Hydraulic claw bucket of slotting machine

A hydraulic grab and slotting machine technology, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of increasing the load capacity of the crane, increasing the cost of the crane, etc., to increase the weight, increase the excavation depth, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] best practice

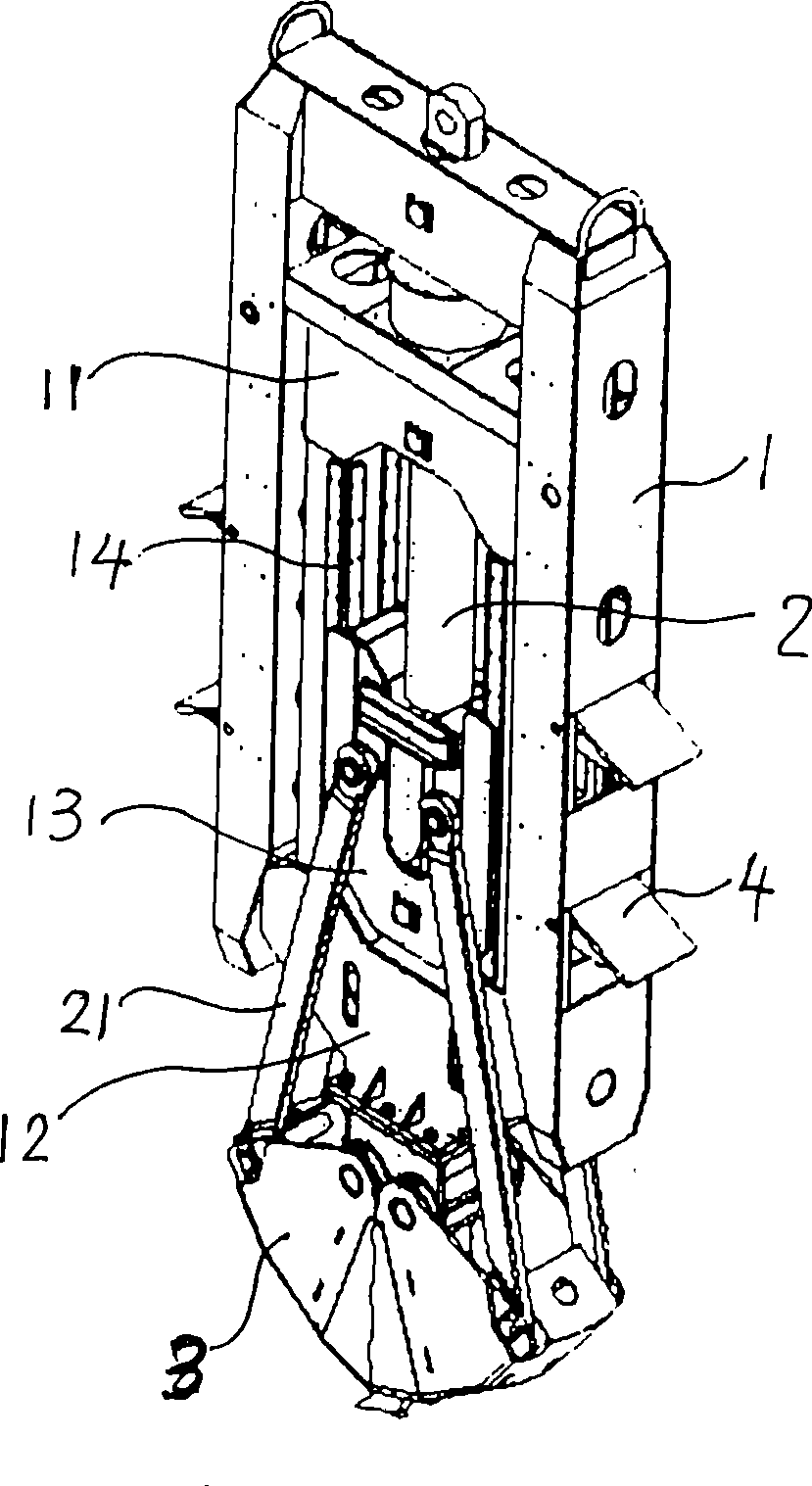

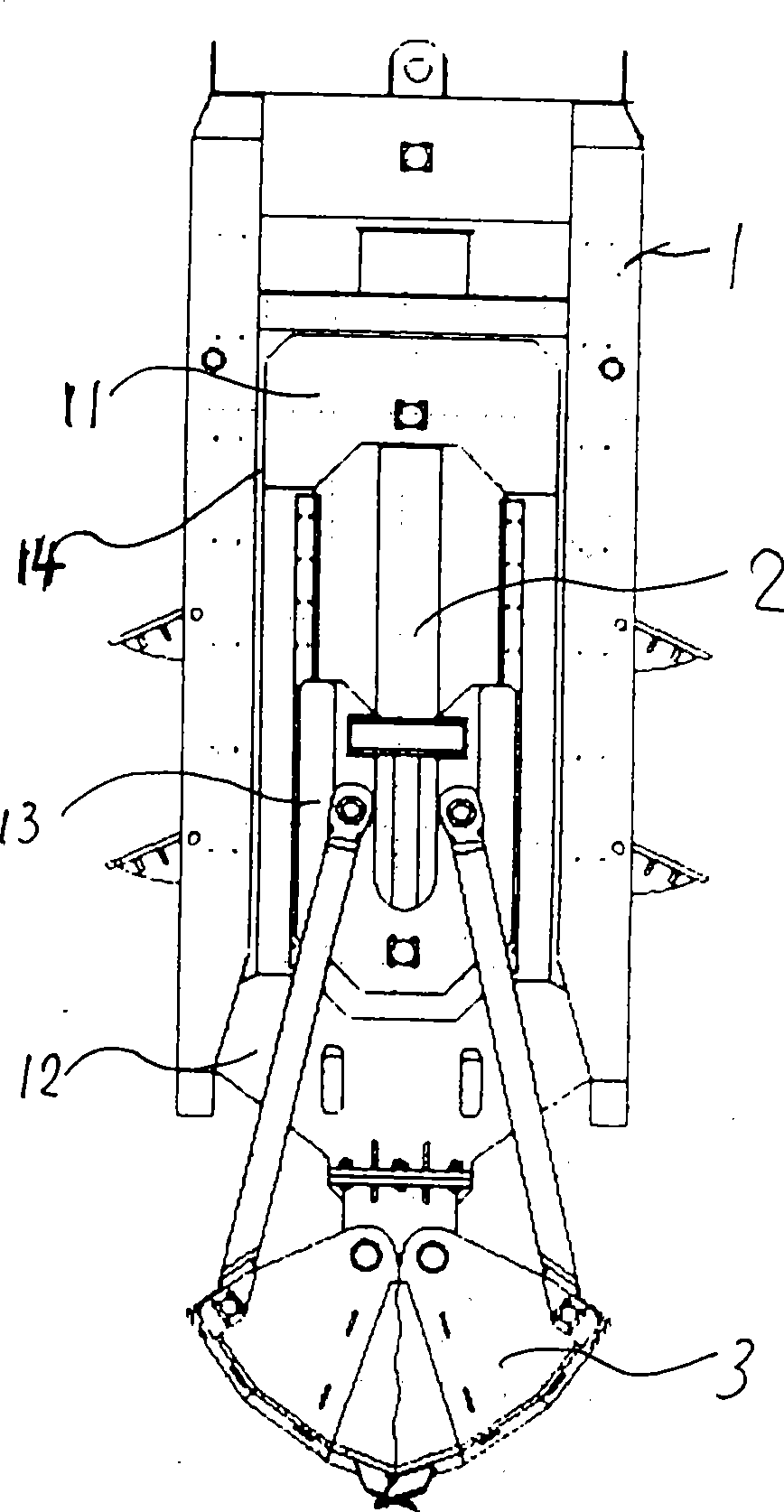

[0015] The present invention is an improvement to the hydraulic grab bucket of the existing slotting machine. One of the structures of the hydraulic grab bucket of the existing slotting machine is composed of a fuselage 1, a hydraulic device 2 and a grab bucket 3. The fuselage 1 is an upright giant frame structure, and its upper part is provided with a fixing seat 11 of a hydraulic device 2 . The top end of the piston rod 21 of the hydraulic device 2 is fixedly connected with the moving block 13 , and the moving block 13 is installed in the guide grooves 14 on both sides of the fuselage 1 . The lower end of the fuselage 1 is provided with a fixing seat 12 of the grab bucket 3 . The grab bucket 3 is affixed to the lower end of the fuselage 1 through the fixing seat 12 . The moving block 13 is movably connected with the grab bucket 3 through a connecting rod 15 .

