Steel plate fixing device and method for pasting steel plate construction by coating and scraping method

A technology for pasting steel plates and fixing devices. It is applied in bridge reinforcement, bridge erection/assembly, bridge maintenance, etc. It can solve problems such as congestion and traffic inconvenience, and achieve the effect of speeding up construction progress, reducing impact, and improving social and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

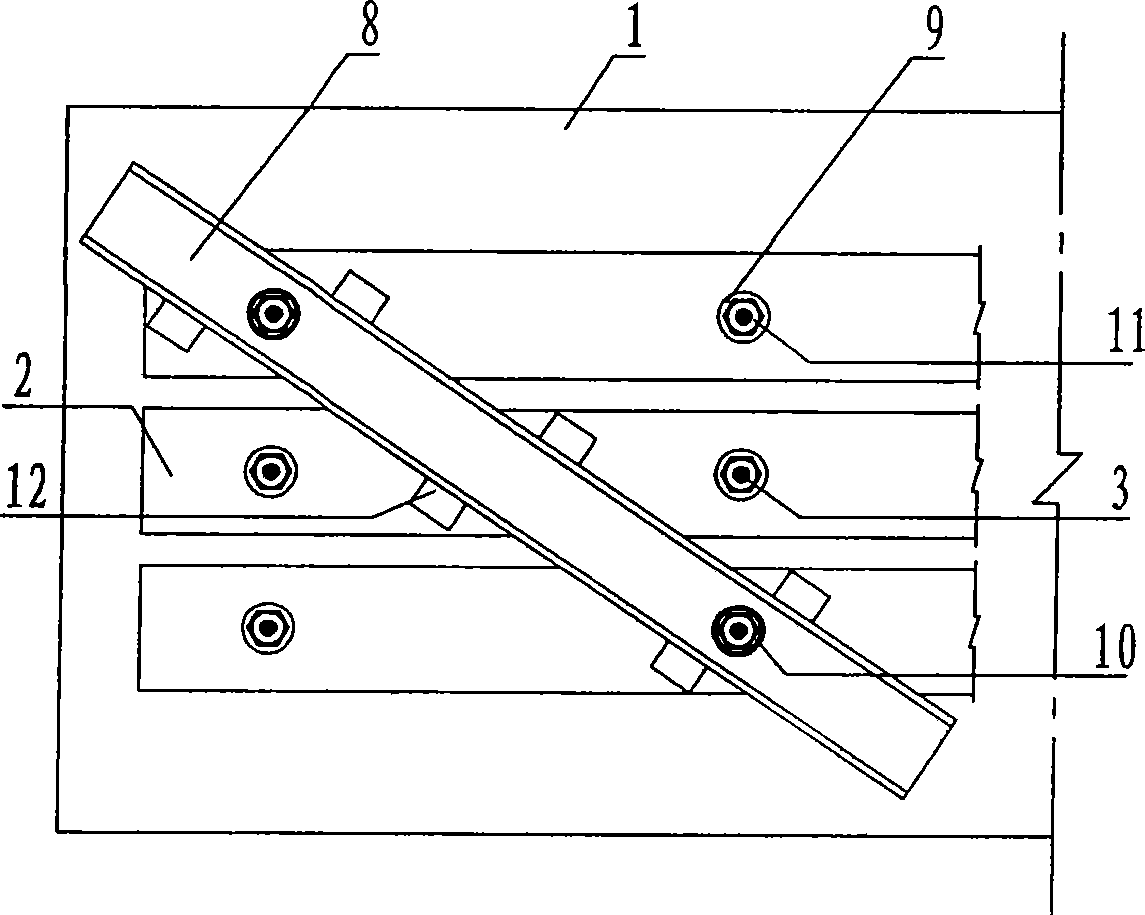

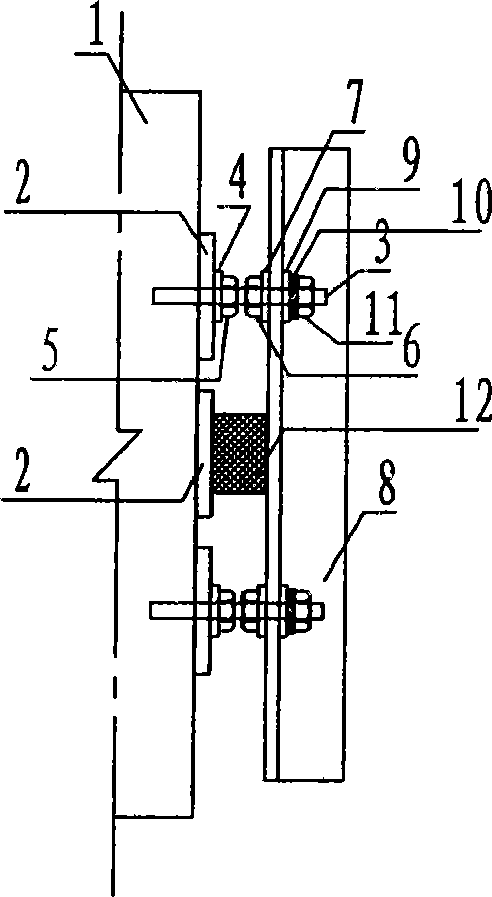

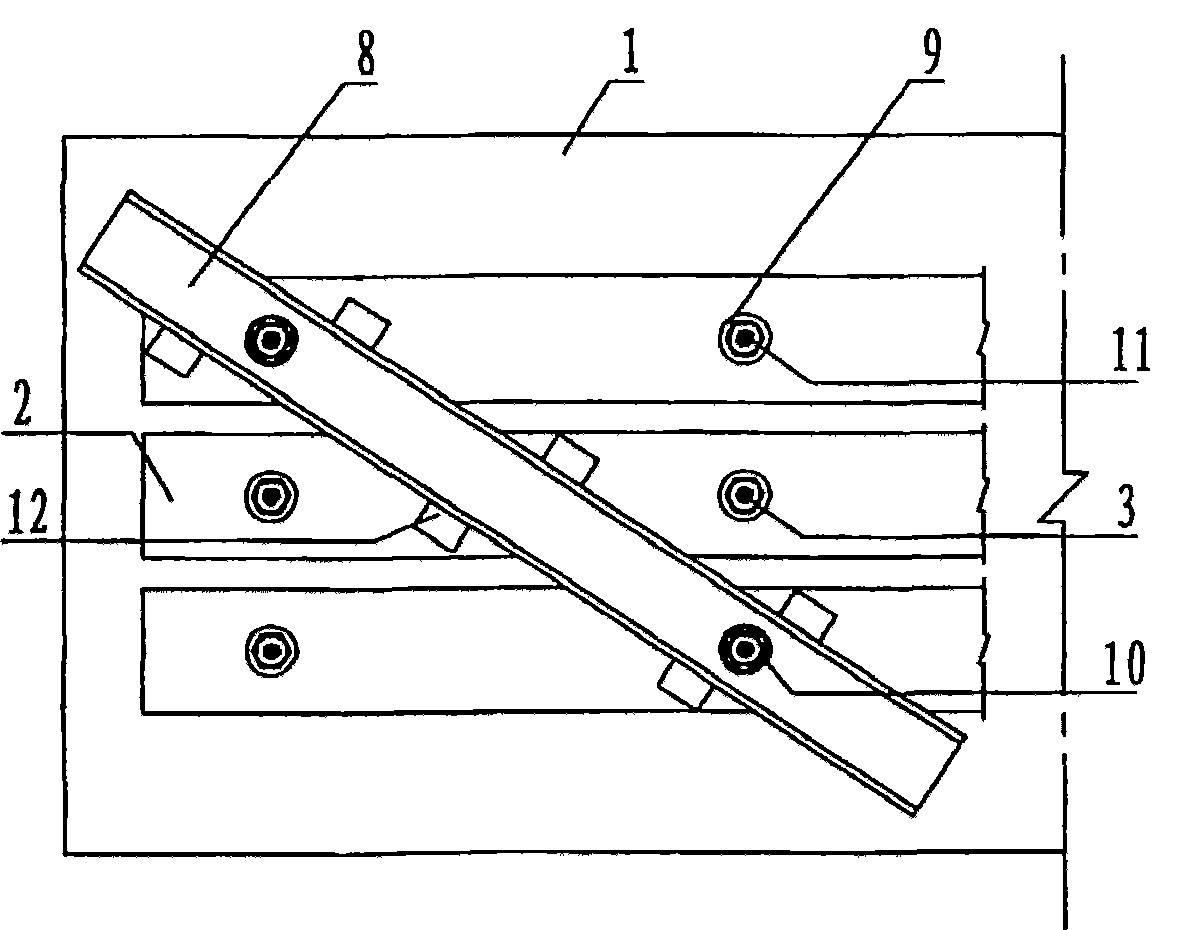

[0011] refer to figure 1 , 2 , the fixing device of the present invention, the steel plate 2 has the hole that passes through the anti-degumming bolt 3 on the reinforcement member 1, and the anti-degumming bolt 3 has a steel plate 2, an anti-degumming washer 4, an anti-degumming nut 5, and a lower nut 6 in sequence , lower gasket 7, shaped steel, channel steel or angle steel 8 and upper washer 9, elastic washer 10, upper nut 11, wooden wedge block 12 is arranged between steel plate 2 and shaped steel, channel steel or angle steel 8.

[0012] The method of fixing the steel plate fixing device for pasting the steel plate by coating and scraping method is to clean the surface of the reinforced member 1, implant anti-degumming bolts 3 into the reinforced member 1, clean and polish the steel plate 2, and apply scraping and sticking steel structure glue on the lower surface of the steel plate 2 After installing the steel plate 2 to the predetermined position on the reinforced membe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com