Liquid milk product added with levorotation carnitine and producing method thereof

A dairy and liquid technology, applied in the field of dairy product processing, can solve the problems of lack, non-recommendation, damage to physical health, etc., and achieve the effects of good physiological function, weight control, and convenient consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

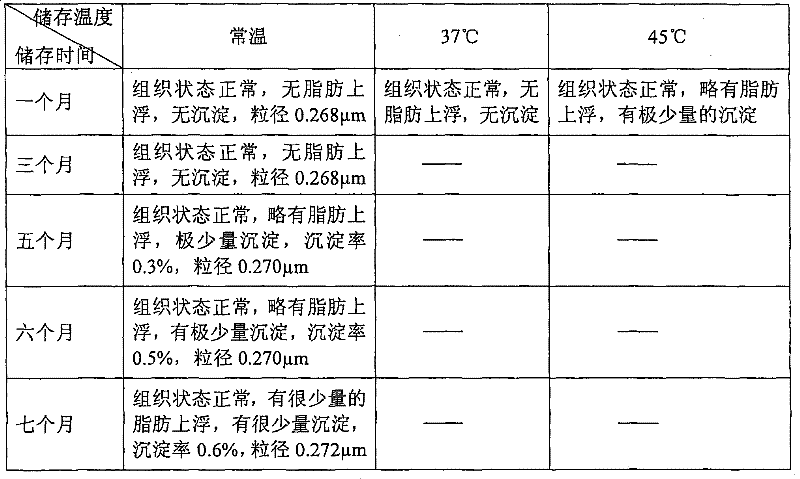

Embodiment 1

[0040] Embodiment 1, full-fat sterilized dairy product and preparation method thereof

[0041] One, prepare the full-fat sterilized milk product of the present embodiment according to the following weight ratios:

[0042] Whole milk 993.5‰, L-carnitine (purchased from Swiss Salon Company) 4.0‰, sodium stearoyl lactylate 1.0‰, sucrose fatty acid glycerides 1.0‰, microcrystalline cellulose 0.2‰, sodium citrate 0.3‰.

[0043] Two, the preparation method of the full-fat sterilized dairy product of the present embodiment

[0044] 1. Milk inspection: It is required that the fat, protein, dry matter and other indicators meet the quality standards of raw milk, and refrigerated below 4°C.

[0045] 2. Ingredients: Put an appropriate amount (15%-20% of the amount of milk used) of milk into the chemical tank, heat it to 60-70°C, add sodium stearoyl lactylate, sucrose fatty acid glyceride and microcrystalline cellulose, and use Stir for 15-20 minutes with shearing and dispersing stirring...

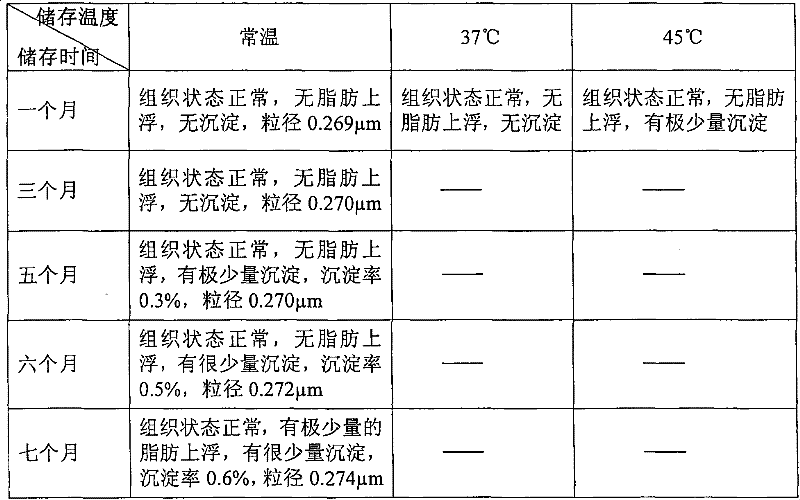

Embodiment 2

[0078] Embodiment 2, low-fat sterilized milk and preparation method thereof

[0079] One, prepare the low-fat sterilized milk of the present embodiment according to the following weight ratios:

[0080] Low-fat milk 994.5‰, L-carnitine 3.0‰, sodium stearoyl lactylate 1.0‰, sucrose fatty acid glycerides 1.0‰, sodium citrate 0.5‰.

[0081] Two, the preparation method of the low-fat sterilized milk of the present embodiment

[0082] 1. Preparation of low-fat milk: Take whole milk (wherein the fat, protein, dry matter and other indicators meet the quality standard requirements of raw milk, and refrigerate below 4°C), pass through a milk separator, and milk fat according to the standard of low-fat milk Separate, prepare the low-fat milk for the topping.

[0083] 2. Ingredients: Pour an appropriate amount (15% to 20% of the amount of milk used) of low-fat milk into the chemical tank, heat it to 60-70°C, add sodium stearoyl lactylate, sucrose fatty acid glyceride, and use a Stirri...

Embodiment 3

[0105] Embodiment 3, skimmed sterilized milk and preparation method thereof

[0106] One, prepare the skimmed sterilized milk of the present embodiment according to the following weight ratios:

[0107] Skimmed milk 996.0‰, L-carnitine 2.0‰, glyceryl monostearate 1.0‰, sucrose fatty acid glyceride 0.5‰, carrageenan 0.1‰, sodium citrate 0.4‰.

[0108] Two, the preparation method of the skimmed sterilized milk of the present embodiment

[0109] 1. Ingredients: Pour most of the skimmed milk into the chemical material tank, heat it to 60-70°C, add glyceryl monostearate, sucrose fatty acid glyceride, and carrageenan, and stir with a stirring device with shearing and dispersing effects 15-20 minutes. Then cool to 50-60°C, add L-carnitine and sodium citrate, continue to stir for about 15 minutes, then cool to below 10°C and pour into the batching tank. In addition, rinse the chemical material tank and pipeline with quantitative milk and put it into the batching tank to make it vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com