Automatic calibration system and method of resistance absorbing instrument

An automatic calibration, standard rod technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as drift, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

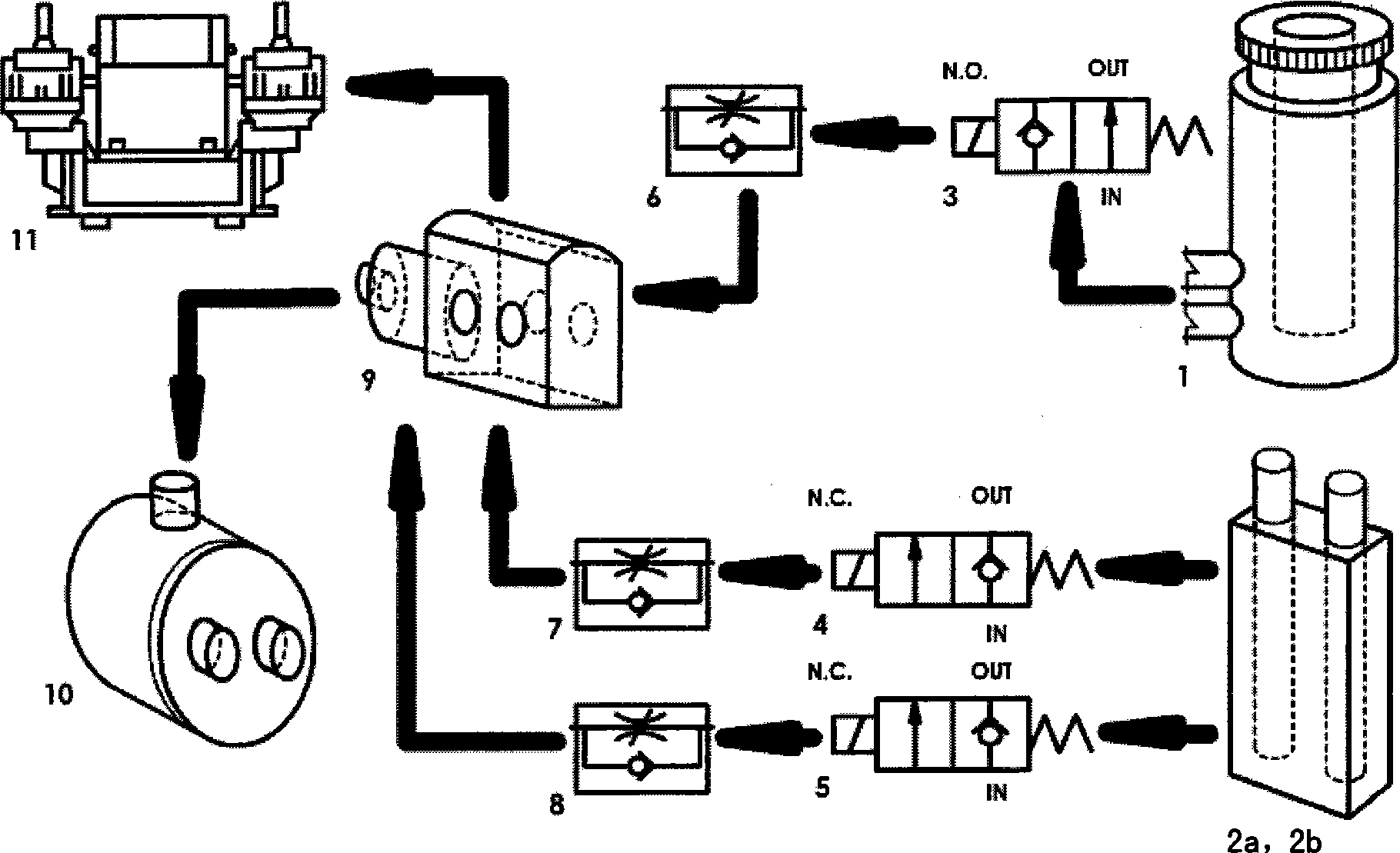

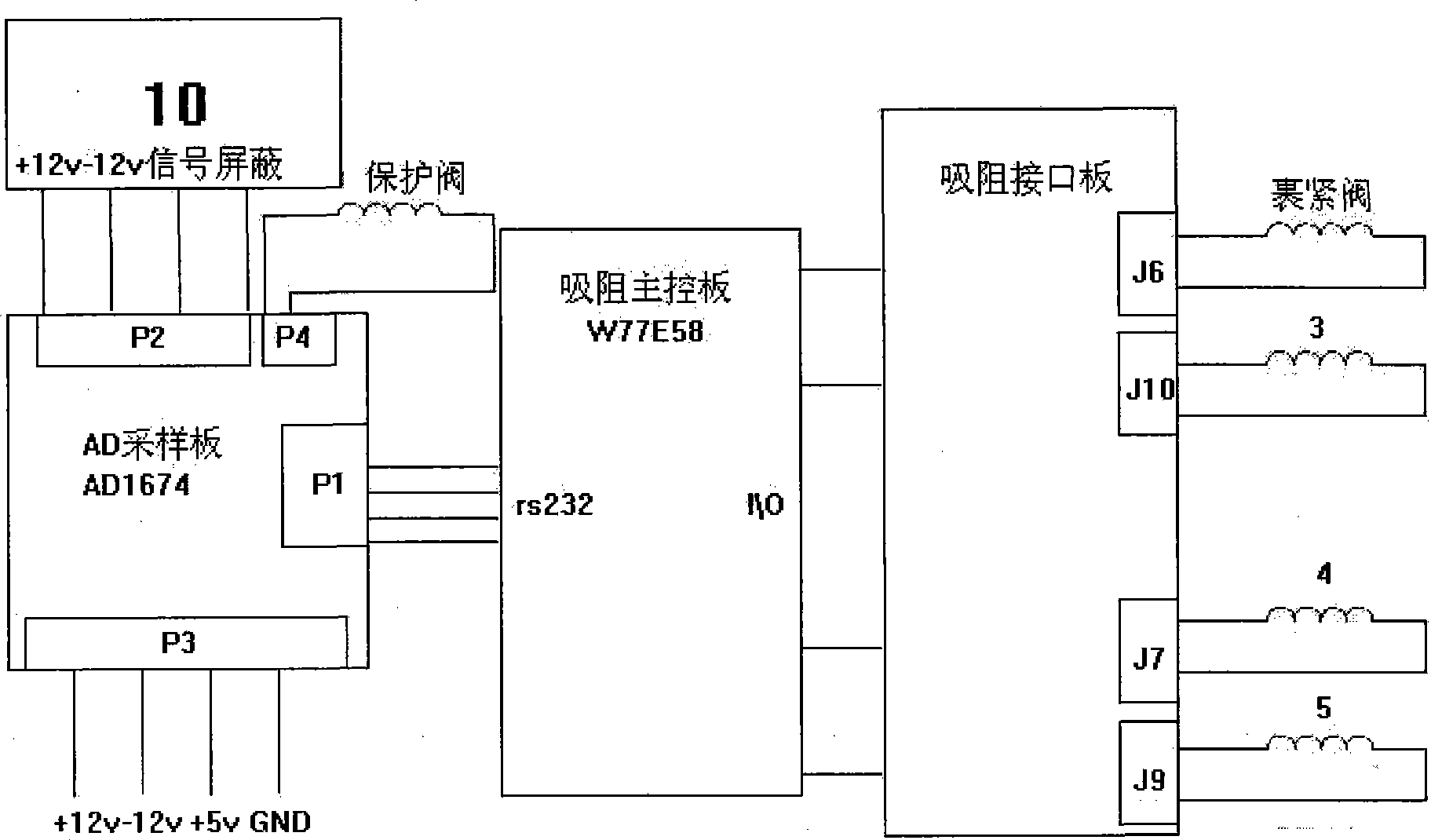

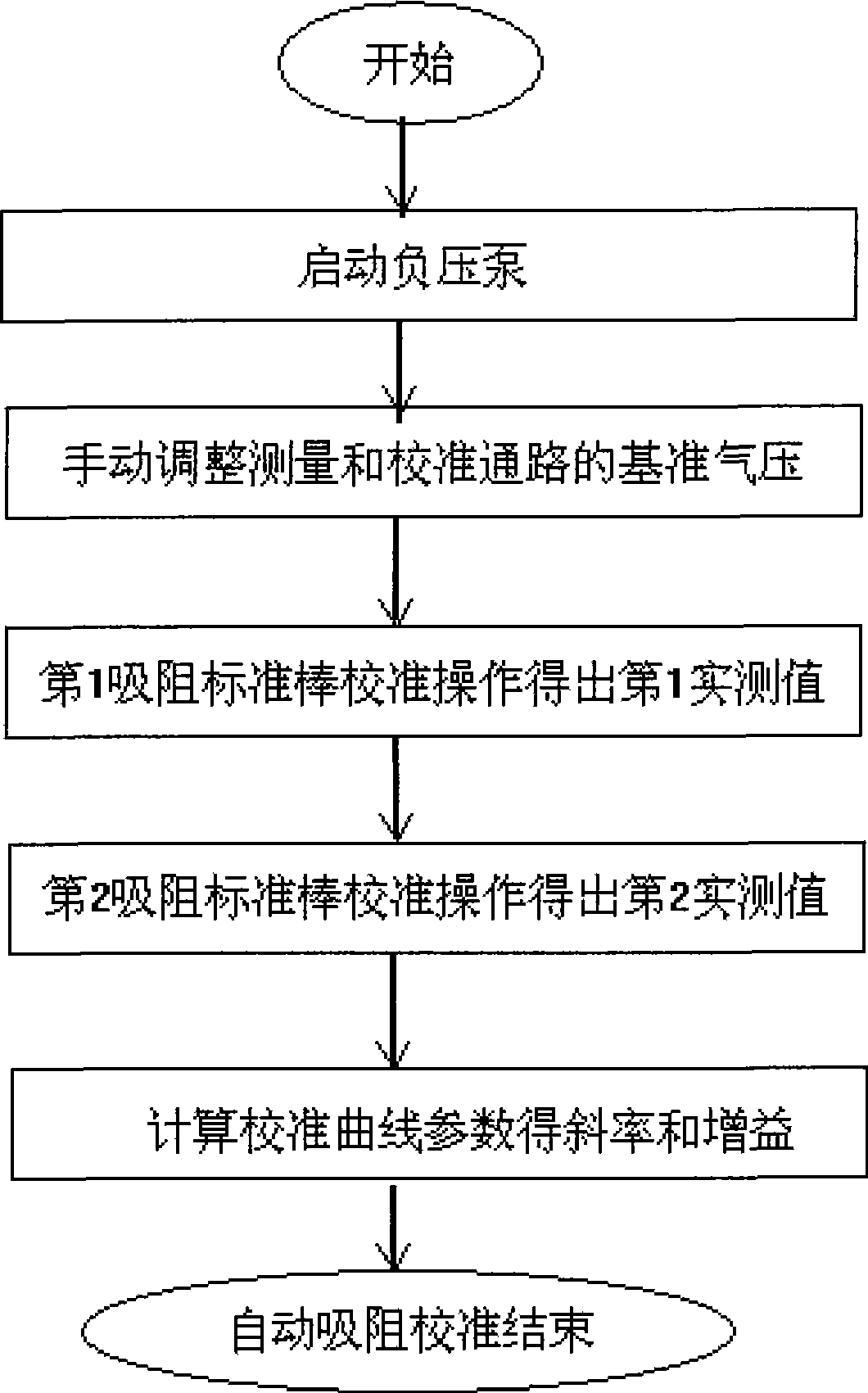

[0018] Such as figure 1 , 2 As shown, the automatic calibration system of the draw resistance meter of the present invention is set in the cigarette filter rod object detection test system, including the gas circuit device and the electric control device, the gas circuit device includes the calibration gas circuit and the measurement gas circuit, wherein the calibration gas circuit has a first , 2 suction resistance standard rod measuring heads 2a, 2b, the first standard rod measuring head 2a passes through the first electric valve 4 (this embodiment adopts a normally closed valve), the first manual regulating valve 7 and flow constant elements and buffers on the gas pipeline The chamber 9 is connected to the negative pressure vacuum pump 11; the second standard rod measuring head 2b passes through the second electric valve 5 (this embodiment adopts a normally closed valve), the second manual regulating valve 8 and the constant flow element and the buffer chamber 9 on the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com