Apparatus for measuring plunger sub-oil film viscous friction

A measuring device and friction force technology, applied in the direction of measuring device, measuring fluid pressure, measuring fluid pressure through electromagnetic elements, etc., can solve the problem of failure to consider the mutual disturbance of the plunger distribution structure, etc., and achieve ingenious design and application, reliable performance. , the effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

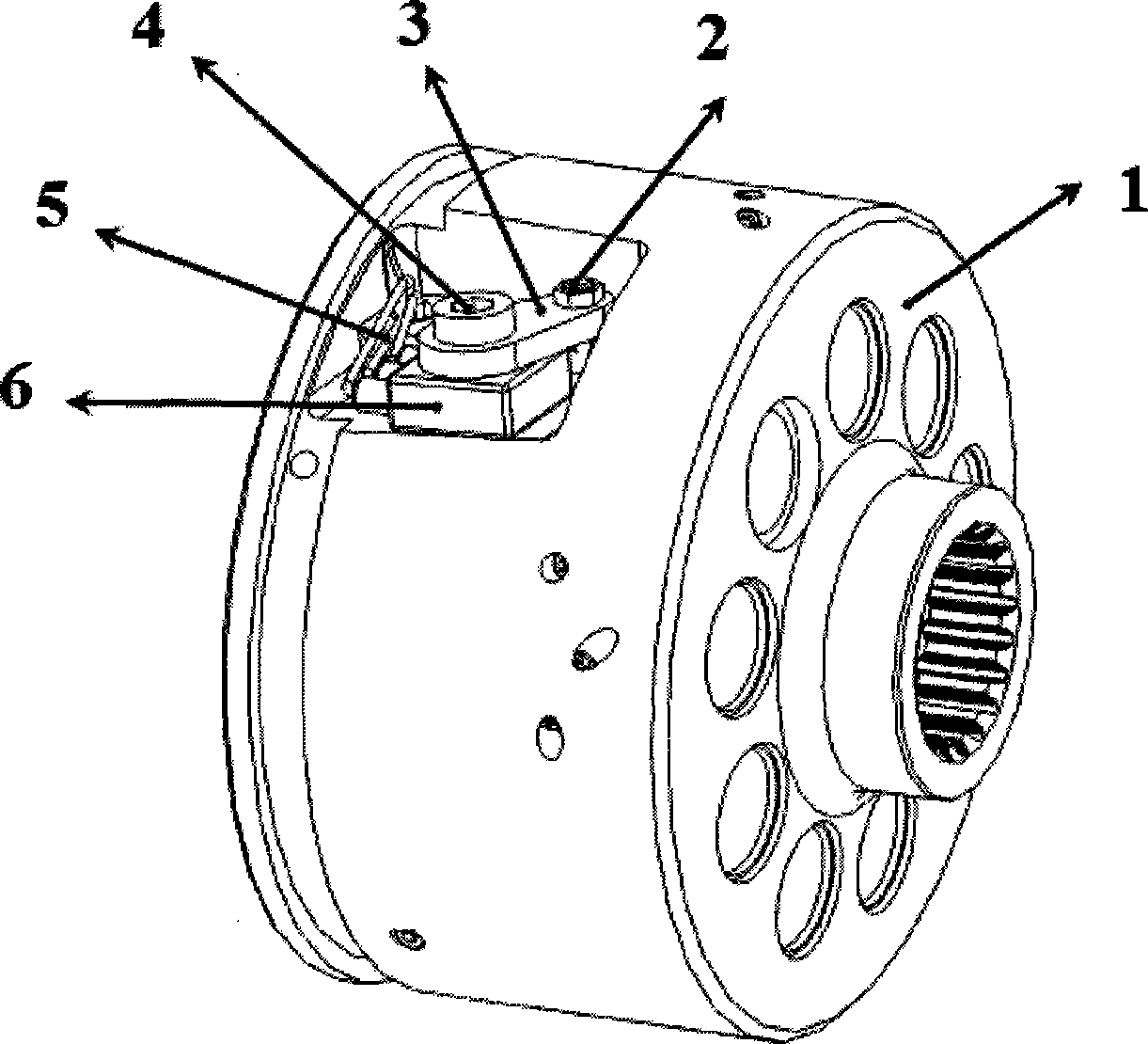

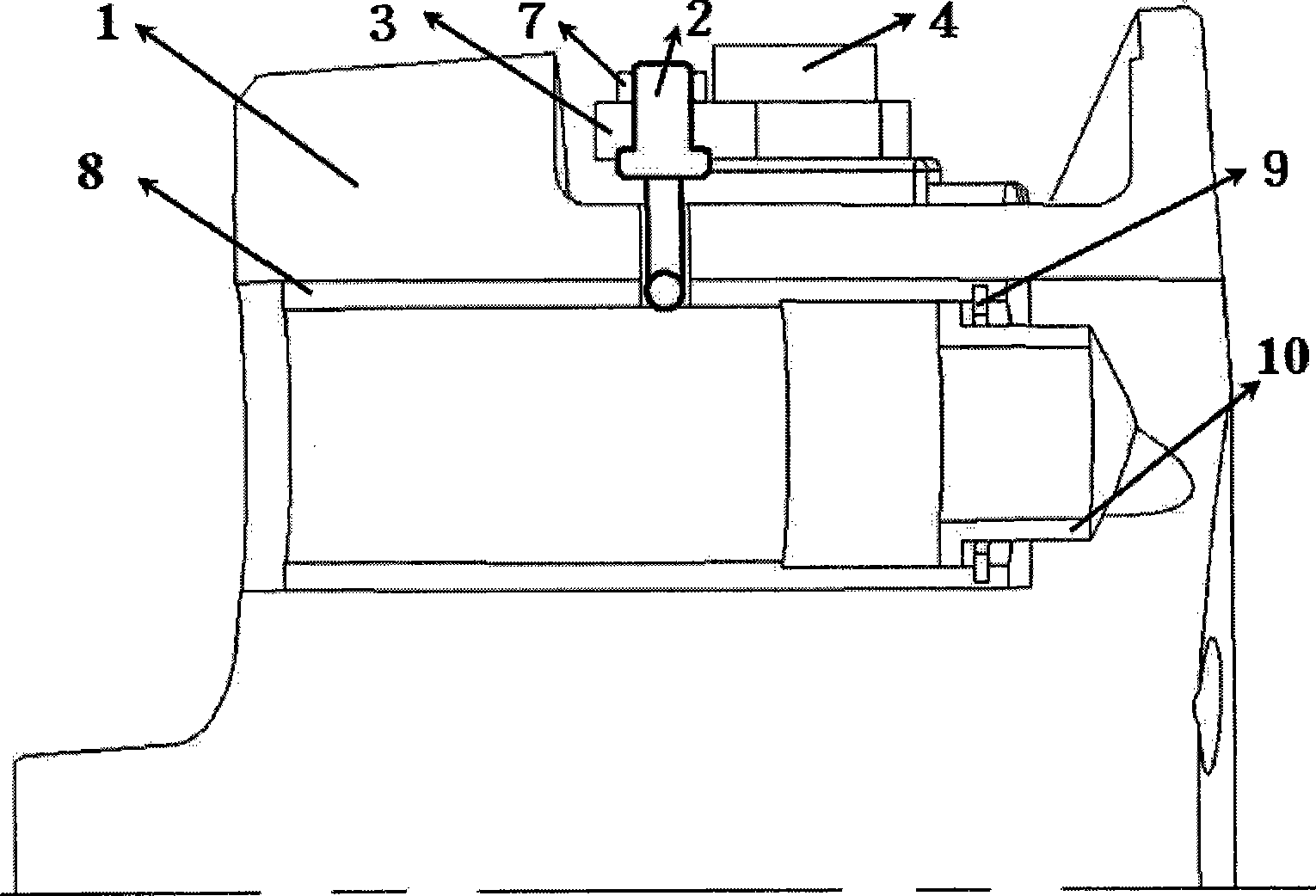

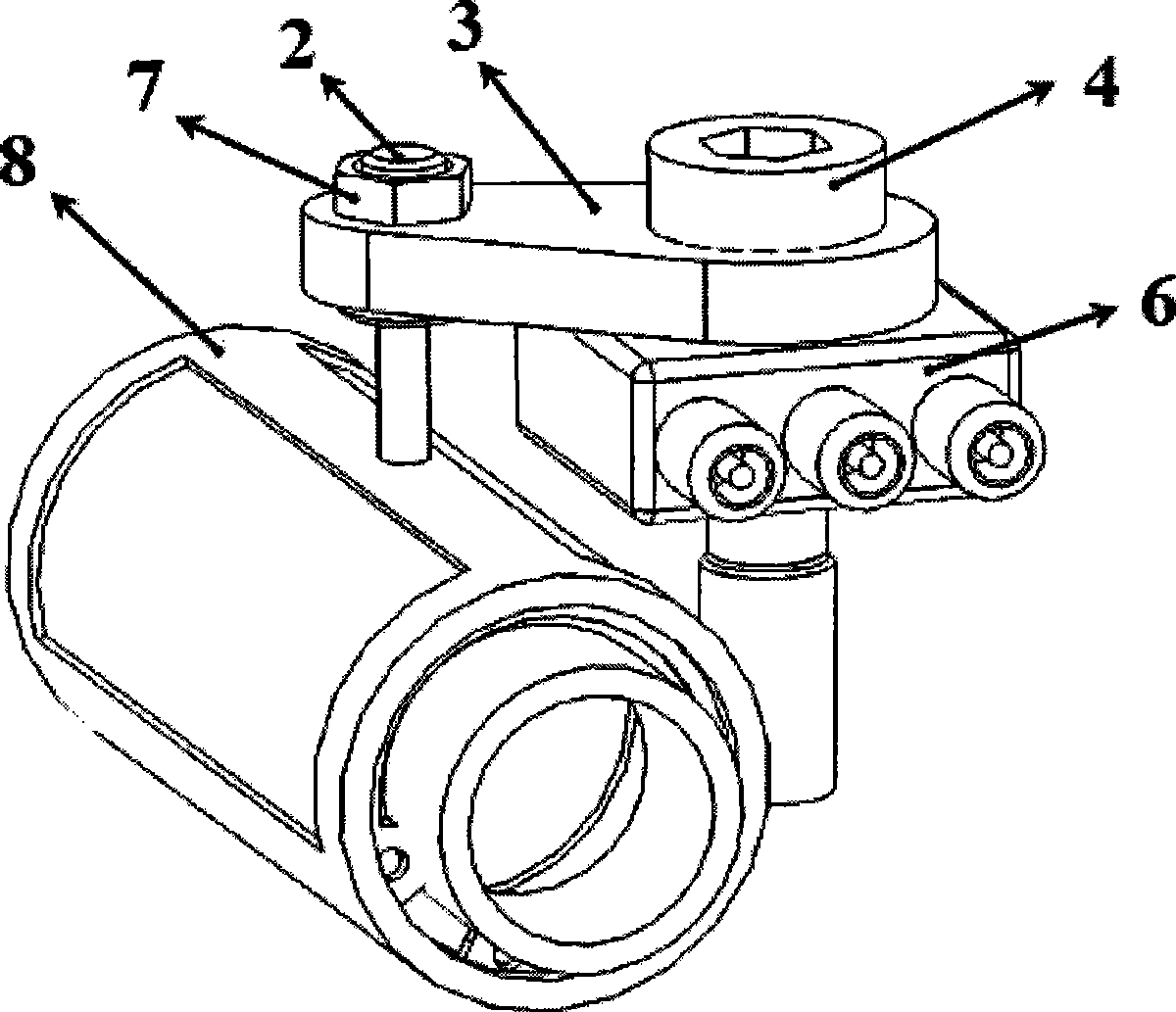

[0023] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a cylinder body 1, a sensing rod 2, a connecting rod 3, a fastening screw 4, a sensor cable 5, a friction sensor 6, a fixing nut 7, a plunger bushing 8, and a spring collar 9 , guide rod 10 and one-way valve 11; in the plunger chamber of cylinder 1, the guide rod 10 and plunger bushing 8 are connected together by spring collar 9 to form a floating bush supported by static pressure Assemblies, the guide rod 10 in the floating bush assembly is interference fit with the rear end of the plunger cavity, the plunger bushing 8 and the spring collar 9 can float relative to the guide rod 10, and the spring collar 9 and the guide rod 10 bosses are used to limit the floating maximum displacement mutually. Therefore, the floating plunger bushing 8 can be driven to float by the axial and radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com