Method for restraining flow separation in transition section by utilizing guide vane

A technology of guide vanes and transition sections, which is applied in the field of using guide vanes to suppress flow separation in the transition section, and can solve problems such as increasing system complexity and increasing engine weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

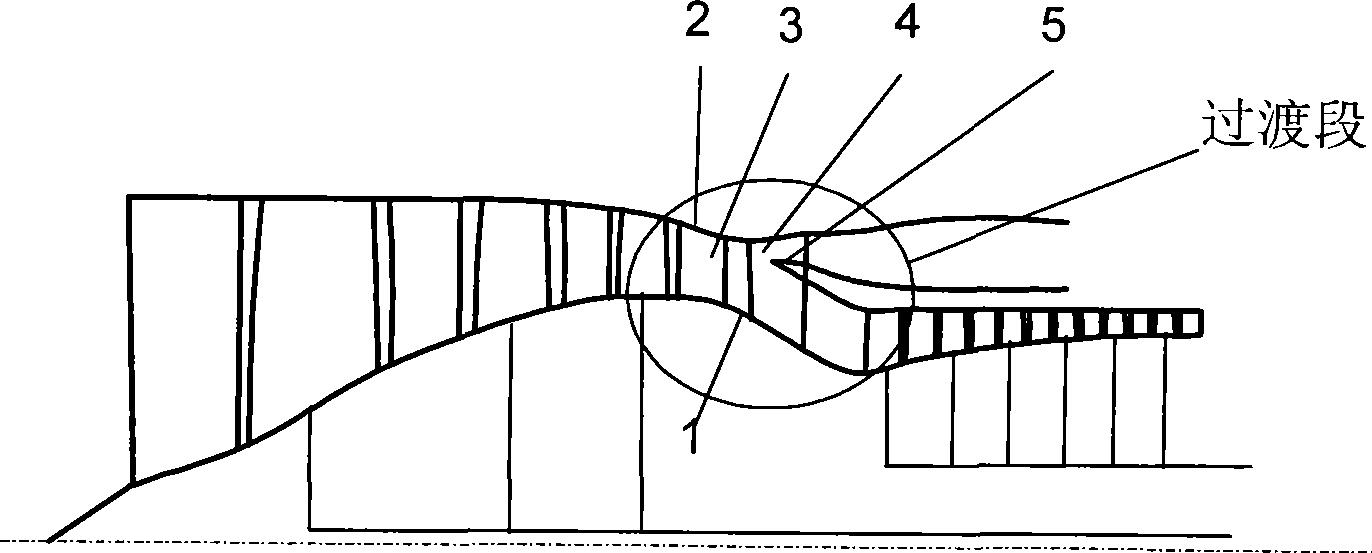

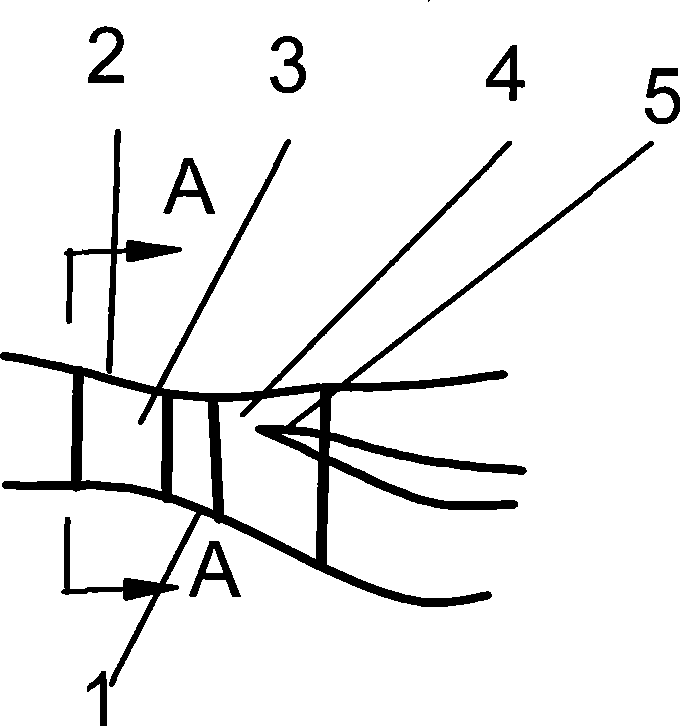

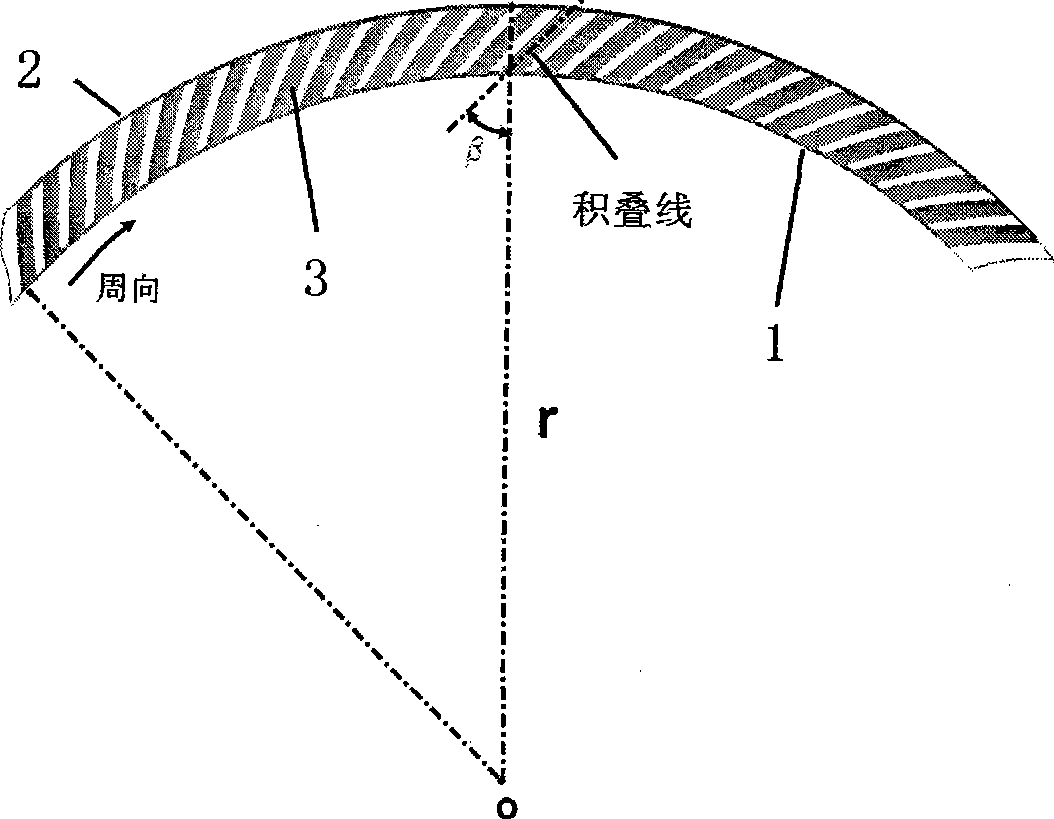

[0014] In order to describe the present invention more clearly, this specific embodiment takes a method for suppressing flow separation in a transition section as an example, and further illustrates the present invention with reference to the accompanying drawings.

[0015] The first is to determine the installation position of the guide vane. In this example, the transition section structure see figure 2 , the total length of the transition section is 0.35m, and the axial chord length of the guide vane is 0.06m. The maximum curvature of the first bend of the transition section is located at 0.064m from the entrance of the transition section, making it 0.6 times the axial chord length from the leading edge of the guide vane, and the leading edge of the guide vane is located at 0.04m from the entrance of the transition section Position, the trailing edge is located 0.1m away from the entrance of the transition section.

[0016] The second is to determine the angle between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com