Supporting type double-seal double-gate plate flat plate gate valve

A double-sealed, flat gate valve technology, applied in sliding valves, valve details, valve devices, etc., can solve the problems of large occupied space, reduced sealing performance, complex structure, etc., and achieve the effect of improving sealing performance and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

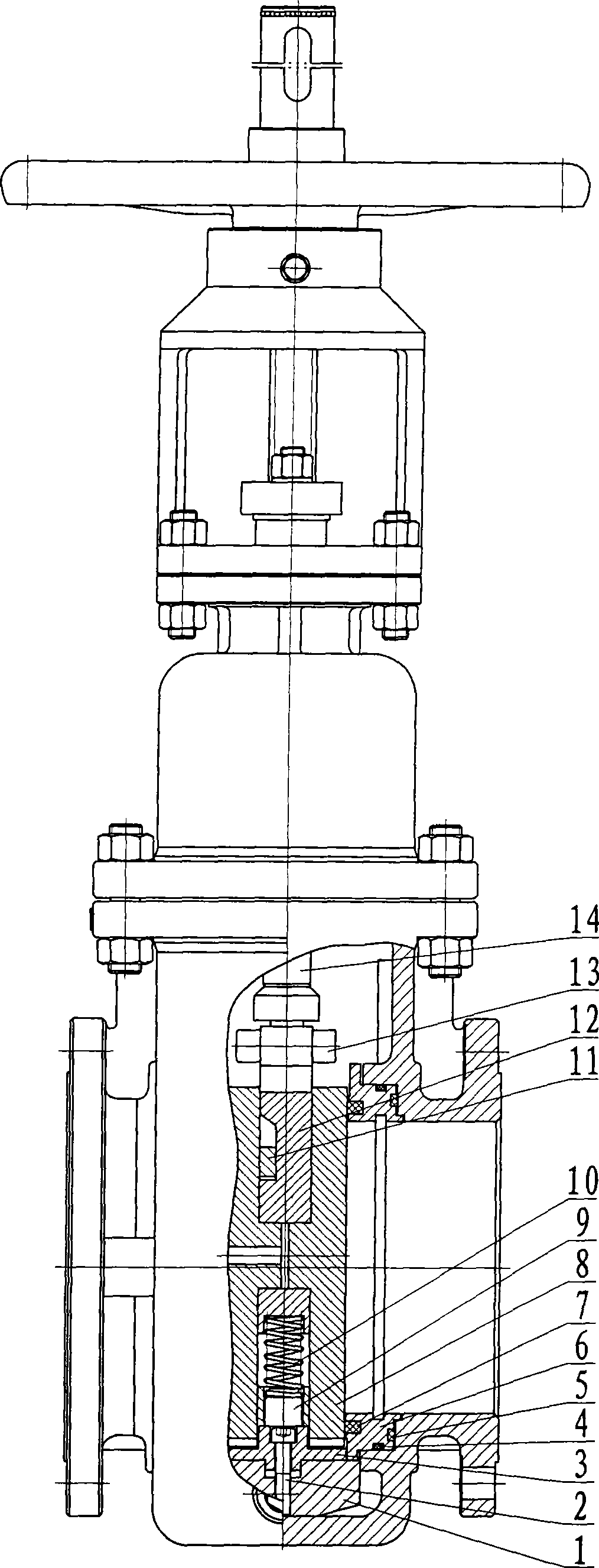

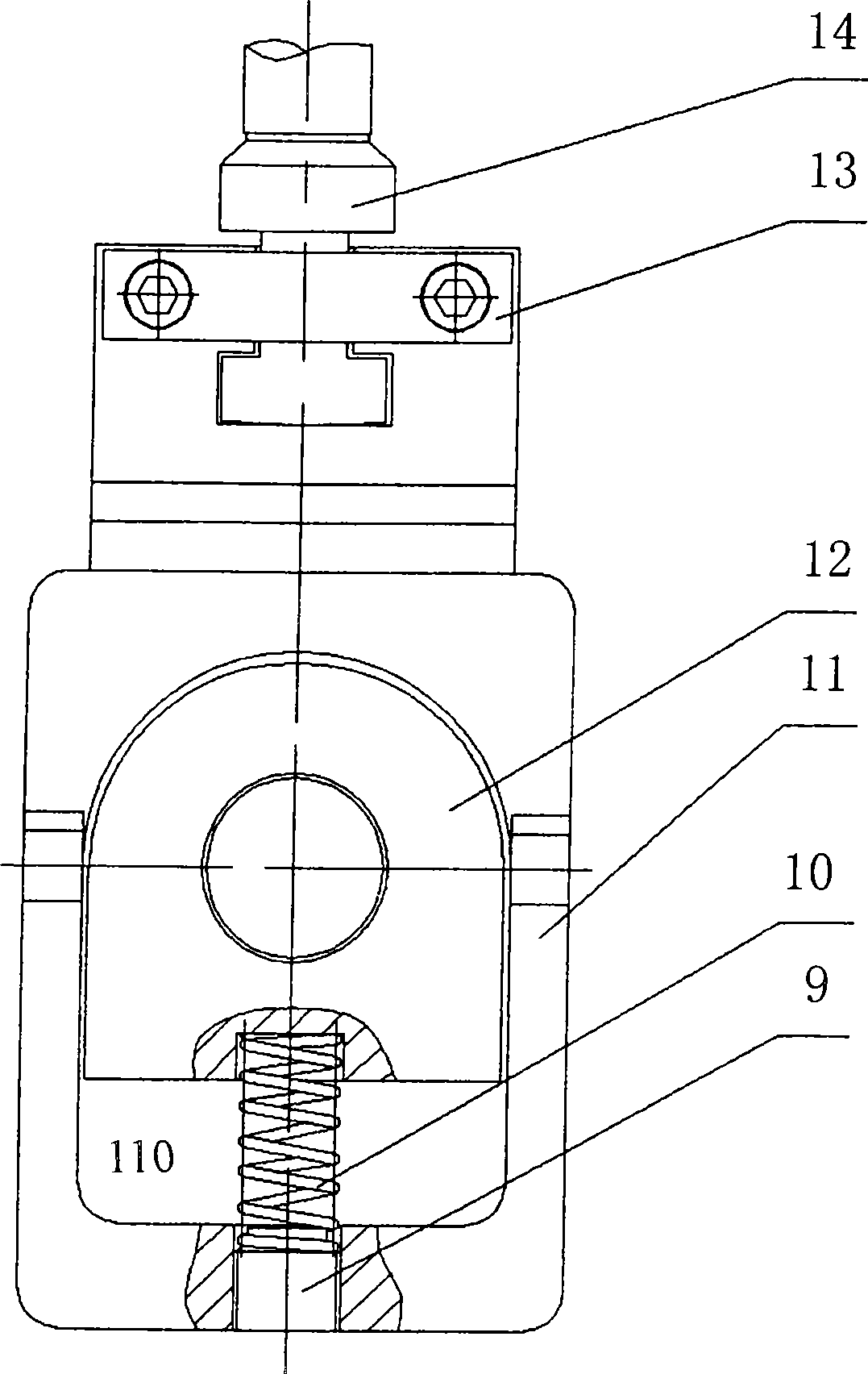

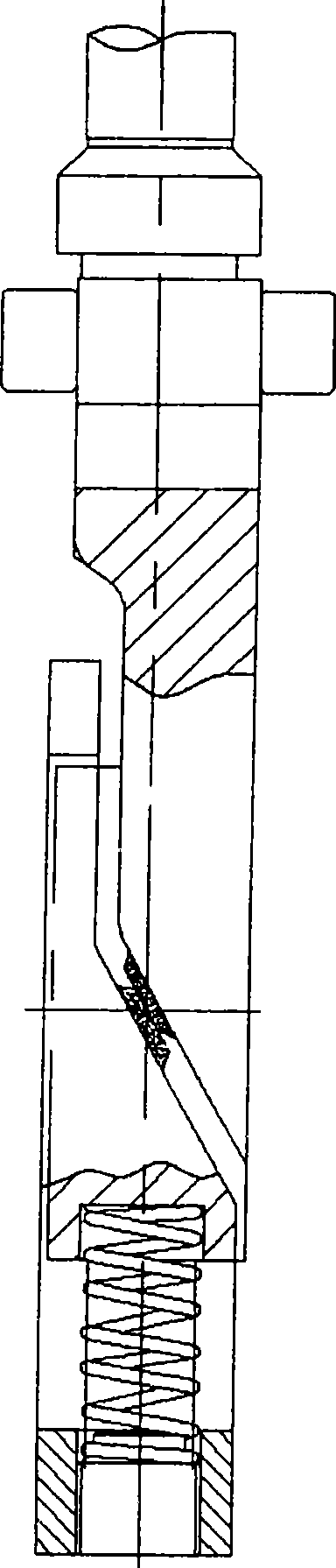

[0012] Such as figure 1 As shown, the expanded double-seal double-gate slab gate valve provided by the present invention includes a valve stem 14 whose lower end is fixedly connected to an upper wedge 12 , and a baffle 13 is also provided on the valve stem above the upper wedge 12 . The expansion mechanism on this gate (see figure 1 ) consists of two parallel flat gates 8, valve stem 14, upper wedge 12, compression spring 10, spring spacer 9, lower wedge 11, upper spacer 3, lower spacer 1, hexagon socket screw 2 and other parts composition. The upper wedge 12 is fixedly connected to the lower end of the valve stem 14, and the two flat gates 8 are fixedly installed in the horizontal hole provided in the middle part of the upper wedge 14, and the lower wedge 11 is set right under the upper wedge 12, The middle of this lower wedge 11 is provided with an upper wedge accommodating hole (see figure 2 ) 110, the upper wedge 12 is placed in the accommodation hole 110 of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com