Parallel type honeycomb material power absorber

A technology of honeycomb materials and energy absorbers, which is applied in the field of energy absorbers, can solve the problems of low energy absorption efficiency, unfavorable energy absorber lightweight and compact design, etc., and achieve the effect of improving load fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

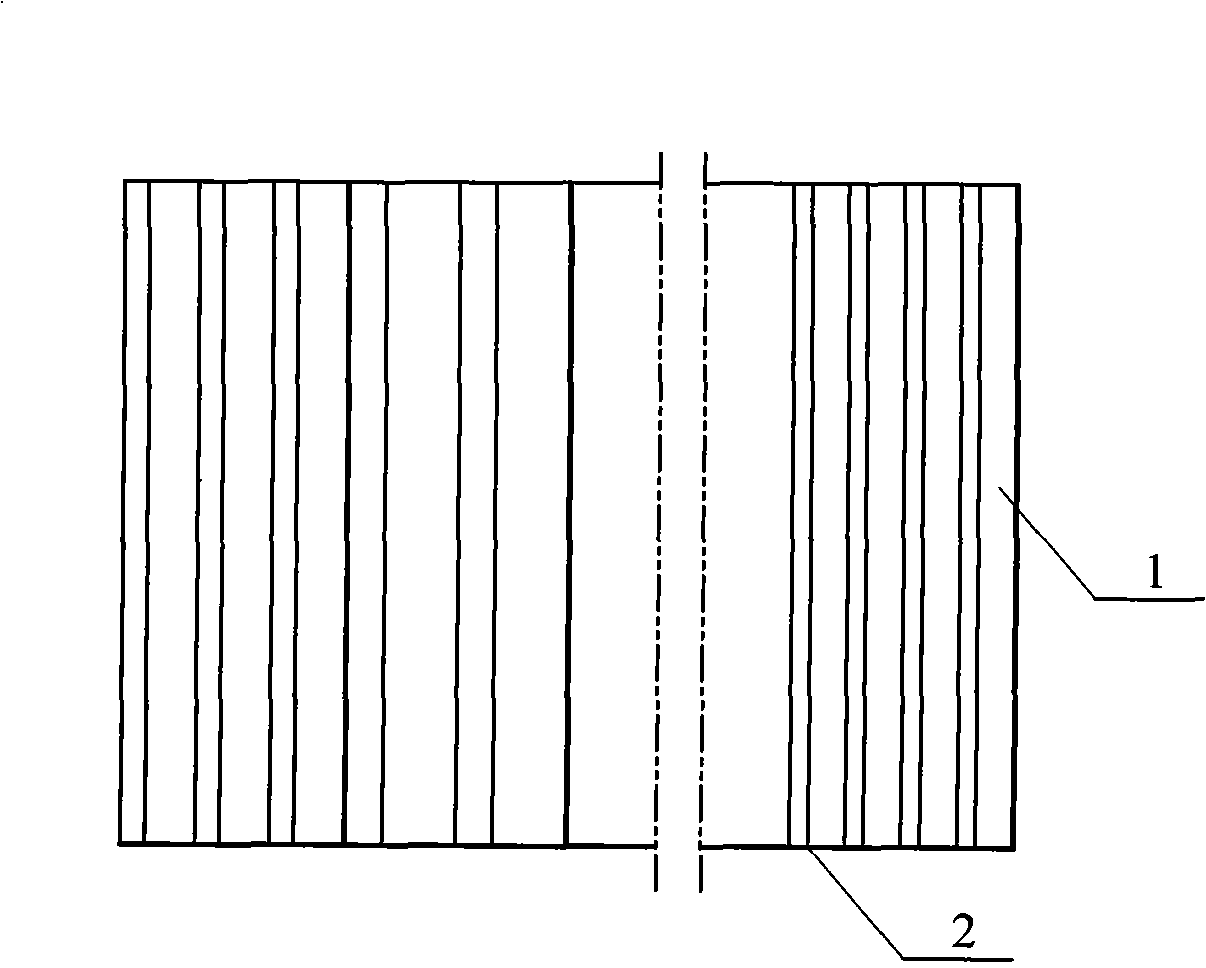

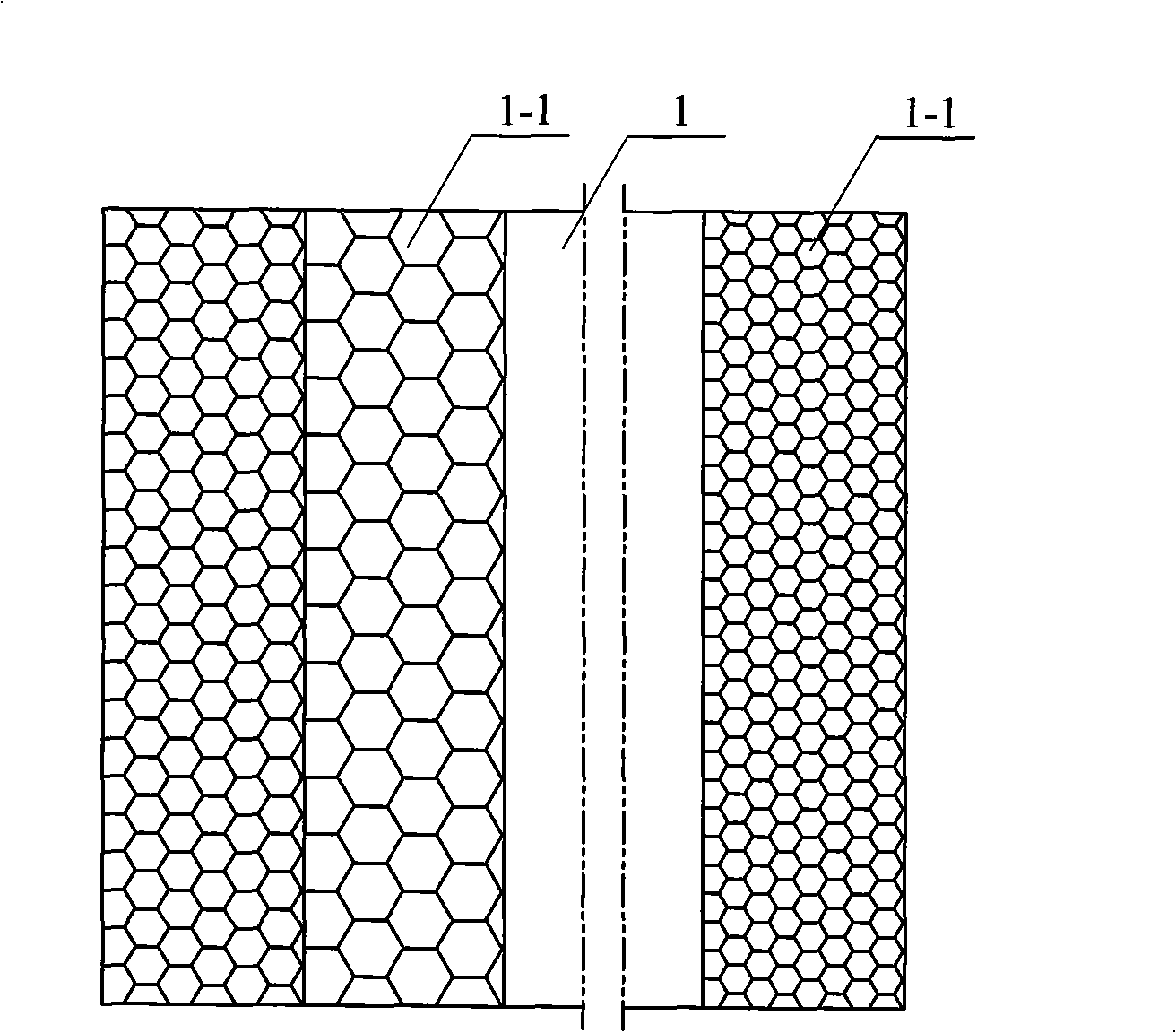

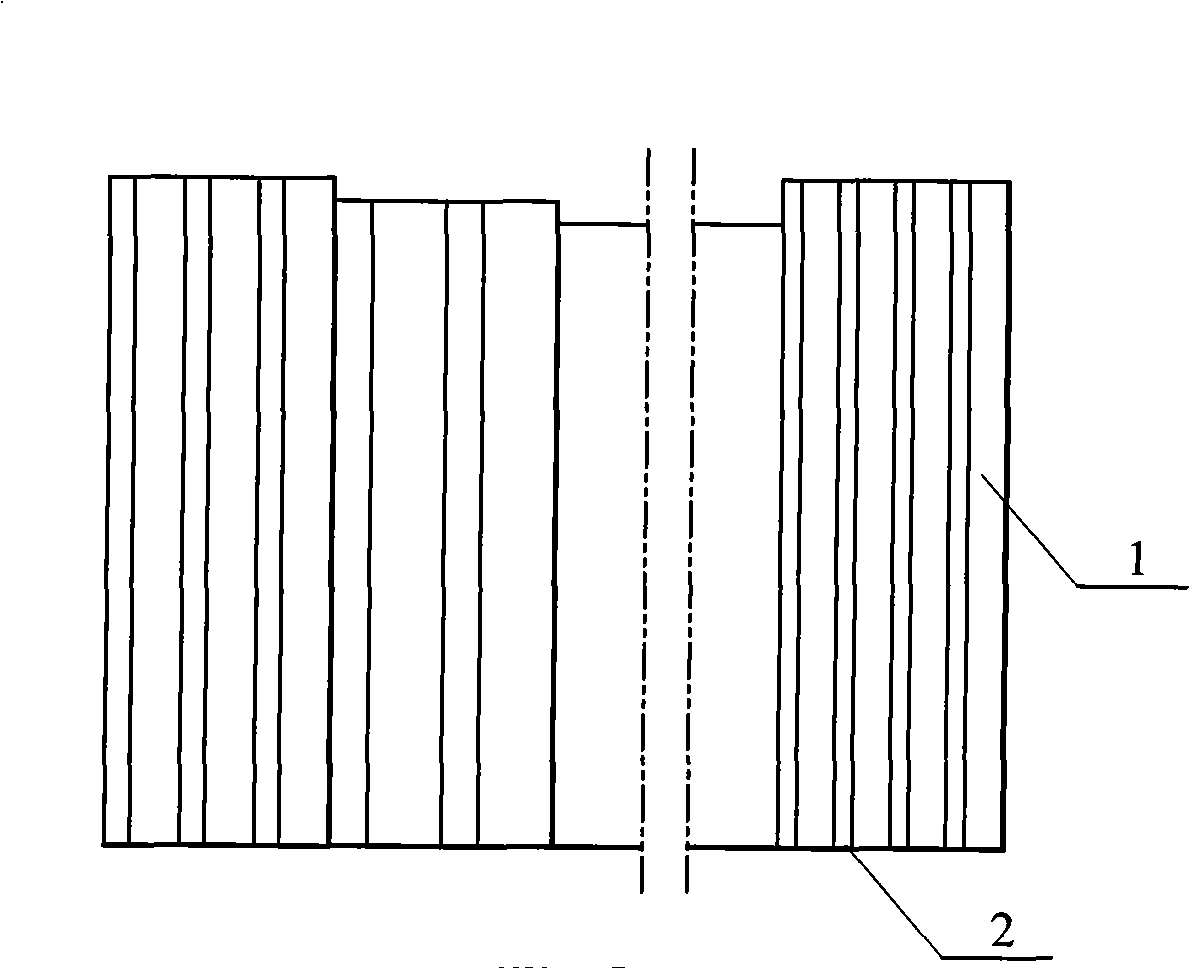

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 4 Describe this embodiment, the energy absorber of this embodiment includes a bottom plate 2; the energy absorber also includes at least two honeycomb material columns 1; the at least two honeycomb material columns 1 are arranged side by side and fixed on the bottom plate 2 (using adhesive connection mode), two adjacent honeycomb material columns 1 are close to each other and fixed (bonded), the size of the honeycomb cells 1-1 on the same honeycomb material column 1 is the same, and the honeycomb cells of each honeycomb material column 1 The shape of the unit 1-1 is a regular hexagon, the difference between the side lengths of the honeycomb unit 1-1 of two adjacent honeycomb material columns 1 is greater than or equal to zero, the The difference in thickness is greater than or equal to zero.

[0008] The setting method of two adjacent honeycomb material columns 1 adopts any one of the following three combinat...

specific Embodiment approach 2

[0009] Embodiment 2: The number of honeycomb material columns 1 in this embodiment is 2-10, which can meet the needs of different structural fields. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 The present embodiment will be described. The upper end surfaces of the 2 to 10 honeycomb material columns 1 described in the present embodiment are flush. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com