Multicolour LED vision image light source system for automatic grading of fruits

An automatic grading and visual image technology, applied in sorting, instruments, character and pattern recognition, etc., can solve the problems of low accuracy, high labor intensity, low efficiency, etc., and achieve stable performance, high resolution, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

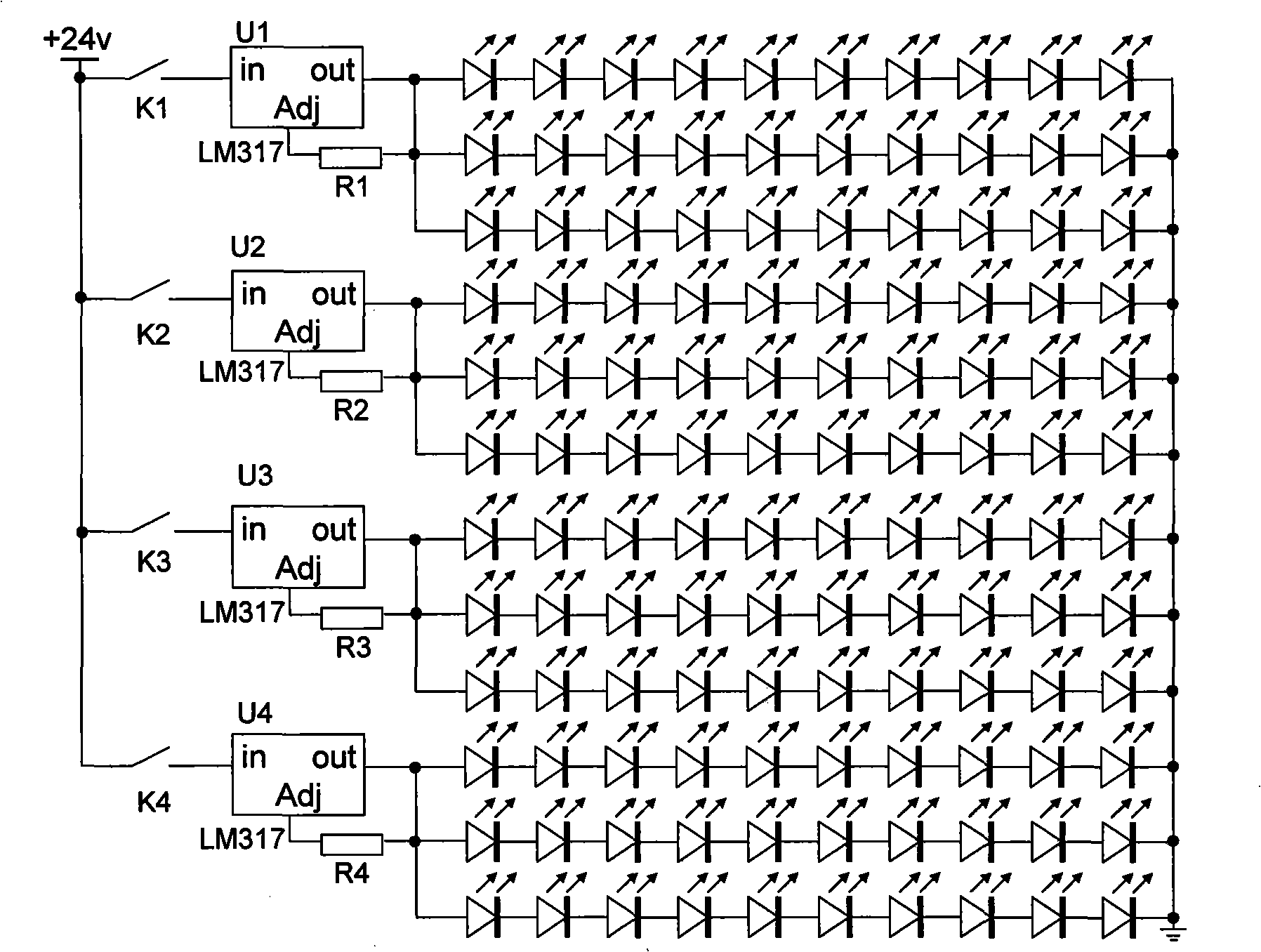

[0017] Such as figure 1 As shown, two LED array boards 1 and 2, which are composed of emitting red light, blue light, green light and infrared light emitting diodes, are symmetrically arranged on both sides of the fruit support platform, and the LED array boards 1 and 2 are placed obliquely at an angle of 45°; The digital camera 5 is vertically placed at 1 meter above the fruit supporting platform 4, and the computer 6 is connected with the digital camera 5 through a USB interface; the digital camera 5 can be controlled by the computer 1 to obtain fruit reflectance spectrum images under different irradiation light sources.

[0018] Such as figure 2 As shown, the LED array board for emitting light source is composed of three small boards spliced together, and each small board is composed of 10 red, blue, green, and infrared LEDs of the same color in the vertical direction and staggered in the horizontal direction. The placement distance between the LEDs is 10cm.

[0019] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com