Plated steel wire for PWS excelling in torsion property and process for producing the same

A manufacturing method, a technology of electroplating steel, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of reduced fracture section shrinkage, low production efficiency and pass rate, high frequency of wire breakage, etc., and achieve good torsional characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0116] The following examples are given to illustrate the present invention more specifically, but the present invention is not limited to the following examples, and appropriate changes can be carried out within the scope of the gist of the present invention, and they are all included in the technical scope of the present invention .

[0117] [Sample making method]

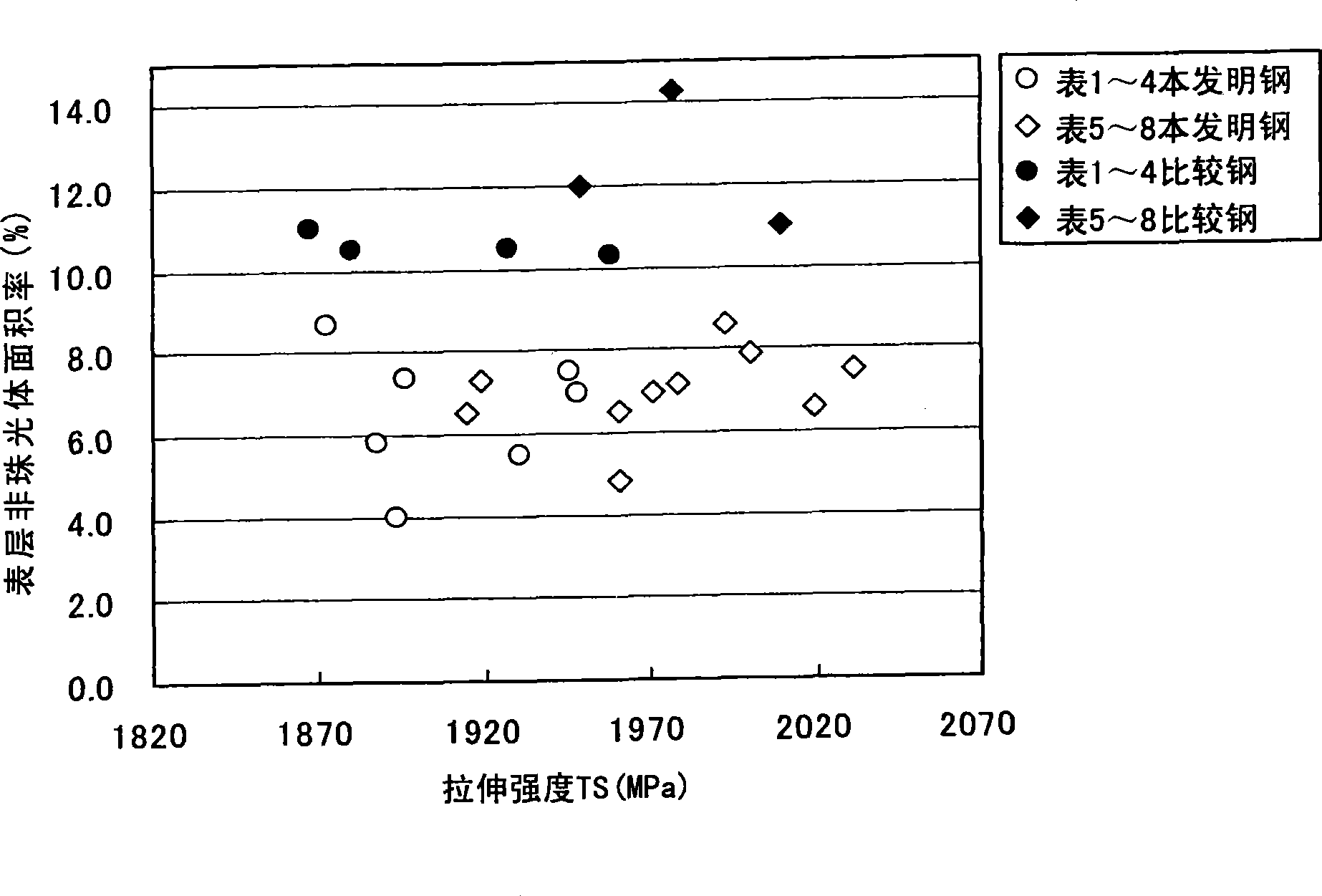

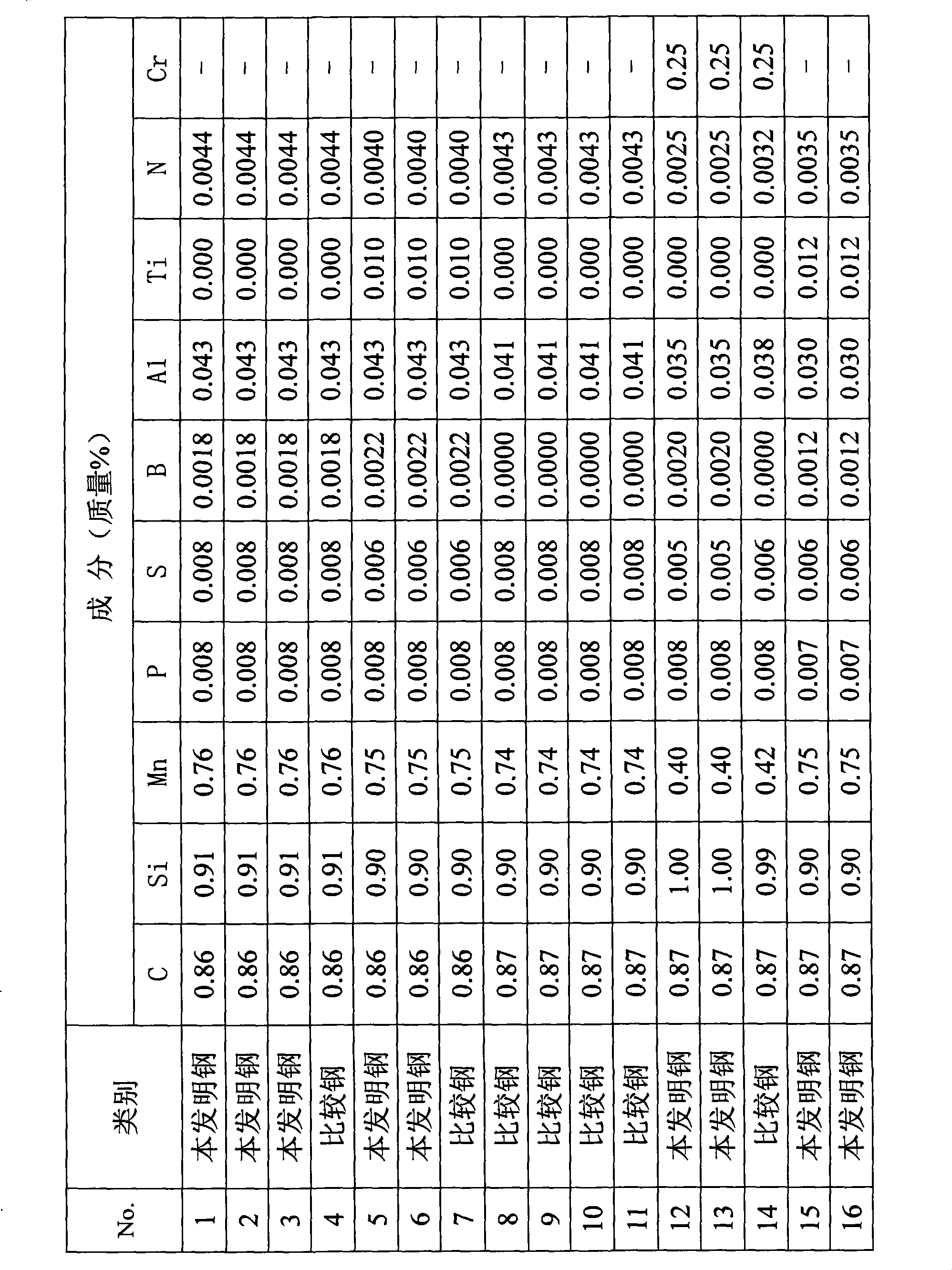

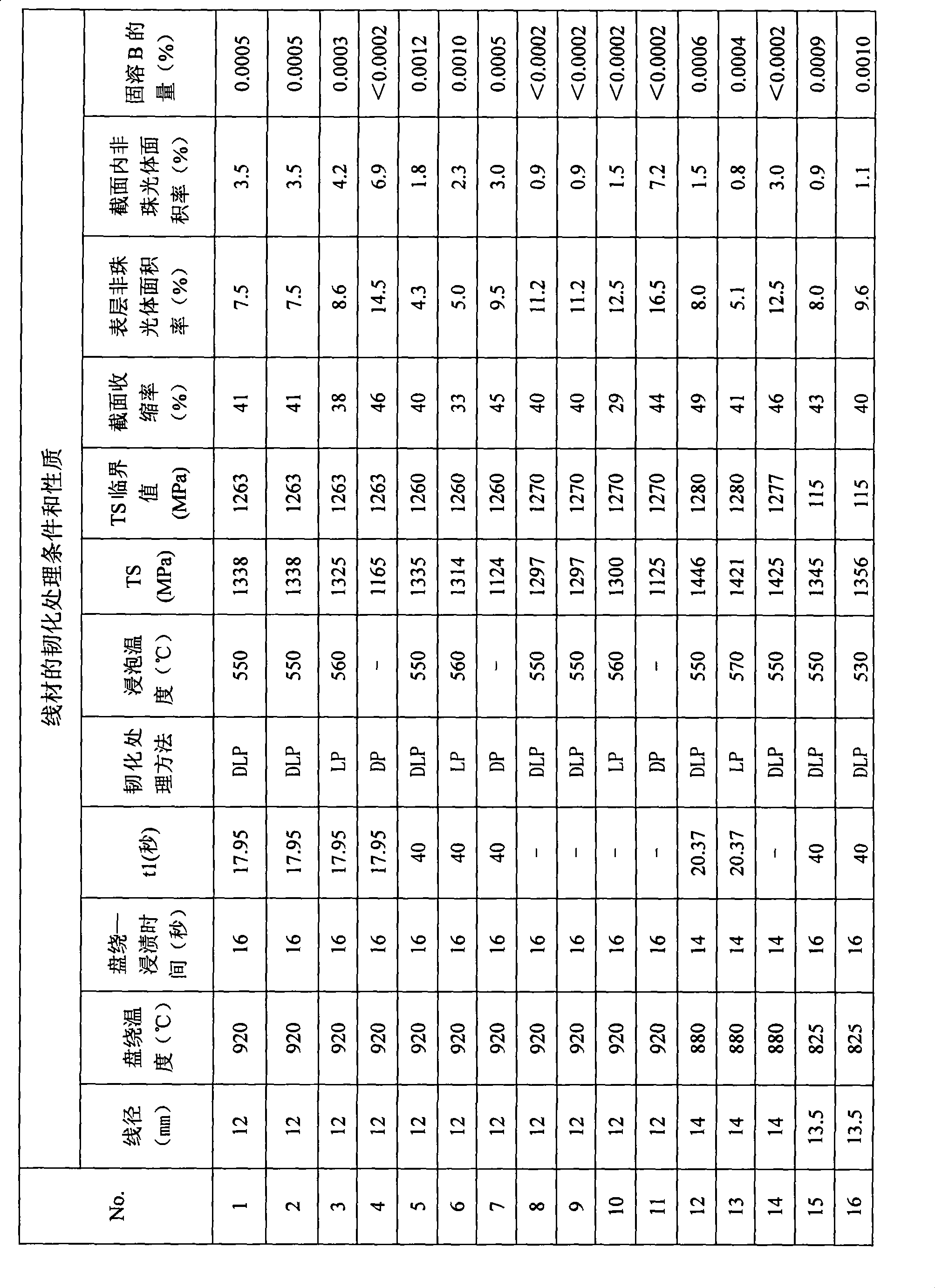

[0118] Table 1, 2 and Table 5, 6 show the chemical composition of the sample material, toughening treatment conditions and mechanical properties of the wire. These sample materials were used to hot-roll into wire rods of predetermined diameters, coiled at predetermined temperatures, and then subjected to direct molten salt toughening (DLP) or reheating molten lead toughening (LP) within a predetermined period of time. At this time, even in Examples with the same composition, the amount of precipitated B nitrides differs depending on the elapsed time from coiling to toughening treatment, so the amount of solid so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com