Method for co-firing ceramic sensing head substrate and platinum gold electrode of oxygen sensor

A technology of oxygen sensor and sensing head, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of platinum electrode layer blocking, easy falling off, and poor adhesion of ceramic sensing head substrate, so as to reduce the probability of peeling off and improve Adhesion and the effect of improving thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

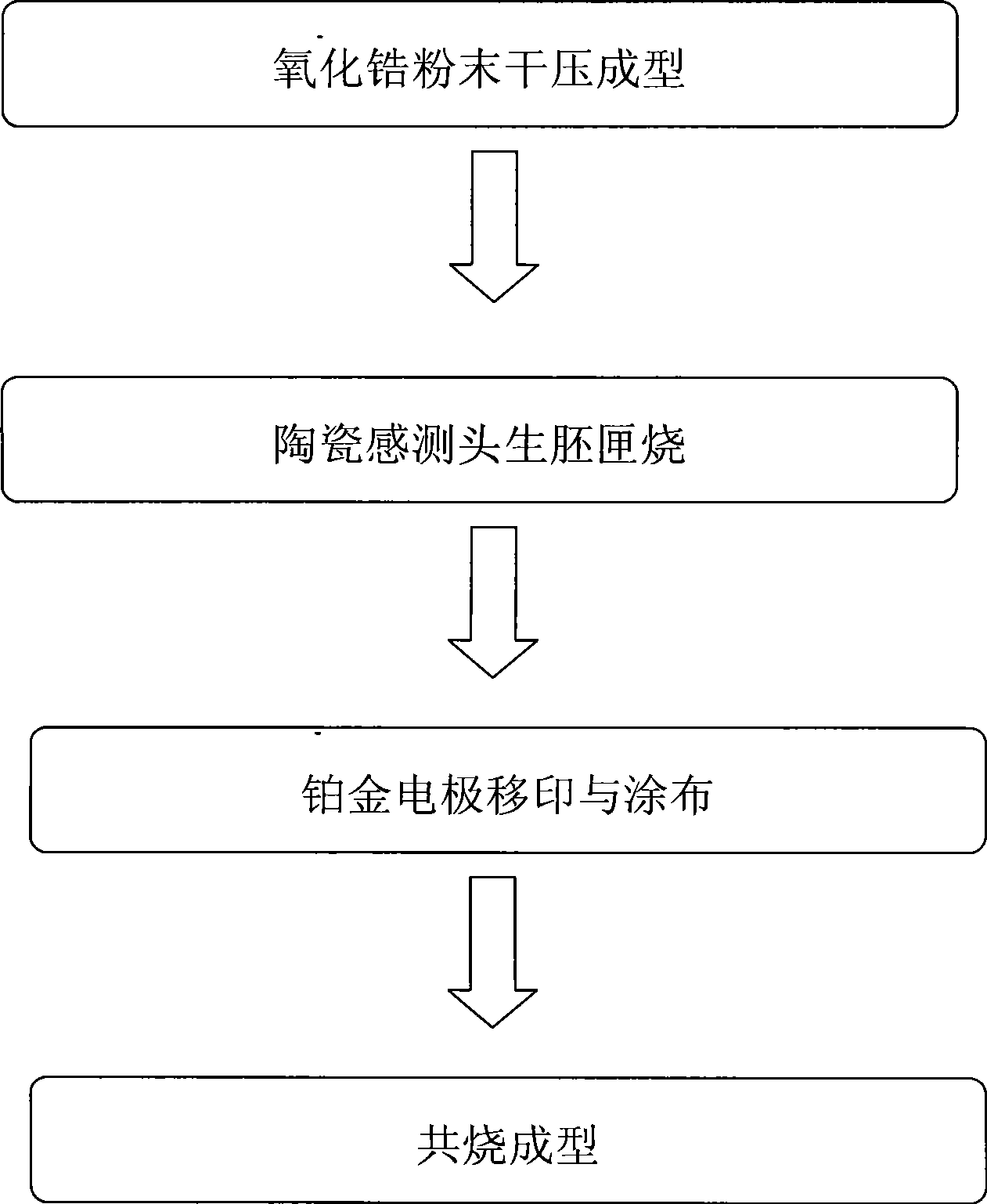

[0025] The core idea of the present invention is: in the present invention, the ceramic sensing head green body formed by powder dry pressing is fired to completely remove the binder in the matrix, and then the platinum electrode layer is coated on the surface of the ceramic sensing head matrix, and then Platinum internal and external electrodes were prepared on the base of the ceramic sensing head by coating method and pad printing method respectively, and finally the base of the ceramic sensing head was co-fired in a high-temperature sintering furnace to prepare a ceramic sensing head of an oxygen sensor containing platinum electrodes.

