Electric power plant circulating water rock plug type intake and construction method

A water intake and circulating water technology, which is applied in water conservancy projects, marine engineering, hydropower generation, etc., can solve the problems such as the outage of the first and second phase units, affecting the operation efficiency of the circulating water system, and the hidden danger of blasting impact force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

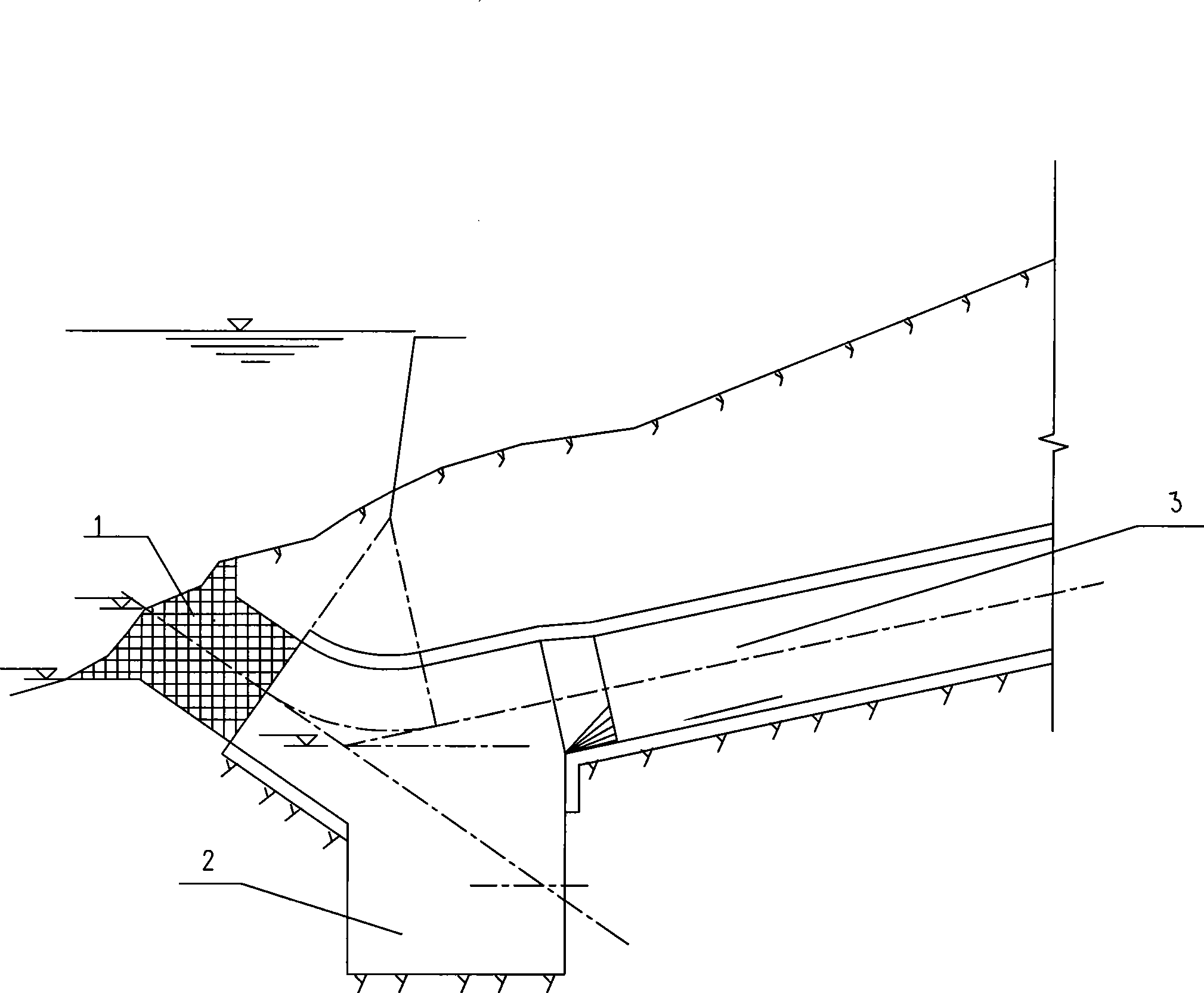

[0013] The present invention will be described in detail below in conjunction with accompanying drawing and example: figure 1 As shown, the rock plug type water intake of the present invention is arranged near the deep pool, and mainly consists of a rock plug 1, a ballast collection pit 2 and a water diversion tunnel 3 behind. The water diversion tunnel 3 is arranged in the mountain body and is inclined downward near the axis of the inlet section so that the axis of the rock plug water intake maintains an upward inclination of 35° to 60°. A sinking type ballast collection pit 2 is built between the diversion tunnel 3 and the rock plug 1 .

[0014] The cross section of the diversion tunnel 3 and the rock plug 1 is circular or quasi-circular or square or rectangular, figure 1 Shown is circular; the rock plug described has a thickness-to-diameter ratio of 1.13.

[0015] The construction method of the present invention is: the excavation construction of the water diversion tunne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com