Non-contacting intelligent electric throttle

A non-contact, electronic throttle technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of poor environmental adaptability, wear and tear of resistors, and low service life, and achieve high reliability and increase Drivability and workload reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

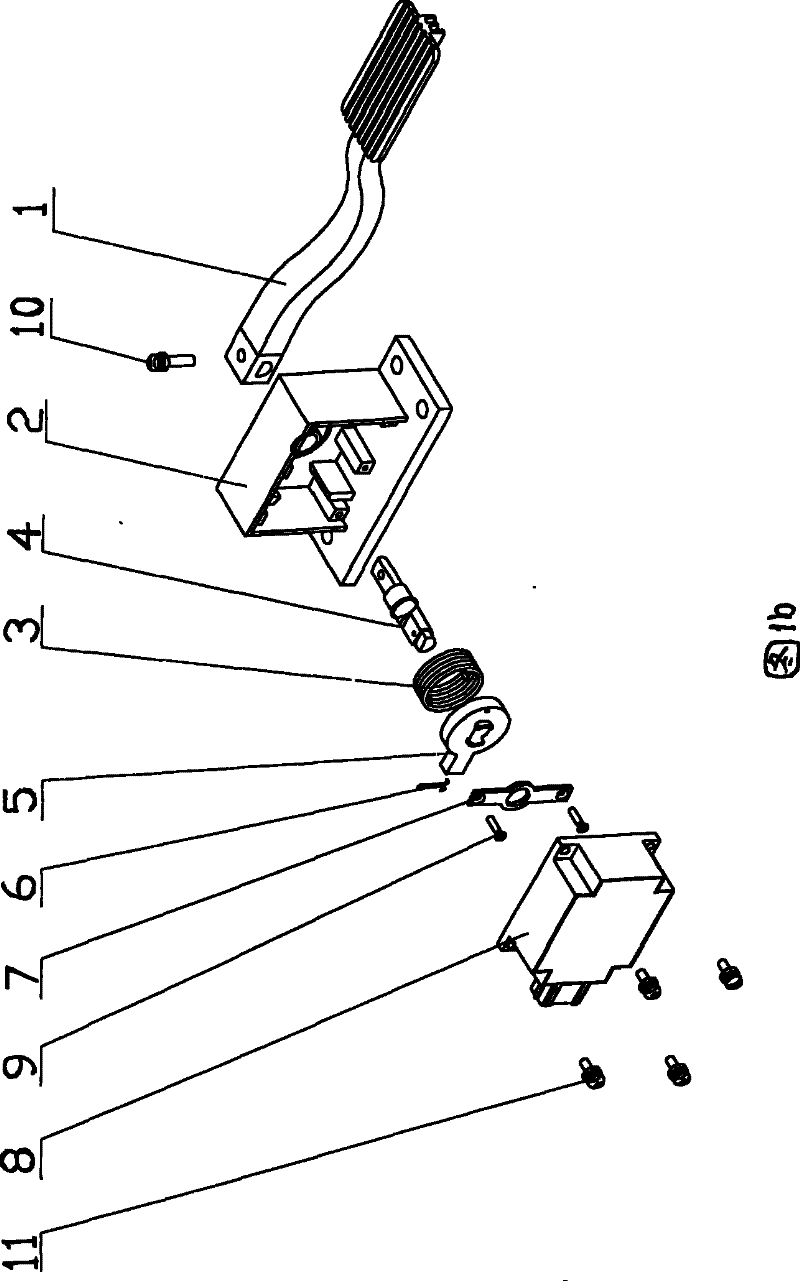

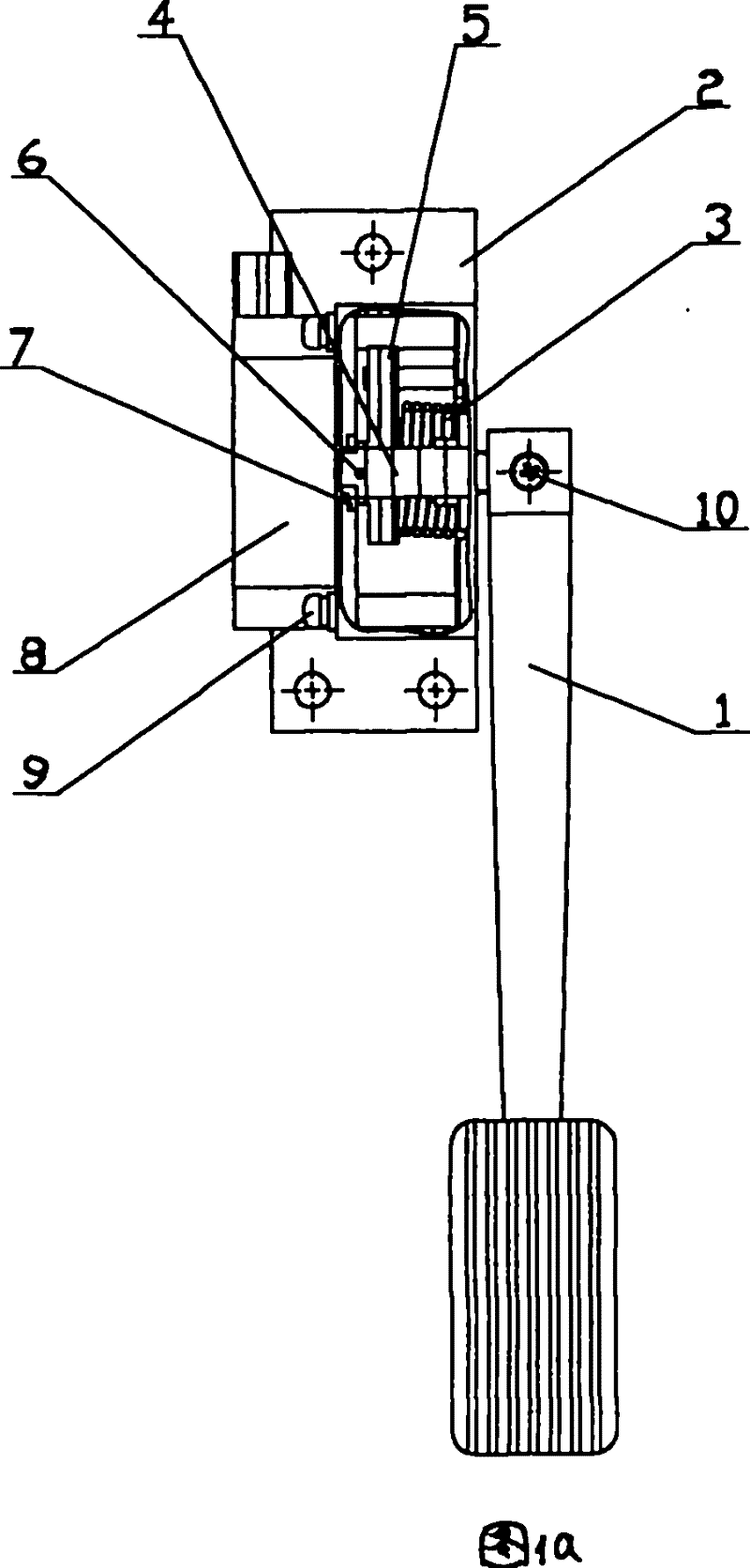

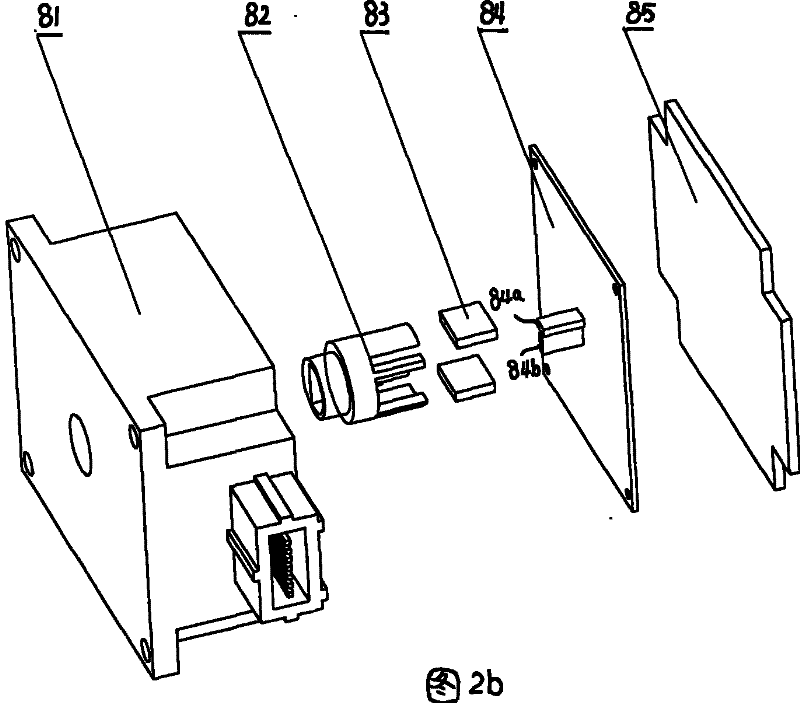

[0031] like Figure 1a , 1b As shown, the pedal 1, the return spring 3, the central shaft 4, the limit plate 5, the spring clip 6, the pressure plate 7, the sensor 8, the screw 9, the screw 10, and the screw 11 are all installed on the main supporting body 2. In Fig. 2, the structure of the sensor 8 is as follows: the sensor shaft 82 is arranged on the body 81, and two magnets 83 are fixed on the shaft, and the two-way linear Hall sensors 84a, 84b at a position of 90° are fixed on the circuit board 84 Above, the circuit board is fixed on the body 81, and the Hall sensors 84a, 84b are located within the uniform magnetic field generated by the two magnets 83, the strength of the magnetic field is less than the saturation strength of the Hall sensor; there is also a sensor shaft 82 controlled by the pedal 1 Driving mechanism: the pressure plate 7 is installed on the main support body 2, the central axis 4 is erected on the limit gap of the main support body 2 and the opening of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com