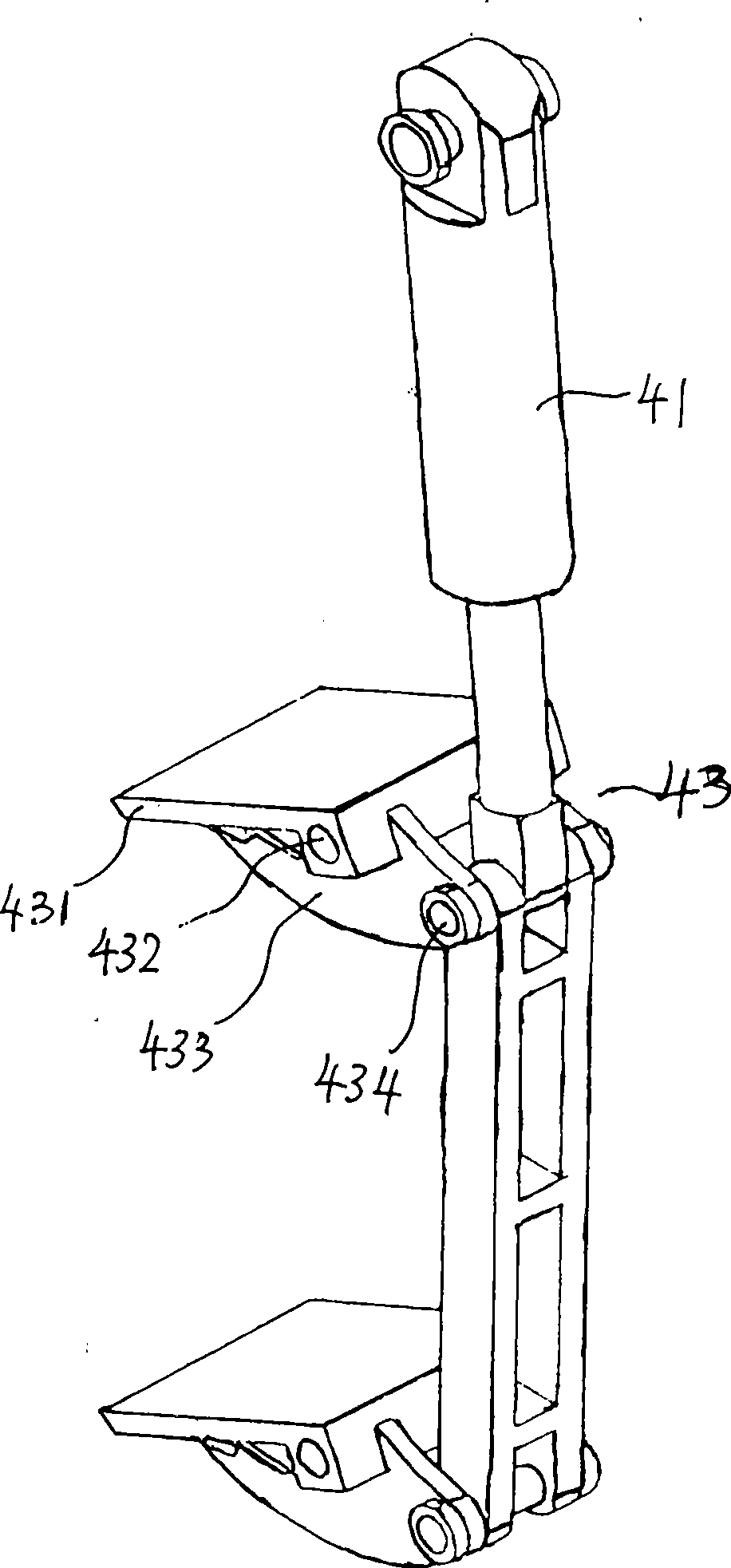

[0016] The present invention requires that the hydraulic grab can also have other structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com