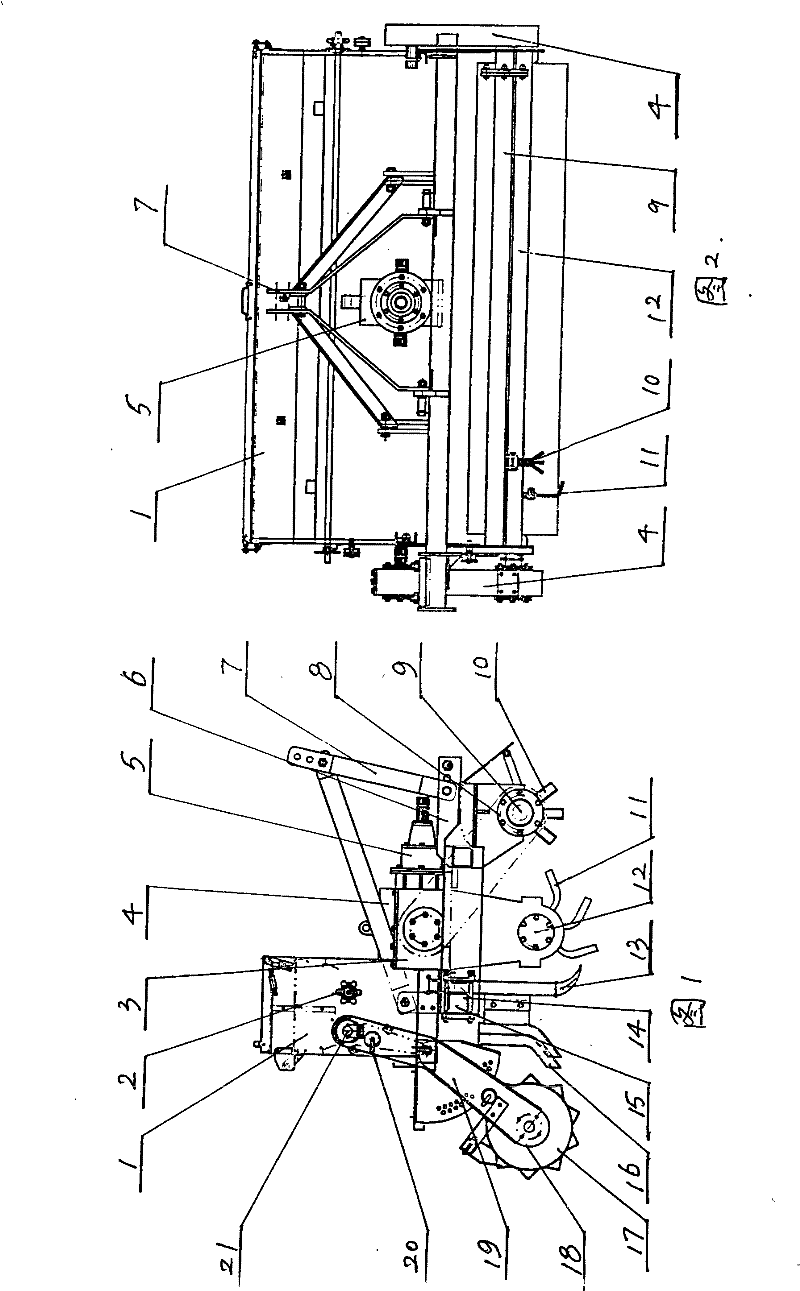

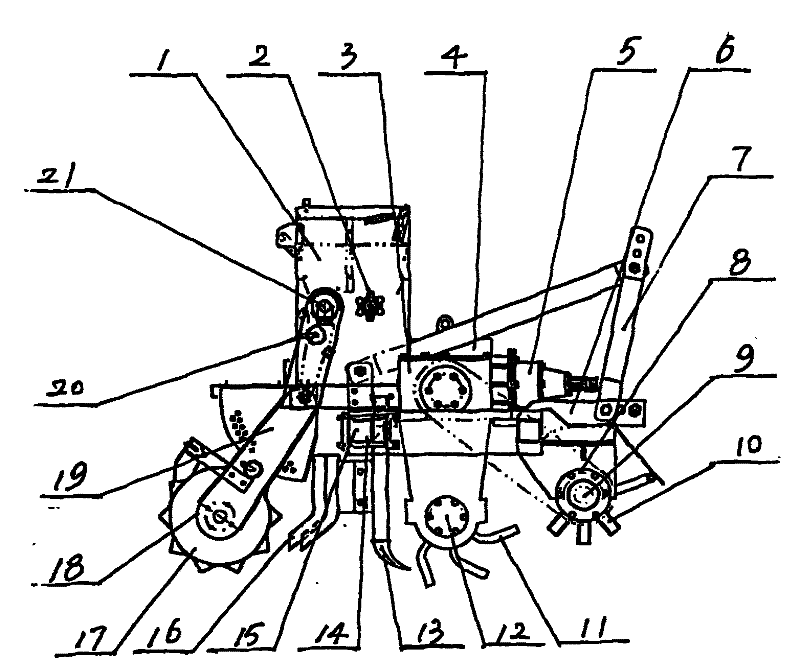

Stalk crushing rotary tillage, fertilizer applying-seeding combined working machine

A straw crushing and working machine technology, which is applied in the fields of tillage equipment, fertilizer and seeding equipment, crop processing machines, etc., to achieve the effect of reducing the number of machines and tools entering the land and tilling times, reducing production costs, and achieving good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The operation process is as follows: start the engine, turn on the hydraulic lift, connect the three-point suspension mechanism of the tractor with the three-point suspension frame 7 of the compound operating machine, lift the compound operating machine about 5-10 cm from the ground, and test run for 5 minutes. Abnormal noise or other abnormal phenomena, the operation is allowed. During the operation, the tractor operator controls the straw crushing height, rotary tillage depth and sowing depth. When the tractor advances, the stalks in front are overwhelmed and thrown up by the stalk crushing knife 10, chopped and thrown downwards, and the rotary tiller 11 buries the chopped stalks in the soil while cutting and crushing the soil. During this process, the rotary tiller chops and covers the stubble remaining in the soil, and the seed meter 21 and the fertilizer discharger 2 powered by the pressure roller 17 work simultaneously to release the predetermined amount of fertil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com