Cooling structure for working vehicle

A cooling structure and vehicle technology, which is applied to the cooling of the engine, the combined arrangement of the cooling of the power plant, and vehicle components, etc., and can solve problems such as increased noise, reduced heat dissipation, and increased operating speed of the air-cooling fan F

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, the present invention will be described in detail based on drawings showing embodiments.

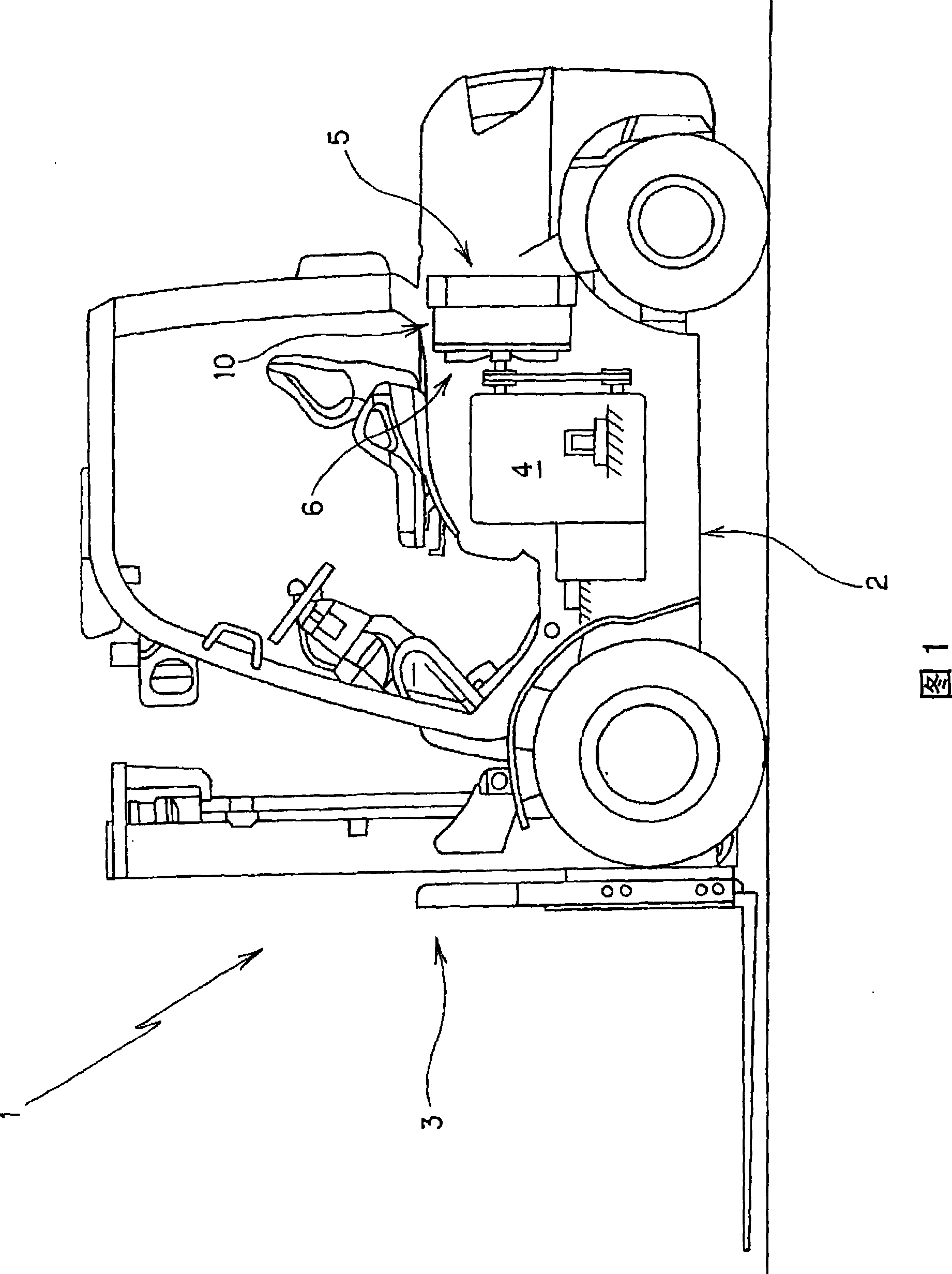

[0054] Figure 1 and figure 2 This is an example in which the present invention is applied to a fork-lift truck, which is one type of working vehicle, and the fork-lift truck 1 includes a vehicle body 2 and a working machine 3 installed in front of the vehicle body 2 .

