Device and method for testing accurate servo linear drive system performance

A test device and system performance technology, applied in measurement devices, general control systems, control/regulation systems, etc., can solve problems such as difficulty in forming performance expression and evaluation methods for servo systems, and inability to establish industry standards, and achieve ingenious design and performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

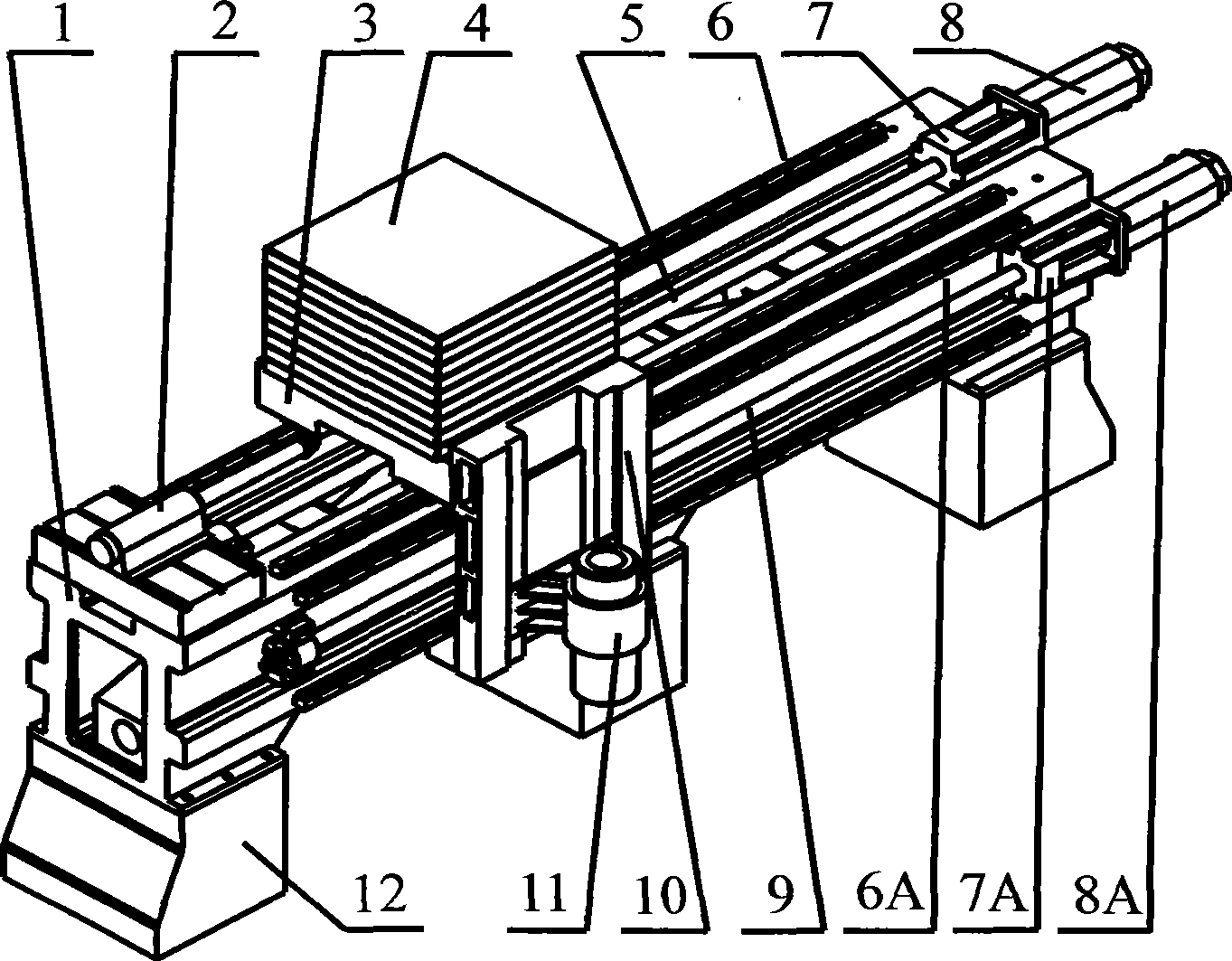

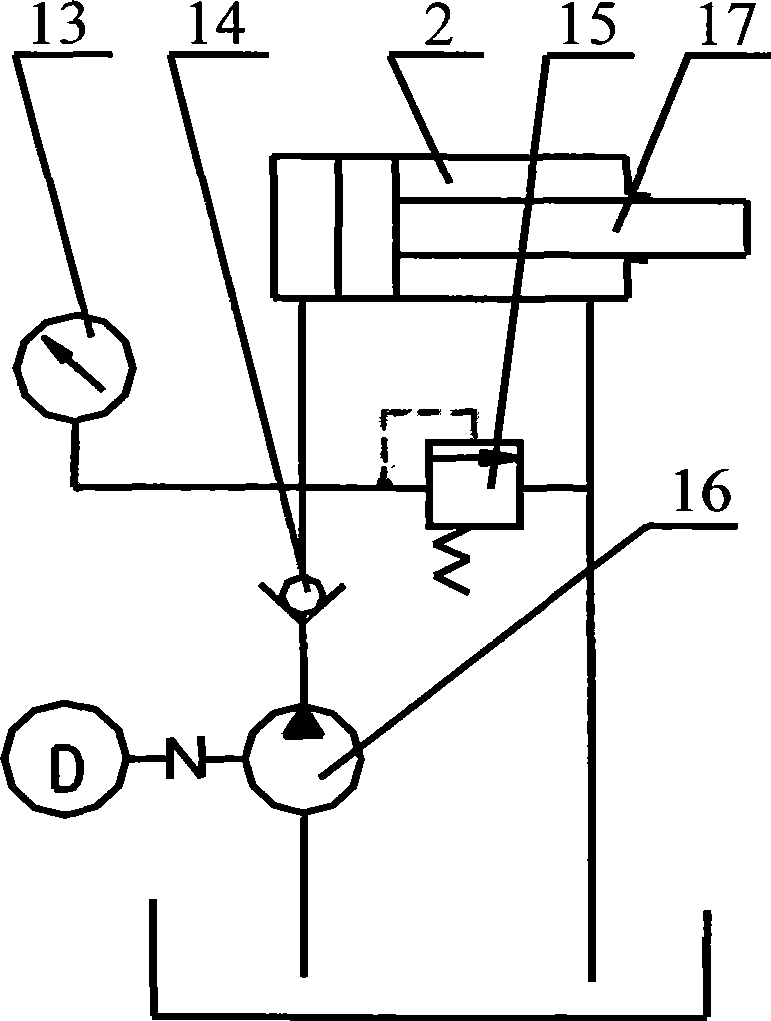

[0035] The structure diagram of the present invention is as figure 1 , 2 As shown, it includes the bed foot 12 and the bed 1 supported on the bed foot 12, wherein the bed 1 is equipped with the main screw guide rail pair 5 and the auxiliary screw guide rail pair 9, the main servo motor 8 and the auxiliary servo motor 8A They are respectively installed on the main servo motor mounting base 7 and the auxiliary servo motor mounting base 7A, and are respectively connected with the screw rods of the main screw guide rail pair 5 and the auxiliary screw guide rail pair 9 through couplings, and the workbench 3 and the auxiliary working table The table 10 is respectively installed on both sides of the bed 1, and the screw nuts in the main screw guide pair 5 and the auxiliary screw guide rail pair 9 that drive the movement of the worktable 3 and the auxiliary worktable 10 are fastened on the worktable 3 and the auxiliary worktable. Below the workbench 10, loads 4 of various masses and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com