Airbag fabric

A technology of fabrics and airbags, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of no structure, unreliable seams, too large, etc., and achieve high coverage factor, reduced manufacturing cost, and small leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

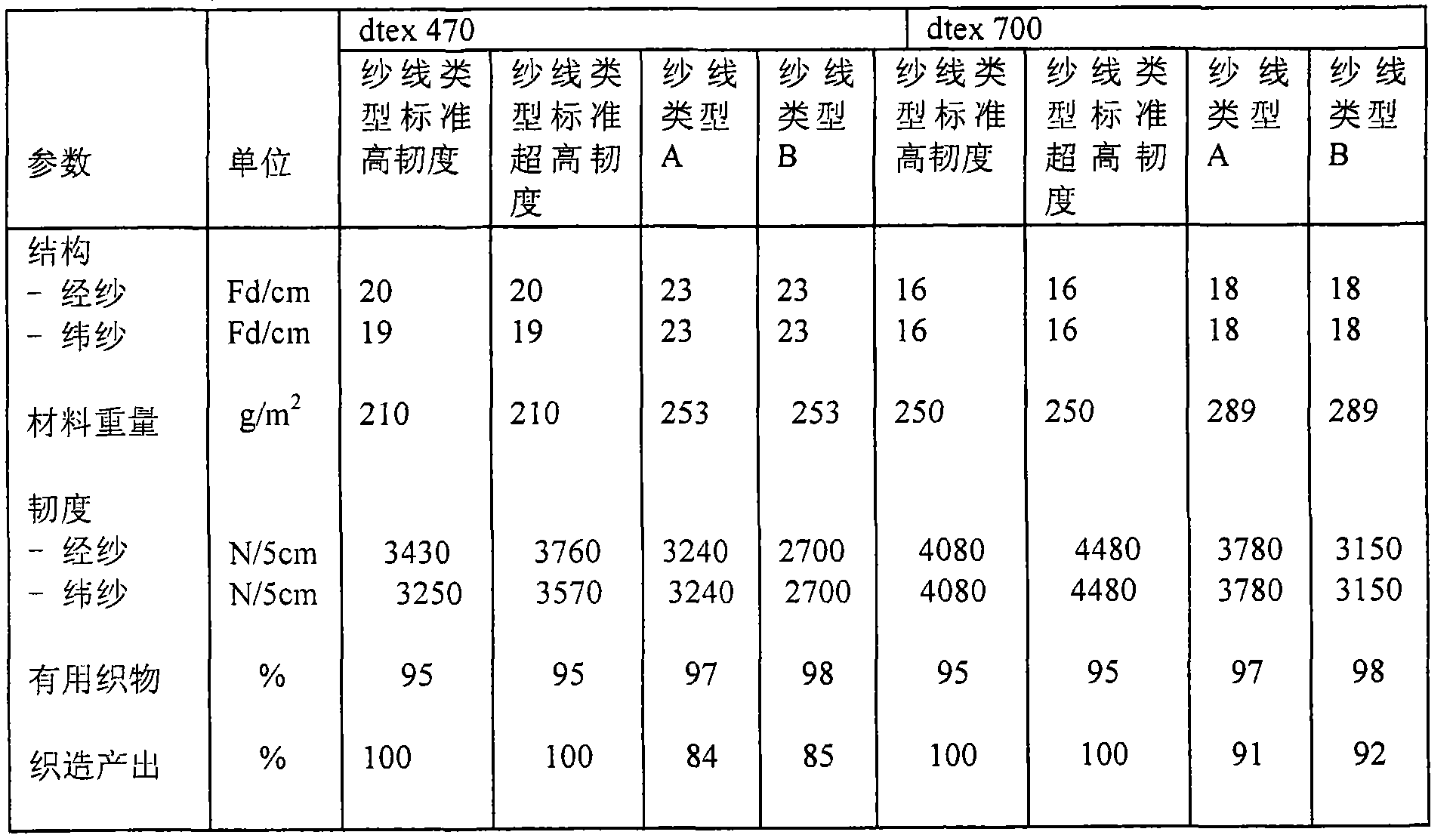

[0064] Exemplary aspects of fabrics according to the invention

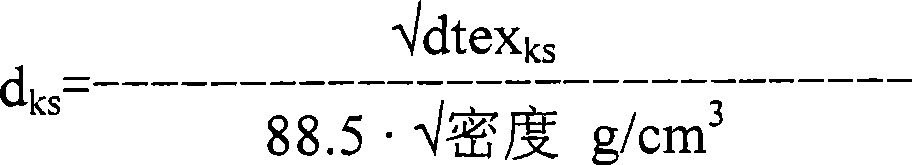

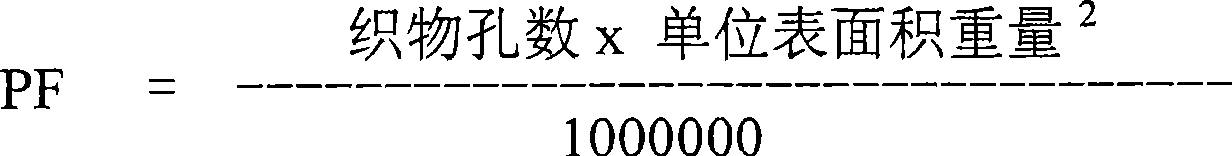

[0065] The fabric parameters shown in the figure below are pre-calculated:

[0066]

[0067] The fabrics are all L1 / 1 plain weave. As mentioned above, the high-density uncoated fabric improves seam sealing because it optimizes the venting of gas through the wall surfaces of the bag by increasing the air permeability under increased internal pressure so that the gas vents in a controlled manner , and in the case of maintaining the load, it returns to approximately zero when the pressure disappears. In the case of tight joints, this particle retention effect can only be controlled by the wall surface.

[0068] Due to the processing of textile airbags according to the corresponding vehicle, the inflator in use and the seam structure, various yarns with different tenacity, stretch and workability are used to process high-density fabrics, so that As far as the processing structure is concerned, the deployment re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com