Auxiliary bearing saddle assembly for spherical cap of pendulum goods train

A technology for railway freight cars and bearing saddles, which is applied in the direction of the device for lateral relative movement between the underframe and the bogie, and can solve the problem of ensuring the swing function of the side frame of the bogie of the tilting train, reducing the life of the bearing saddle and bearings, and wire transmission. It can reduce the probability of jamming, long fatigue life, and evenly loaded bearings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

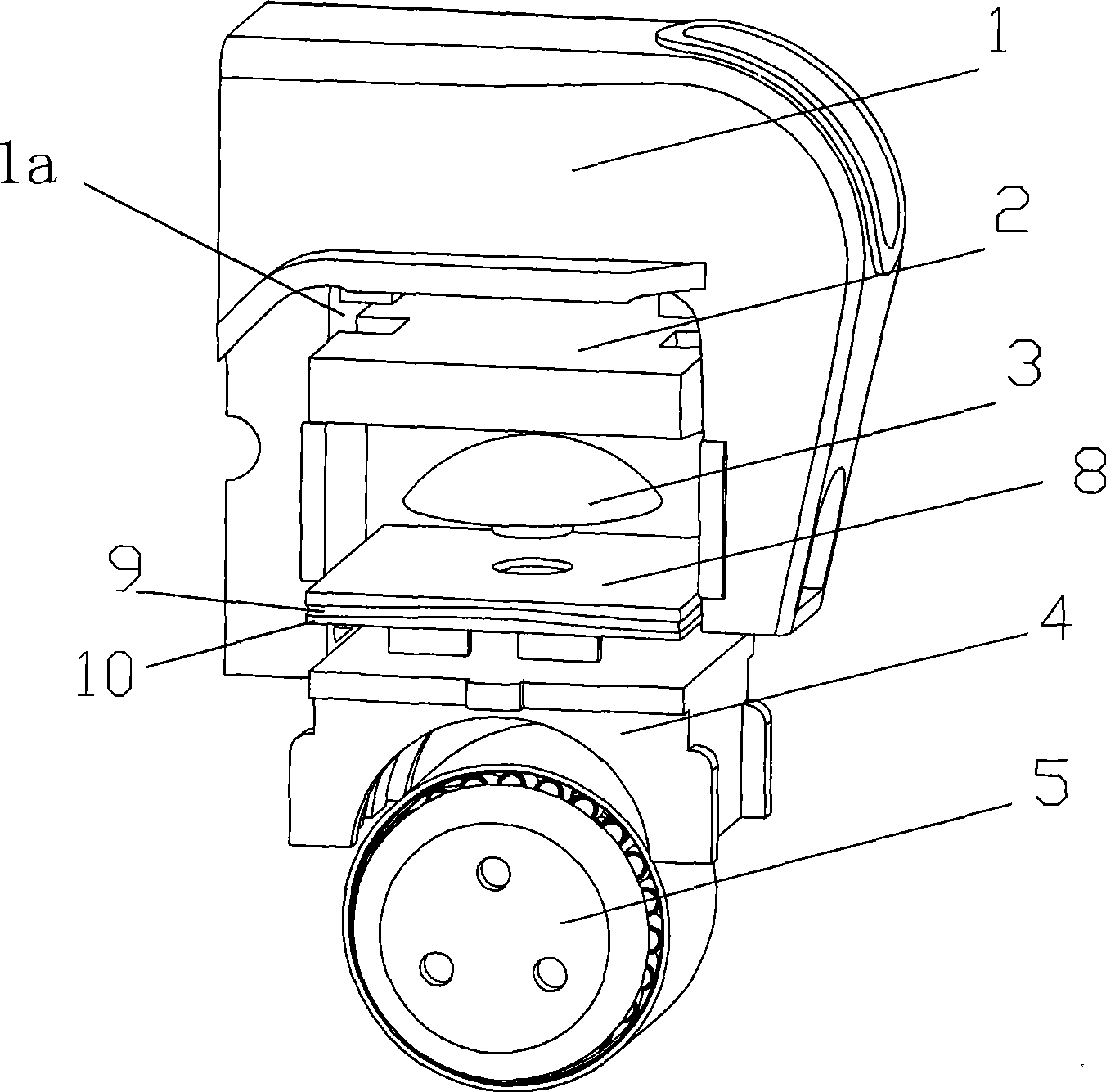

[0026] figure 1 It is shown that the first specific embodiment of the present invention is: a spherical crown auxiliary saddle assembly for a pendulum railway freight car, which includes the swing seat 2 in the guide basket 1a of the side frame 1 and the load saddle below the swing seat 2 4. The lower part of the bearing saddle 4 is in contact with the outer ring of the bearing 5 . Both ends of the upper surface of the rocking seat 2 are inlaid on both sides of the upper part of the guide basket 1a of the side frame 1, the lower surface of the rocking seat 2 is a concave spherical surface, and the concave spherical surface is matched with the convex spherical crown 3, and the lower part of the convex spherical crown 3 is in contact with the bearing. The saddle 4 is connected.

[0027] figure 1 and Figure 5a, Figure 5b, Figure 5c It shows that the working process and mechanical principle of this example are: the rocking seat 2 transmits the force from the side frame 1 to ...

Embodiment 2

[0032] image 3 It shows that the structure of this example is basically the same as that of Example 1, the only difference is that the lower part of the convex spherical crown 3 is connected to the saddle 4 in a specific way: a layer of elastic material is sandwiched between the upper and lower liners 8 and 10 9. The elastic material 9 can generally be rubber or elastic plastic. The lower part of the convex spherical crown 3 and the upper liner 8 are matched by a circular inlay pair with fretting gaps. Generally, a circular protrusion and a concave connection pair can be used to cooperate, which can make it more convenient and simple to install. The inlaid lower liner 10 is inlaid and fastened or clamped on the upper part of the bearing saddle 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com