Decompression valve for precipitator

A technology of dust collector and pressure relief valve, applied in the direction of safety valve, balance valve, valve device, etc., can solve the problems of reducing the service life of the dust collector, the suction and deformation of the dust collector shell, affecting the normal operation of the dust collector, etc. Normal operation, ensure the effect of deformation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

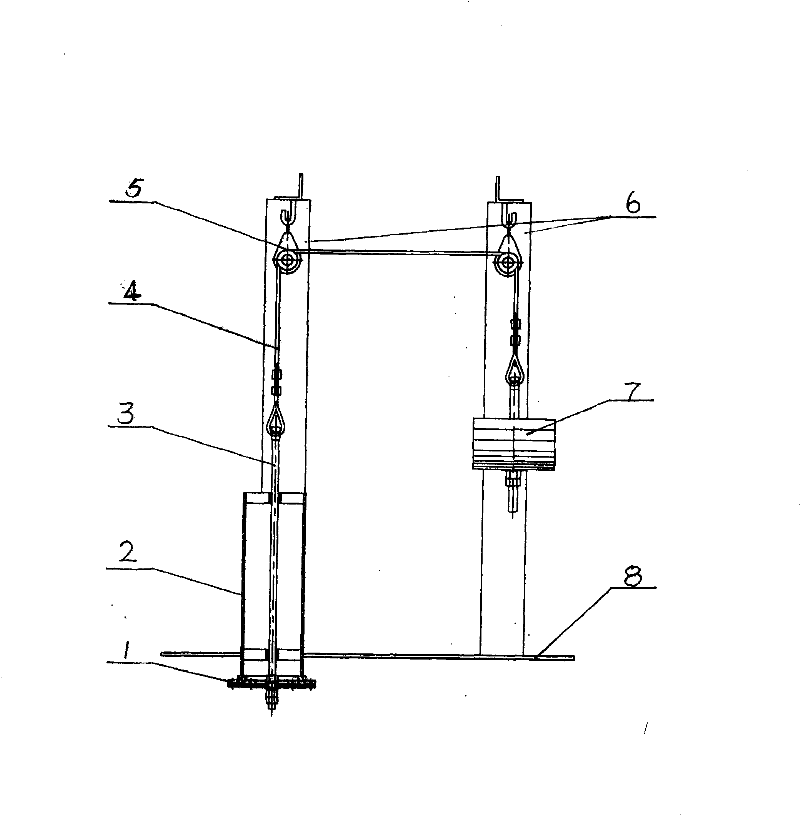

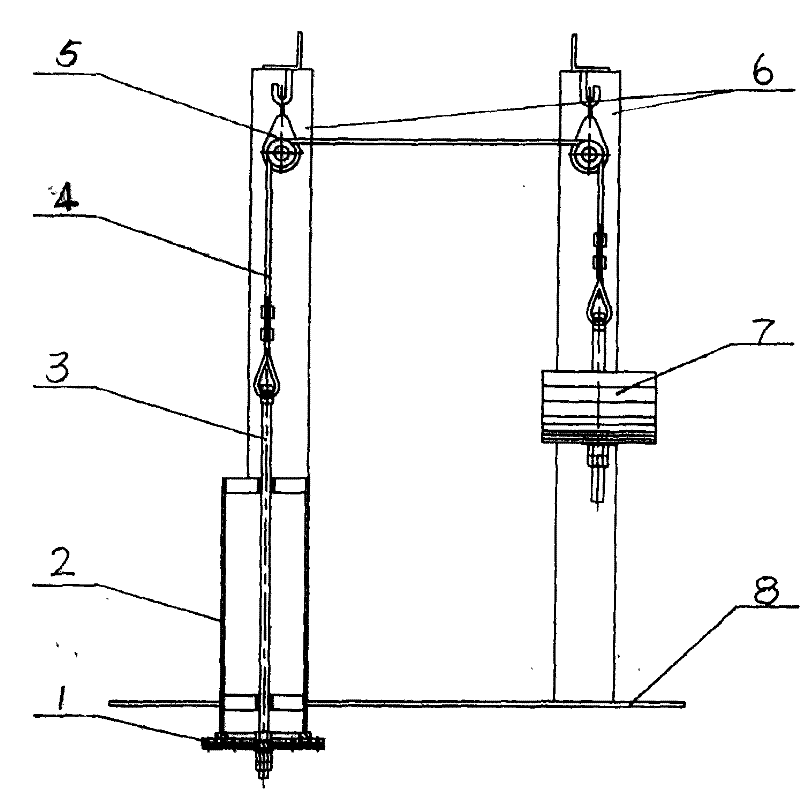

[0010] The pressure relief valve of the present invention that is used for dust remover as shown in the accompanying drawing is made up of valve plate 1, guide rod 3, valve body 2, steel wire rope 4, pulley 5, bracket 6 and counterweight 7, and valve body 2 is installed in the dust remover On the housing 8, one end of the guide rod 3 passes through the valve body 2 and is connected to the valve plate 1 placed in the housing 8, and the other end of the guide rod 3 is connected to the counterweight 7 through the steel wire rope 4; The bracket 6 is fixed in the groove of the pulley 5 on the housing 8.

[0011] During industrial manufacturing, the valve plate 1 is first connected to one end of the guide rod 3, and the other end of the guide rod 3 passes through the valve body 2 and the cover plate, and then the valve body 2 is put into the hole processed in the dust collector housing 8. In the inner part, the valve plate 1 is placed in the dust collector housing 8, and the valve b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com