Device and method for measuring object mass center

A measuring device and center-of-mass technology, which is applied in the direction of measuring device, measuring force, vehicle testing, etc., can solve problems such as inconvenient installation, inconvenient operation, and complex structure of mechanical devices, and achieve easy error, simple device structure, and quick operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

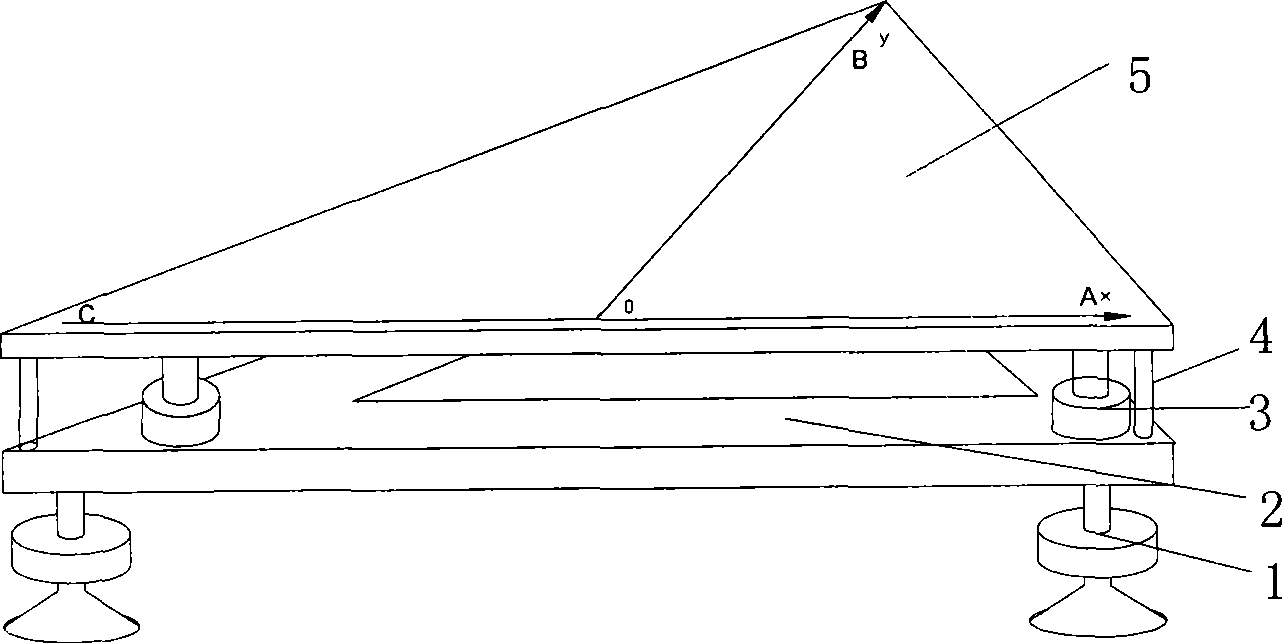

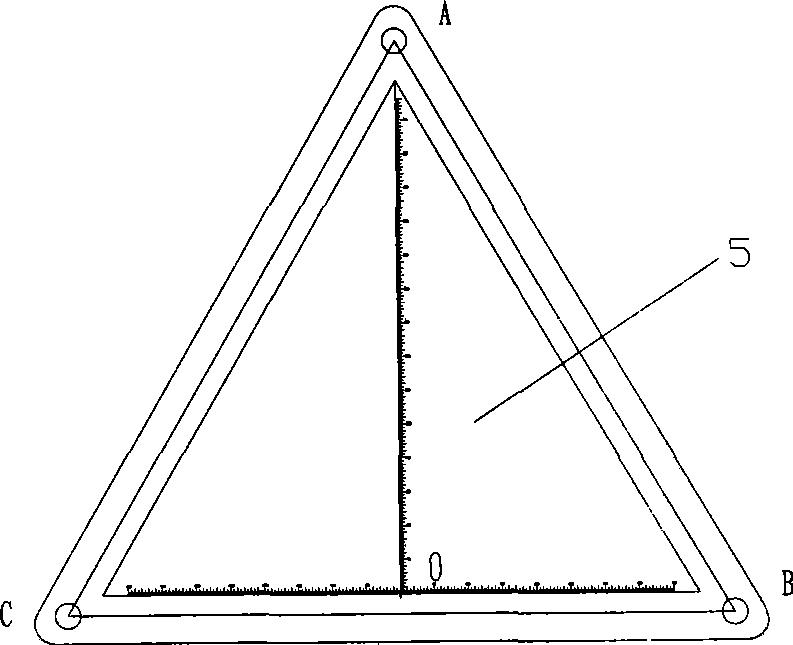

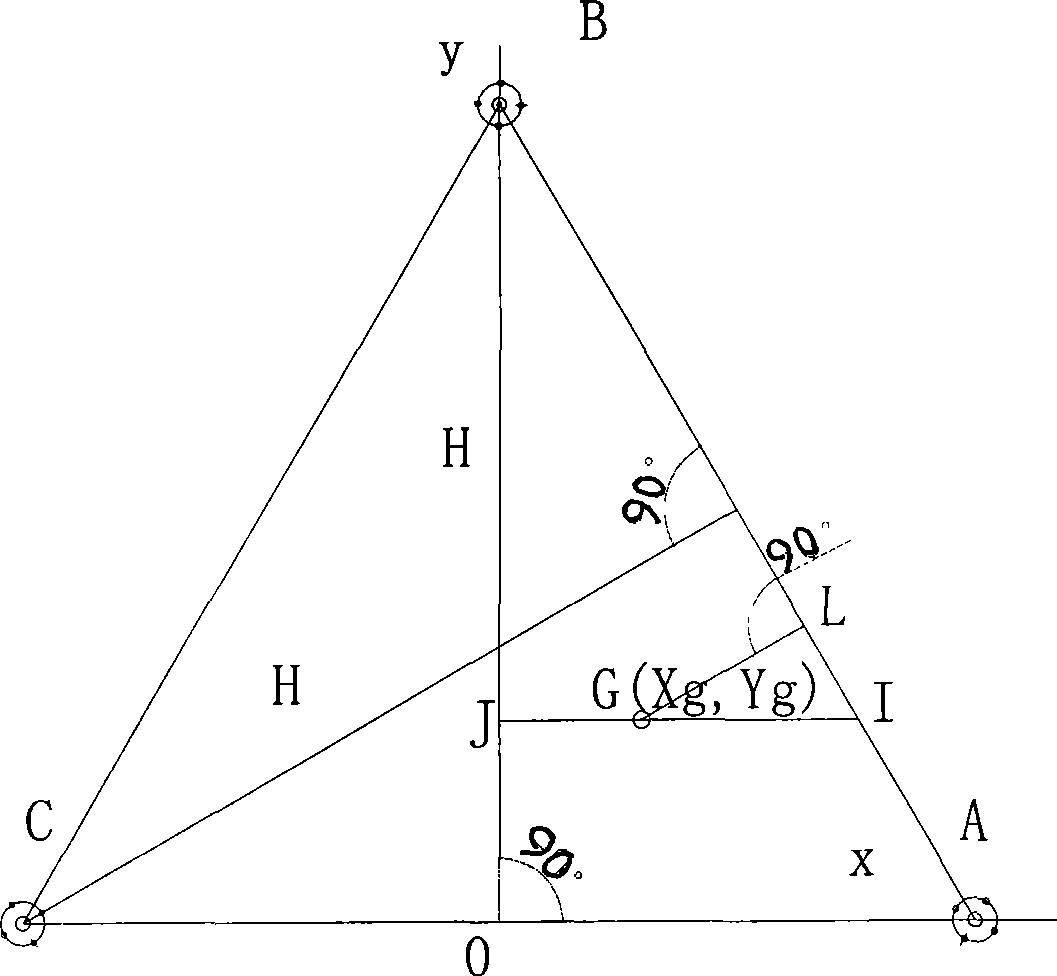

[0041] Example figure 1 , 2 As shown, a device for measuring the center of mass of an object is composed of three load cells 3, a measuring table 5, a triangular base 2, a height-adjustable support foot 1, and a computer. The three load cells are electrically connected to the computer. Three height-adjustable supporting feet 1 are respectively installed under the three corners of the triangular base 2, and three load cells 3 are installed on the three corners, and the three load cells are precisely positioned, and the position points are respectively A, B, C, distributed in an equilateral triangle; a measuring table is arranged on the three load cells, and the level of this table needs to be adjusted during measurement. A scale is engraved on the table to establish rectangular coordinates. The load cell achieves point contact with the horizontal surface for precise positioning. When installing the measured object, in order to protect the three force sensors from excessive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com