Transforming plant assembly type cable slot body and spreading method

A cable trench and prefabricated technology, applied in the direction of cable installation, ground cable installation, cable laying equipment, etc., can solve the problems that hinder the popularization and application of fully assembled substations, shorten the construction period, and large settlement, and achieve good promotion and application value , The effect of increasing labor productivity and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

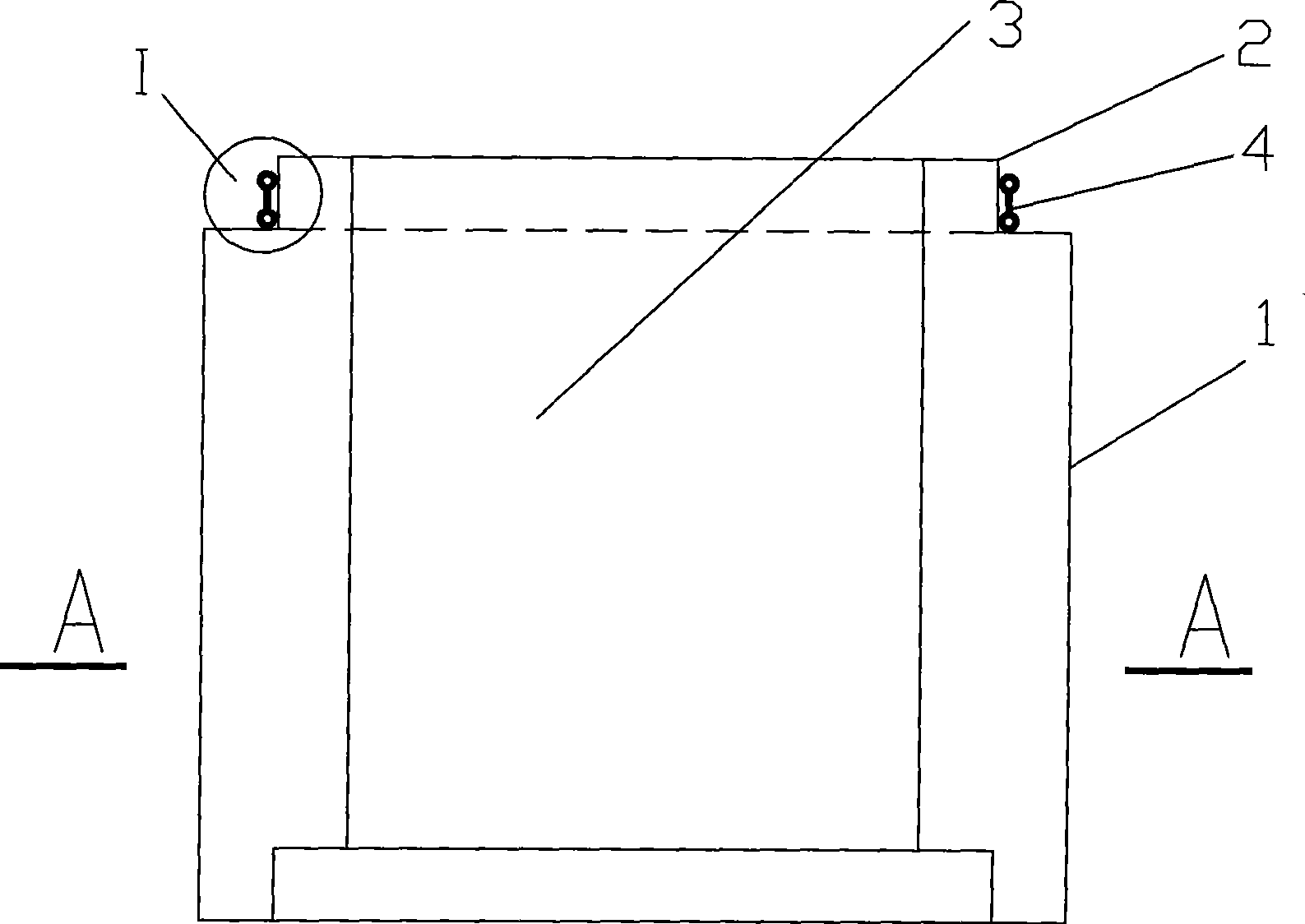

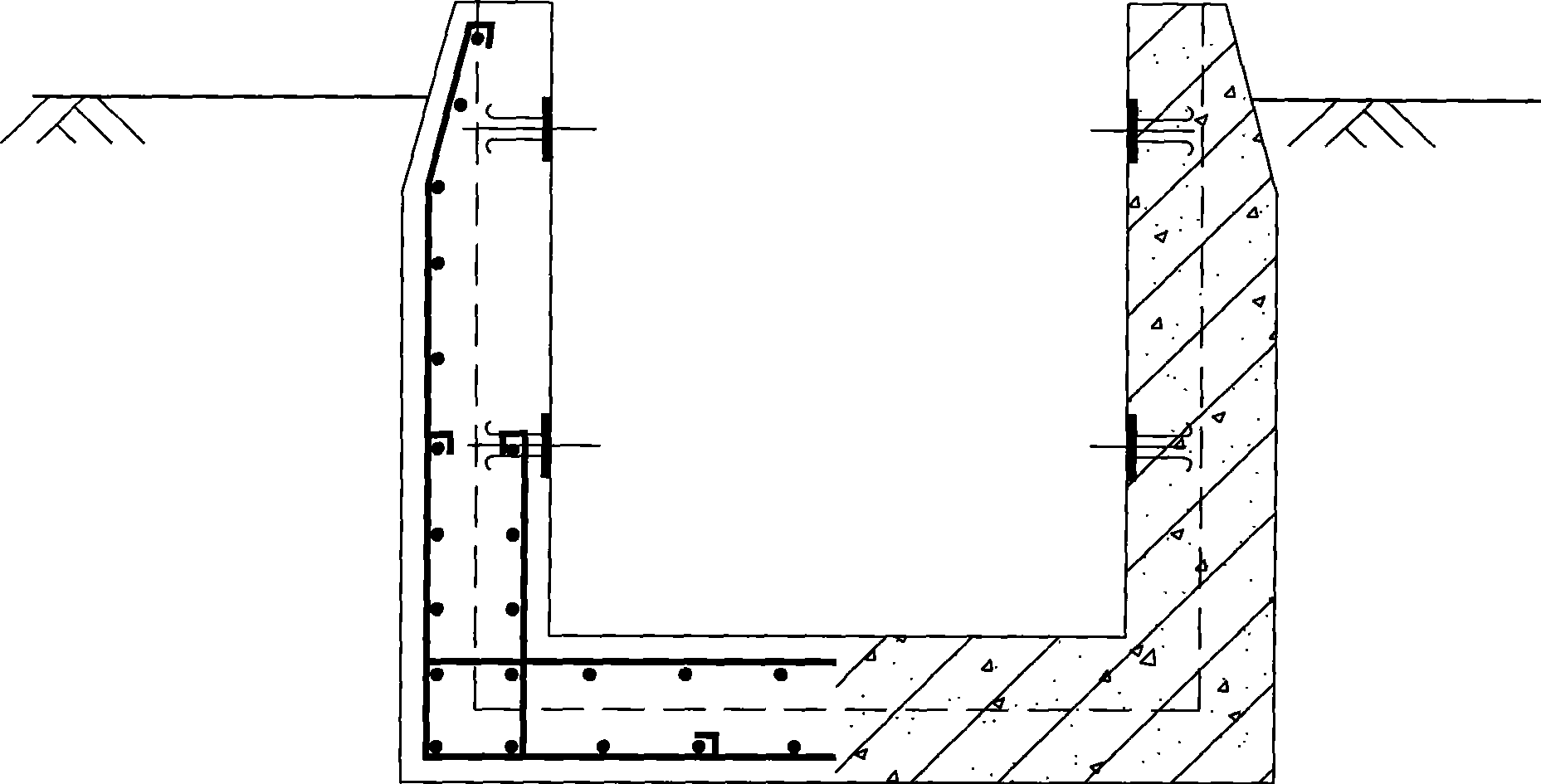

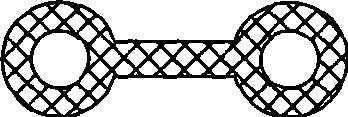

[0021] Embodiment 1, the main components of the present invention are: C30-C40 reinforced concrete or steel fiber concrete (appearance grade of fair-faced concrete) and rubber strips with double-P appearance that slightly expand when exposed to water.

[0022] Production: Customized steel molds are used, and the prefabricated site area on the construction site is factory-made on-site, moisturizing, heat-preserving and maintenance; the double-P appearance micro-expanding rubber strips are custom-processed and produced by professional manufacturers.

[0023] Installation: (1) First, on the conventional C15 plain concrete cushion, dry cement sand with a thickness of 100mm is used for leveling the assembled cable trench body after installation; (2) Use the P200 excavator standing on the site for transportation and Installation; (3) When connecting, make full use of the lap groove invented by the assembled cable trench body, install it up and down, and press the double P appearance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com