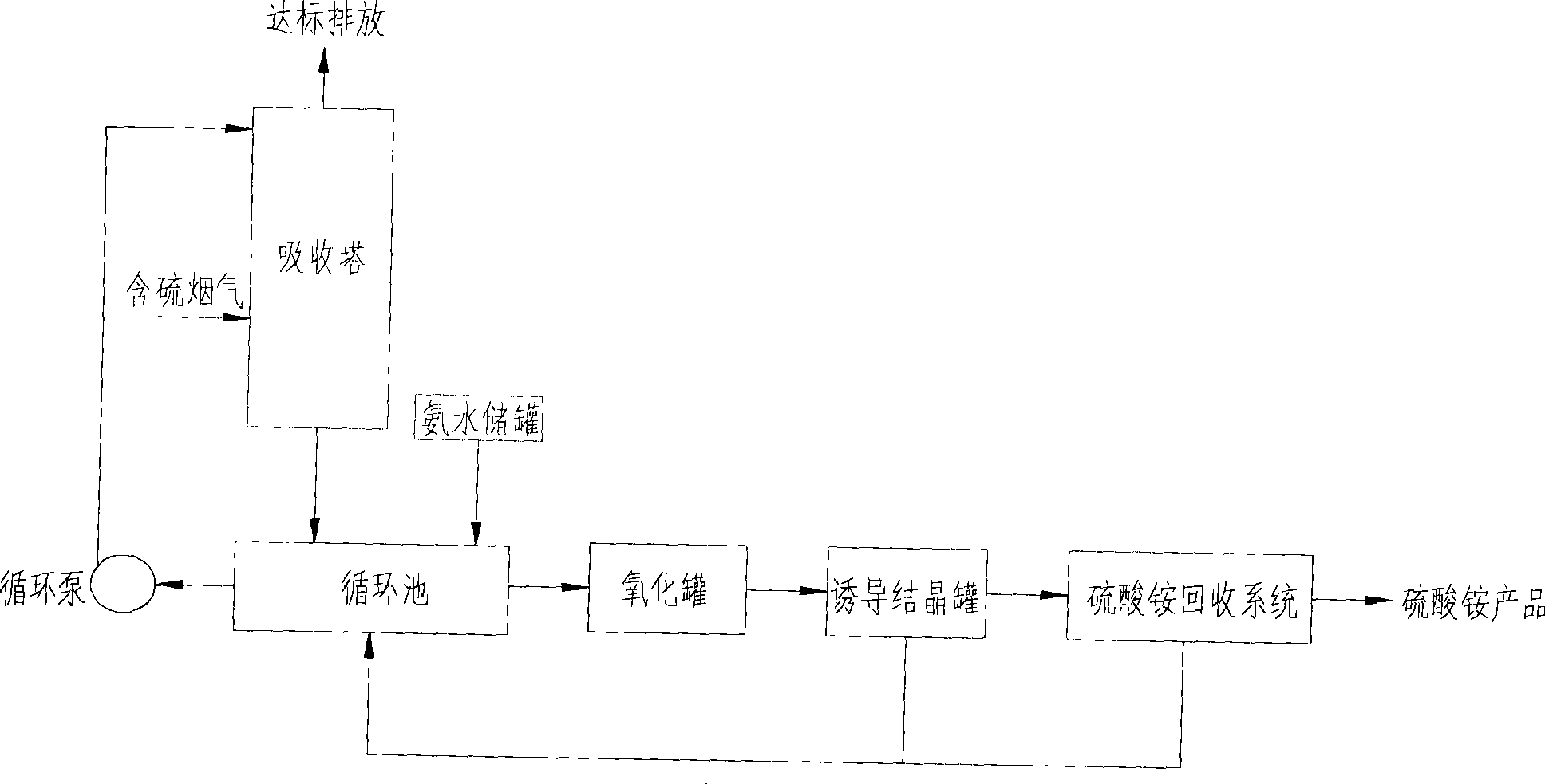

Ammonia-ammonium sulphate wet-method flue-gas desulfurization and ammonium sulphate recovery technique using induced crystallization

A technology of wet flue gas desulfurization and induced crystallization, which is applied in the environmental field, can solve the problems of high production cost of ammonium sulfate recovery, low ammonia utilization rate, and low cost of recovery ammonium sulfate, so as to reduce steam consumption, save operating costs, and reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The flue gas temperature is 150℃, the imported SO 2 The concentration is 2000ppm, the saturated ammonium sulfate solution is used as the absorption liquid, the pH value of the absorption liquid in the circulating tank is 5, and the liquid-to-gas ratio to the flue gas is 3.0L / m 3 , The amount of the bottom effluent returning to the desulfurization absorber accounts for the percentage of the total exhaust, that is, the reflux ratio is 90%, and the seed crystal is induced to be an appropriate amount of SiO 2 .

[0030] After the entire system runs, the flue gas desulfurization efficiency reaches 90%, and the purity of ammonium sulfate is 95%.

Embodiment 2

[0032] The flue gas temperature is 130℃, imported SO 2 The concentration is 4000ppm, the saturated ammonium sulfate solution is used as the absorption liquid, the pH value of the absorption liquid in the circulating tank is 5.2, and the liquid-to-gas ratio to the flue gas is 5.0L / m 3 , The amount of the bottom effluent returning to the desulfurization absorber accounts for the percentage of the total exhaust, that is, the reflux ratio is 95%, and the induced seed crystal is an appropriate amount (NH 4 ) 2 SO 4 .

[0033] After the entire system runs, the flue gas desulfurization efficiency reaches 93%, and the purity of ammonium sulfate is 92%.

Embodiment 3

[0035] The flue gas temperature is 140℃, the imported SO 2 The concentration is 1500ppm, the saturated ammonium sulfate solution is used as the absorption liquid, the pH value of the absorption liquid in the circulating tank is 5.5, and the liquid-to-gas ratio to the flue gas is 1.5L / m 3 , The amount of the bottom effluent returning to the desulfurization absorber accounts for the percentage of the total exhaust, that is, the reflux ratio is 85%, and the seed crystal is induced to be an appropriate amount of SiO 2 , (NH 4 ) 2 SO 4 , CaCO 3 mixture.

[0036] After the entire system runs, the flue gas desulfurization efficiency reaches 94%, and the purity of ammonium sulfate is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com