[0026] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

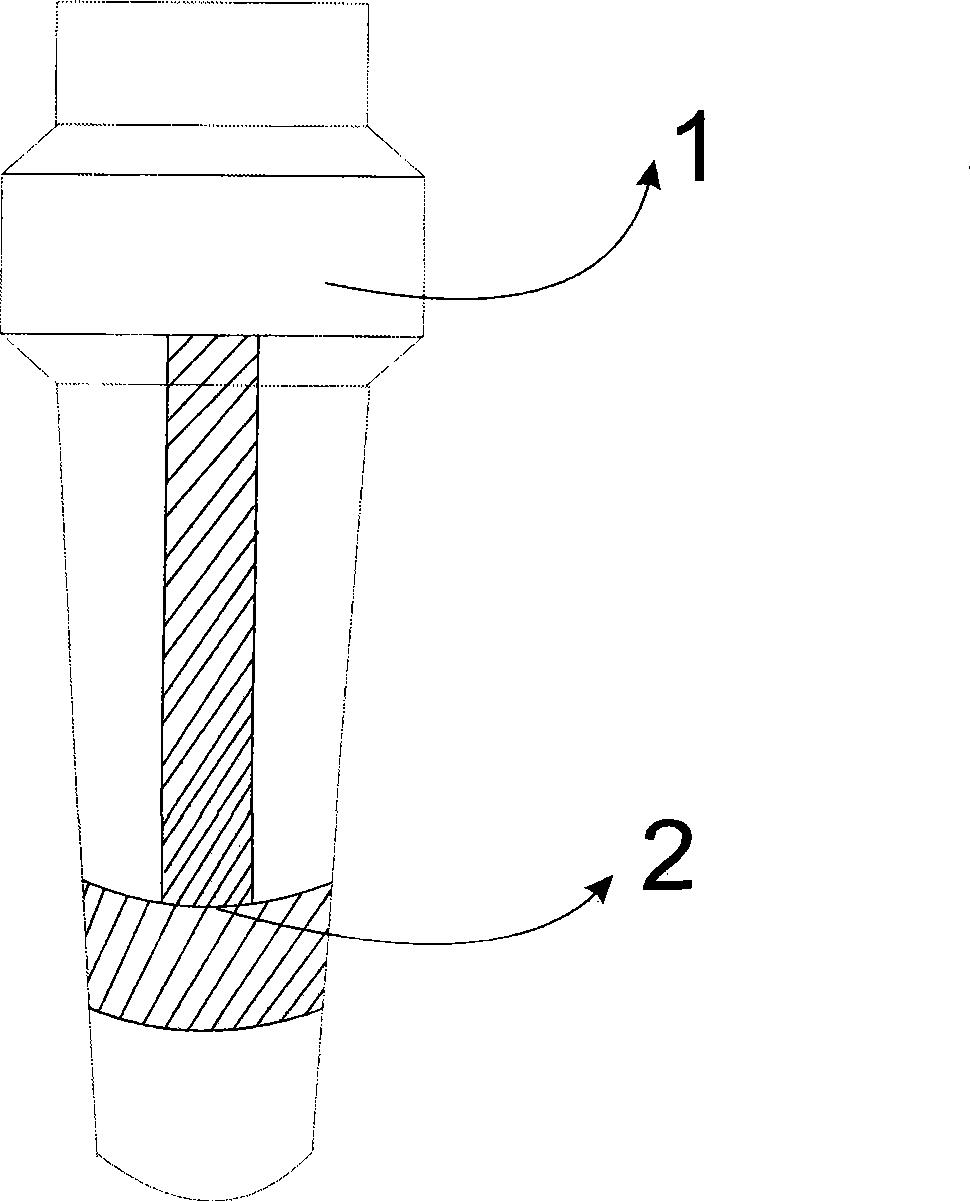

[0027] Such as figure 1 As shown, the green body of the sleeve-shaped ceramic sensing head base 1 is prepared through a powder dry press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com