Grounding electrode insulation screen structure and its setting method

A grounding electrode, insulation shielding technology, applied in the direction of connecting parts to protect grounding/shielding devices, magnetic field/electric field shielding, electrical components, etc., can solve problems such as occupation, increased land acquisition costs, and large land area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

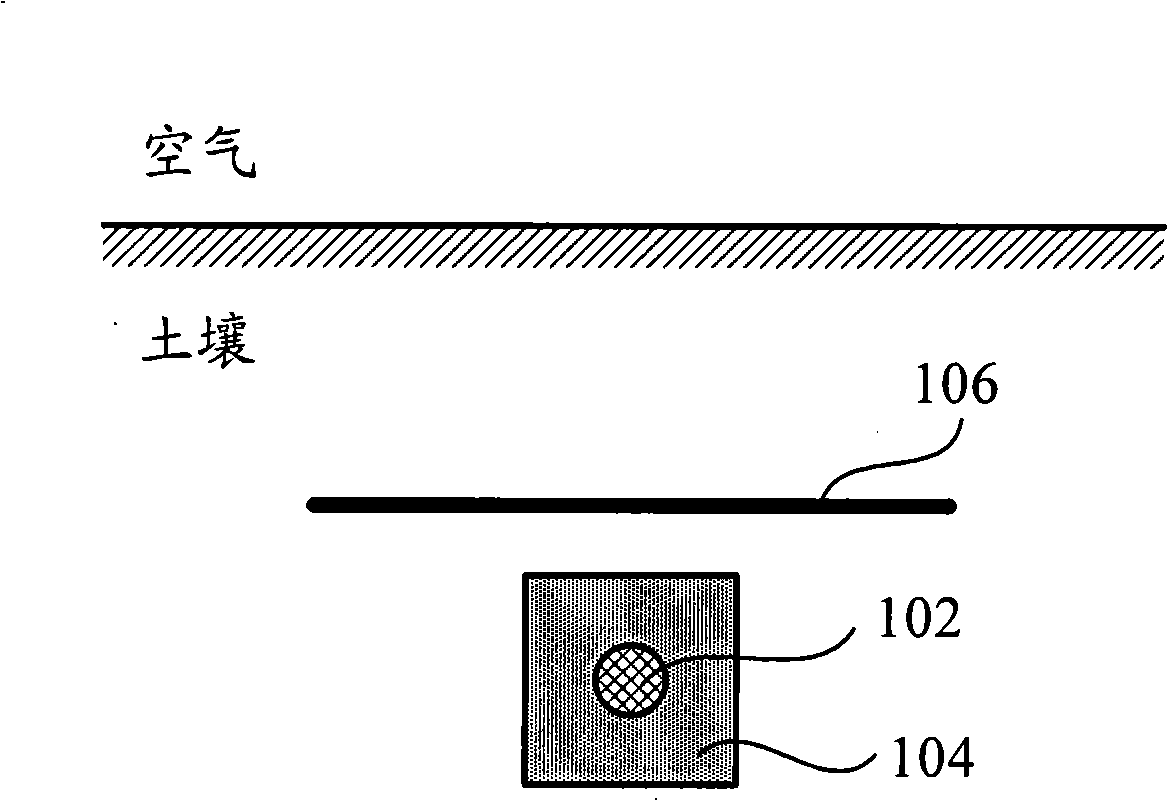

[0032] Exemplary embodiments of the present invention will be specifically described below with reference to the accompanying drawings.

[0033] The purpose of the present invention is to overcome the deficiencies of the prior art and propose a method for reducing the maximum step voltage of the DC grounding electrode without increasing the floor area of the grounding electrode and without greatly increasing the construction cost. Laying an insulating layer over the ground electrode prevents the current from flowing to the shallow soil and forces it to flow to the deeper soil, thereby reducing the surface step voltage.

[0034] In the specific implementation manner of the present invention, a DC ground electrode is used as an example for illustration, but those skilled in the art should understand that the specific implementation manner of the present invention is also applicable to the case of using an AC ground electrode.

[0035] Since most of the current DC grounding ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com