0.01:1. The flavor enhancer can use tobacco shred flavor enhancer commonly used in the tobacco production industry.

[0032] The moisture content of the granules is preferably 10%.

[0033] To collect the expanded shredded toba...

Embodiment 2

[0037] Crush the expanded shredded tobacco and pass through a 30-100 mesh sieve. According to the process method in the prior art, the expanded shredded tobacco particles and the plasticizer are uniformly mixed with the opened fiber acetate base material respectively. The plasticizer is glyceryl triacetate, and the added ratio is 6-8% of the total weight of the filter rod filter material; the expanded shredded tobacco is added in a ratio of 0.5 mg per millimeter long filter rod.

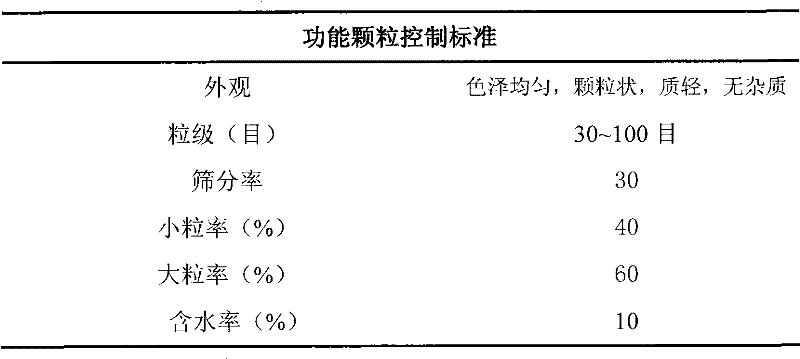

[0038] Table 1 Control Standards of Expanded Shredded Tobacco Particles

[0039]

Embodiment 3

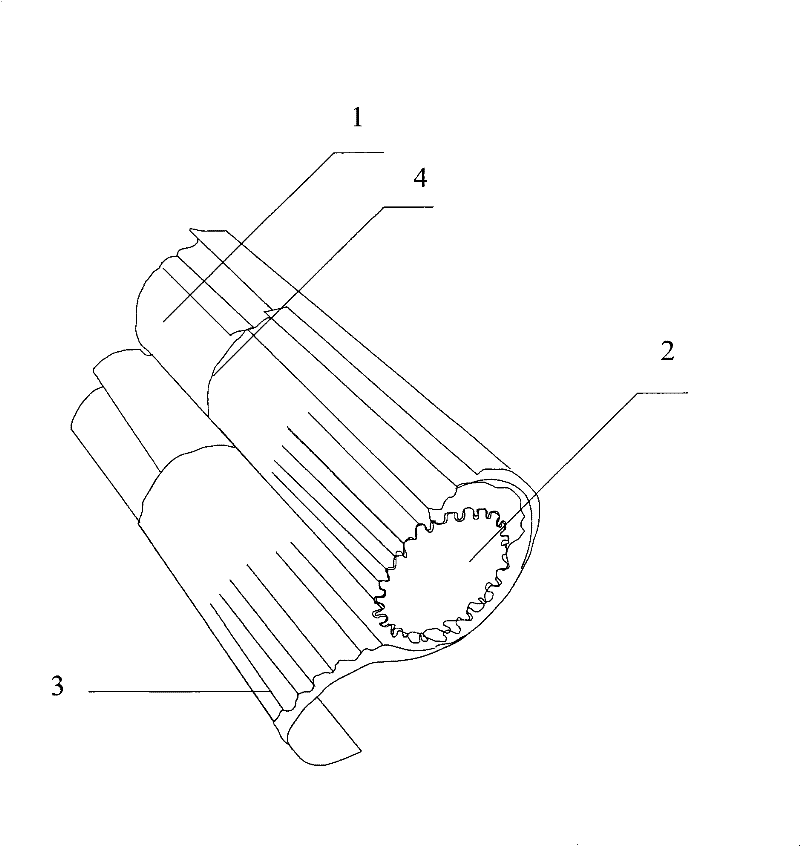

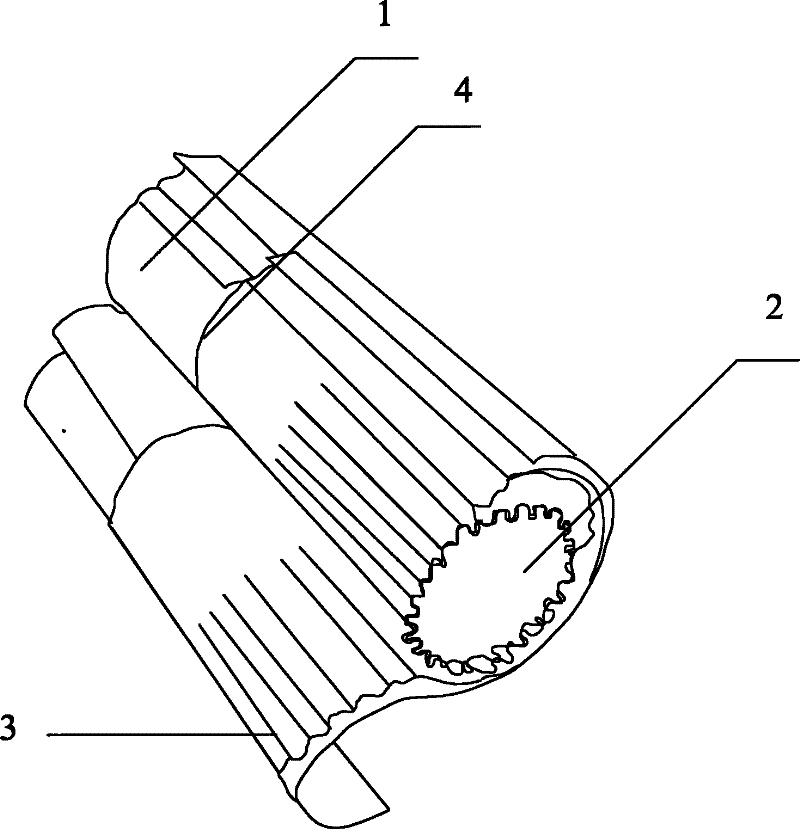

[0040] Application of Example 3 Particles in Cigarette Filter Sticks

[0041] According to the process method in the prior art, the expanded shredded tobacco and the plasticizer are uniformly mixed with the opened fiber acetate base material respectively. The plasticizer is glyceryl triacetate, and the added ratio is 6-8% of the total weight of the filter rod filter material; the expanded shredded tobacco is added in a ratio of 0.5 mg per millimeter long filter rod. Plasticizer control standards refer to existing routines, and Table 1 gives a reference:

[0042] Table 1 Plasticizer Control Standards

[0043]

[0044]

[0045] Table 2 Control Standards of Expanded Shredded Tobacco Particles

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com