Tube type precipitation reactor

A reactor and pipeline technology, applied in chemical methods, chemical instruments and methods, chemical/physical processes, etc., for the reaction of liquids with liquids, etc. Few factors, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] At present, the method for preparing luminescent grade strontium carbonate in industry is mainly the conventional precipitation method, but in the production process of the conventional precipitation method, especially when the reaction kettle is large, plus human factors, the size of the strontium carbonate precipitated particles and its The control of the distribution is not very ideal, and the stability of the batch is not good.

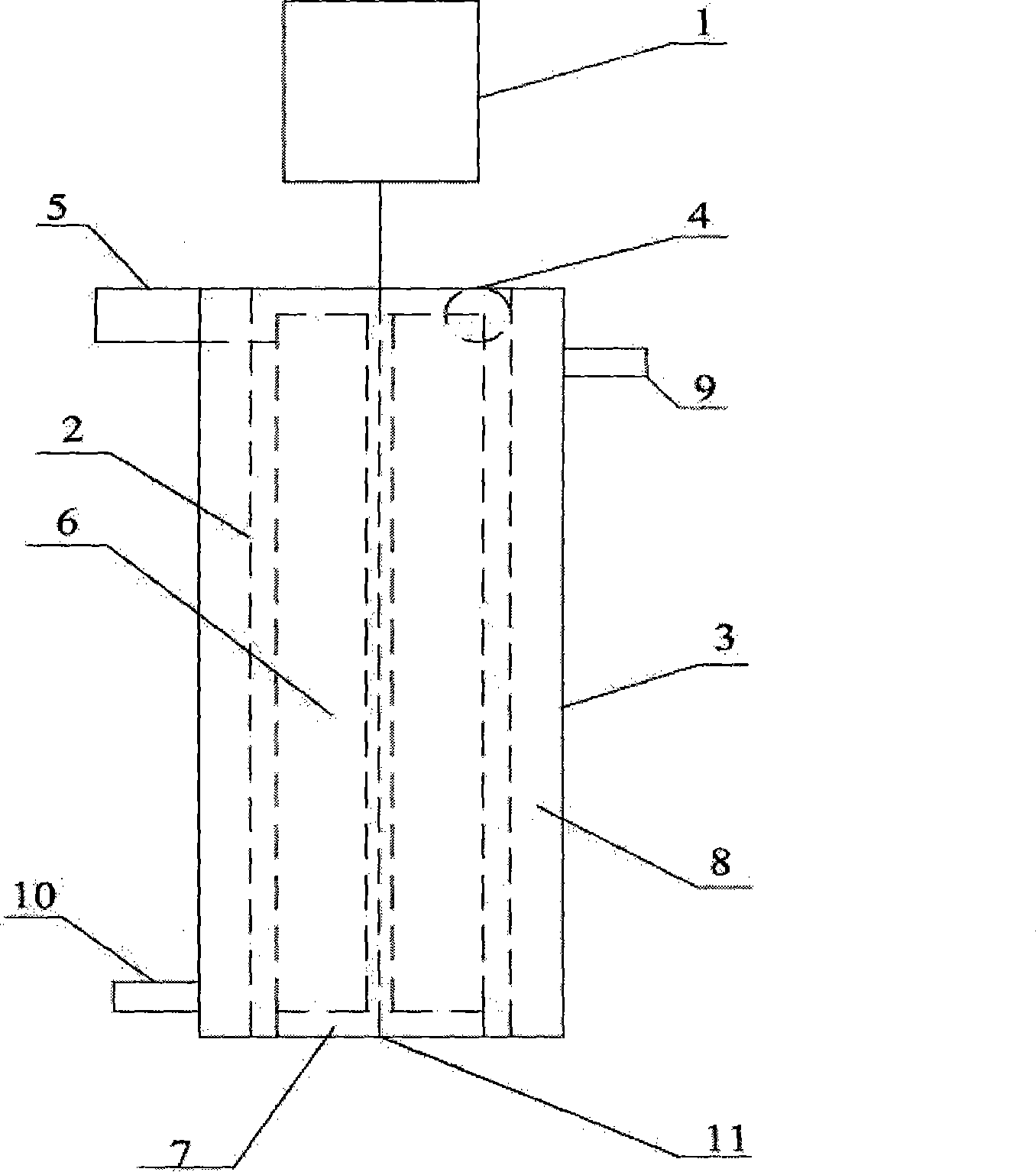

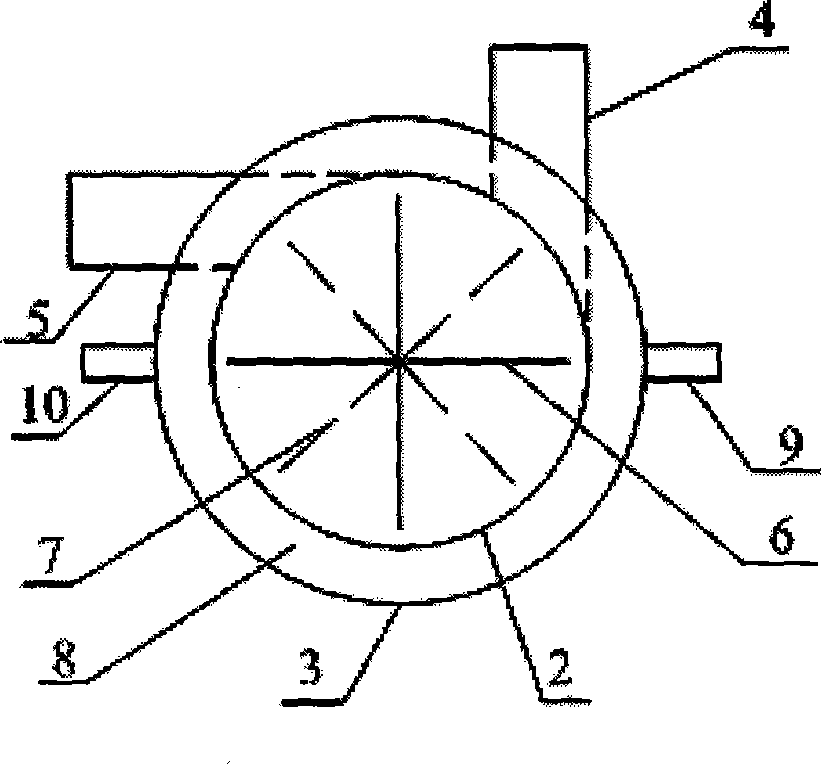

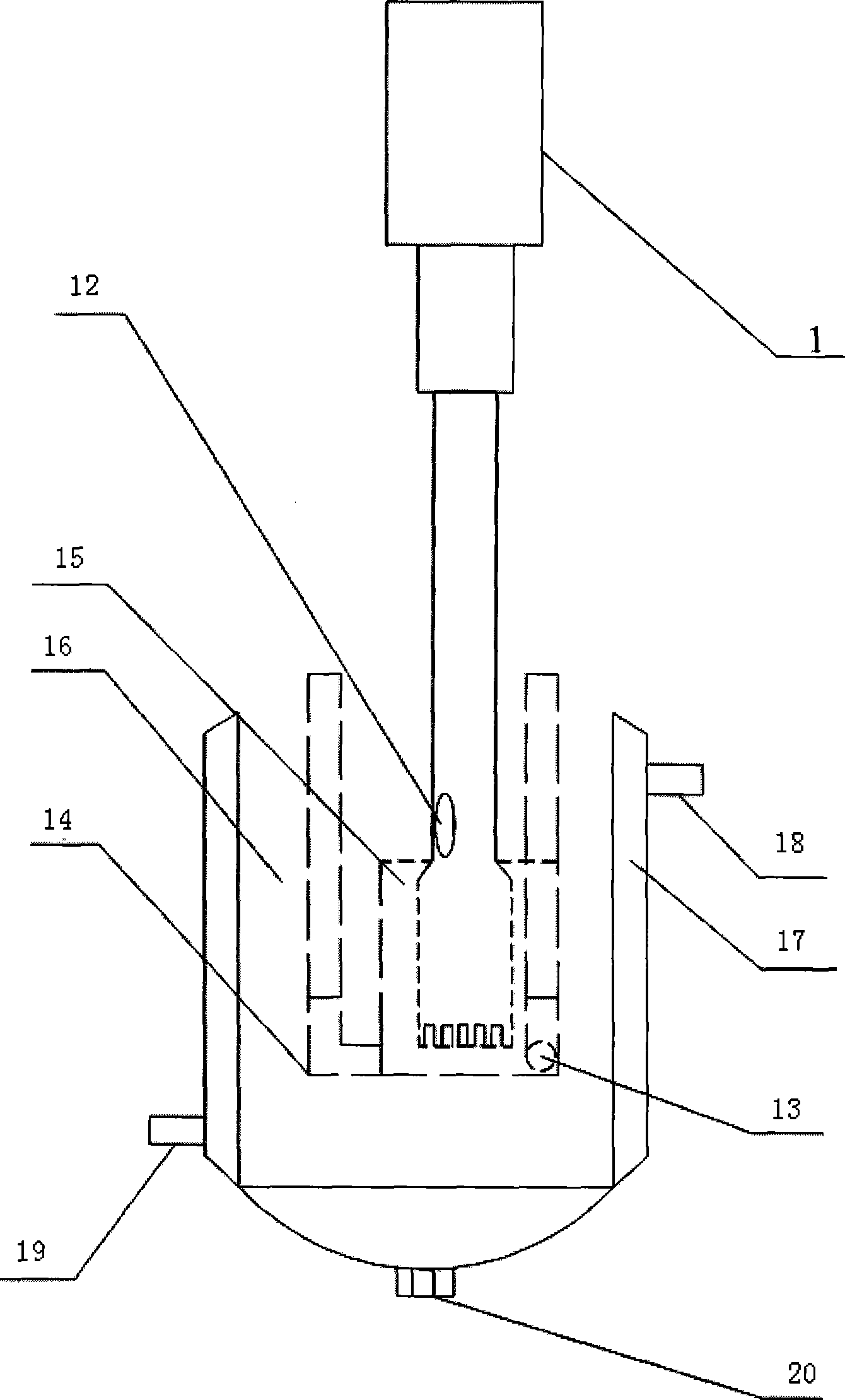

[0024] Using this pipeline precipitation reactor, the reactant Na 2 CO 3 solution and SrCl 2 The solution is passed through the constant pressure feeder by figure 1 The feed inlets (4), (5) enter the pipe of the pipeline precipitation reactor, and under the high-speed rotation of the impeller, the two feed liquids are instantly mixed and reacted in the pipe to generate SrCO 3 Precipitate, and discharge from the outlet at the bottom of the pipeline precipitation reactor into the stirring reactor, which has been added with dilute dispersan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com