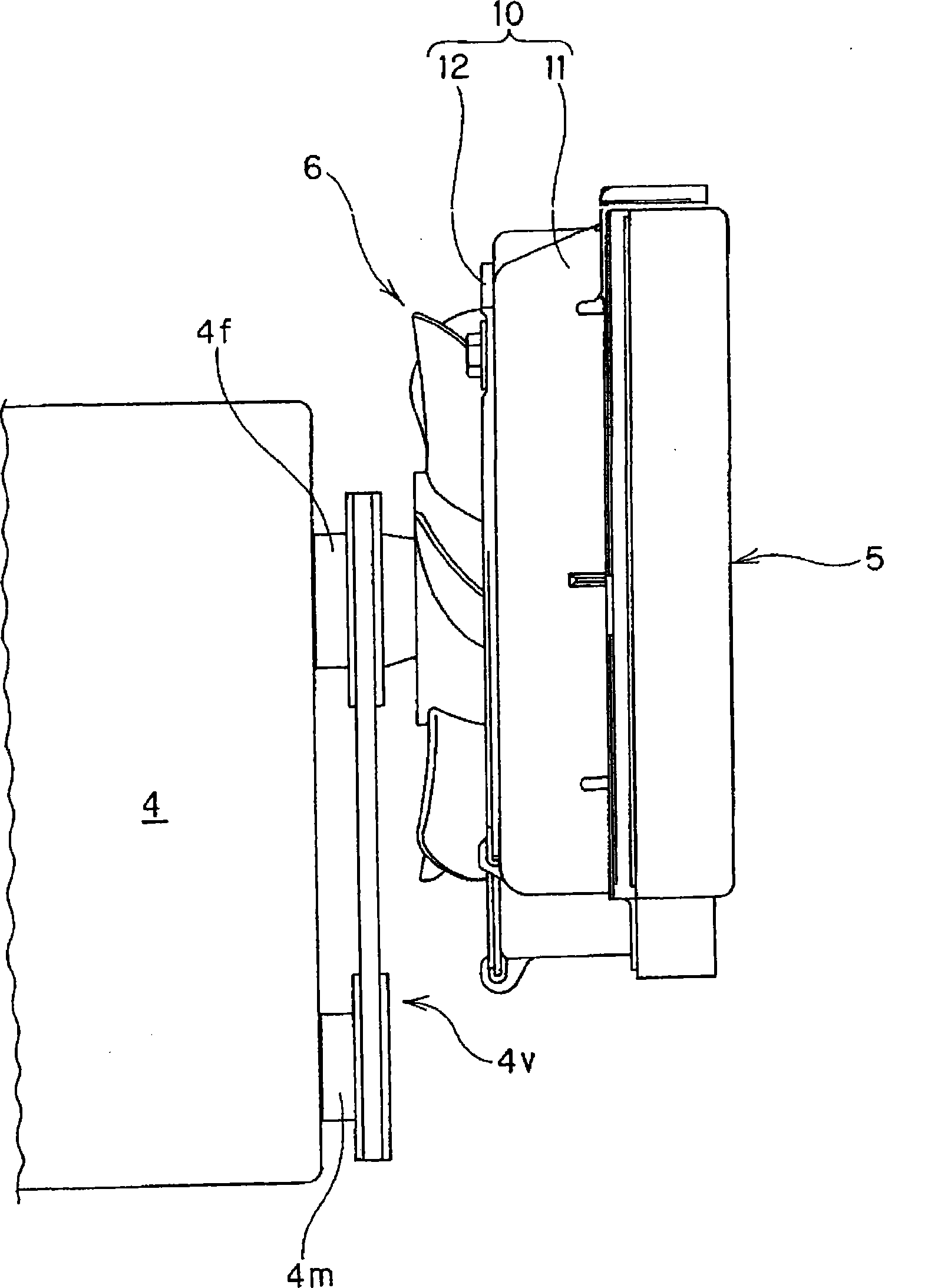

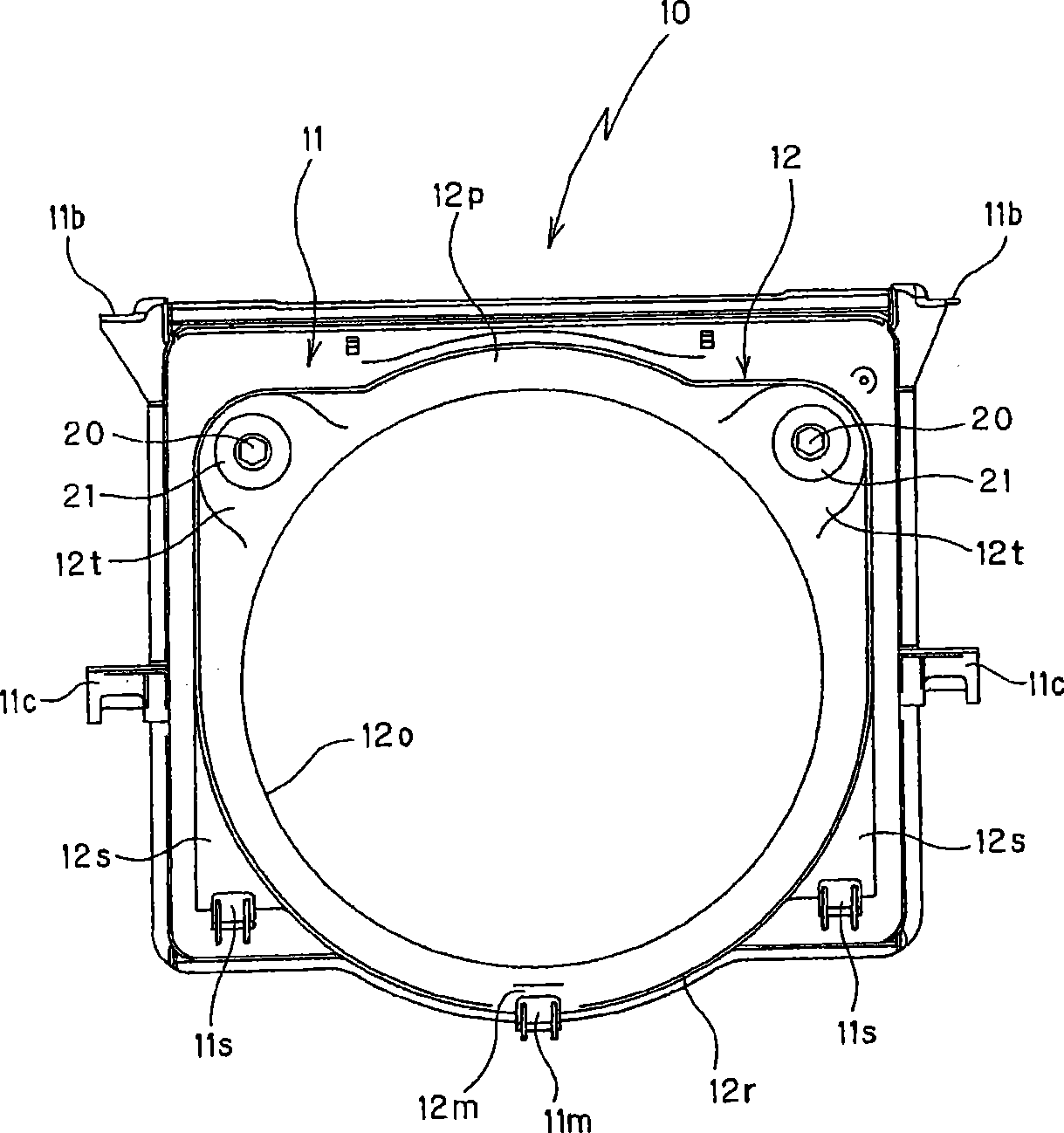

[0055]An engine 4 and a radiator 5 are mounted inside the vehicle body 2. The engine 4 is floatingly supported in the approximate central region of the vehicle body 2 via vibration-proof members such as rubber brackets. Describe the rear area of the engine 4.

[0056] The air-cooling fan 6 is rotatably supported at the rear of the engine 4 via a fan shaft 4f, and the fan shaft 4f is connected to the main drive shaft (output shaft) 4m via a transmission mechanism 4v, whereby the air-cooling fan 6 follows Rotation is driven by the operation of the engine 4 .

[0057] In the front area relative to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com