Semi-automatic layout machine

A spreader, semi-automatic technology, applied in the direction of AC motor control, AC motor direction control, motor generator/starter, etc. , The effect of reducing work intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

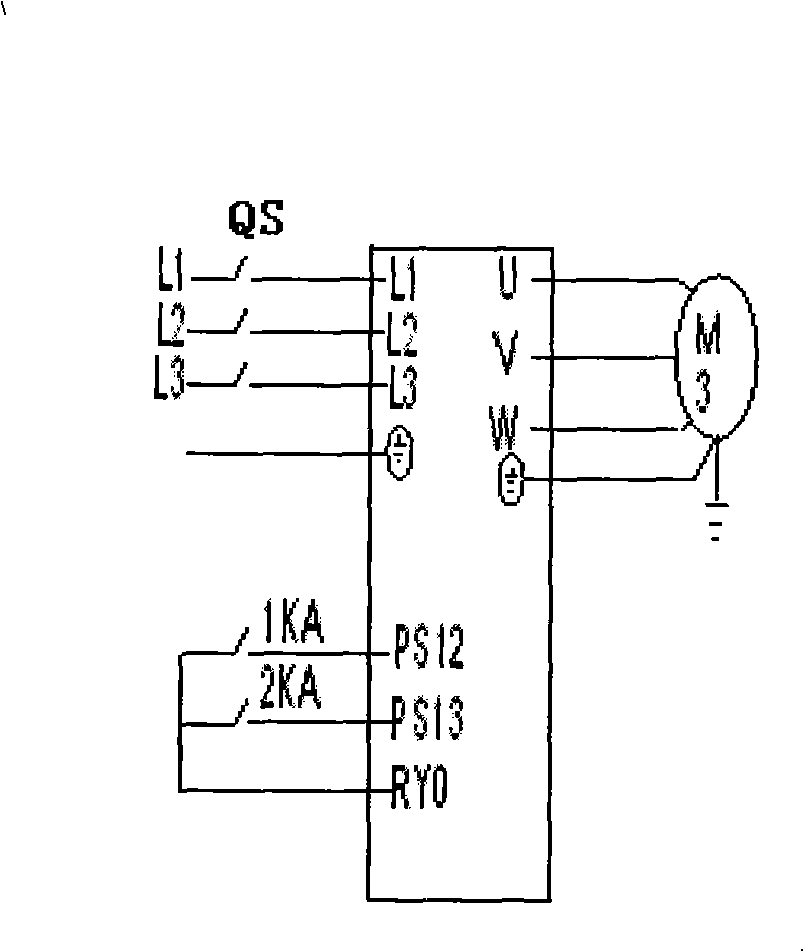

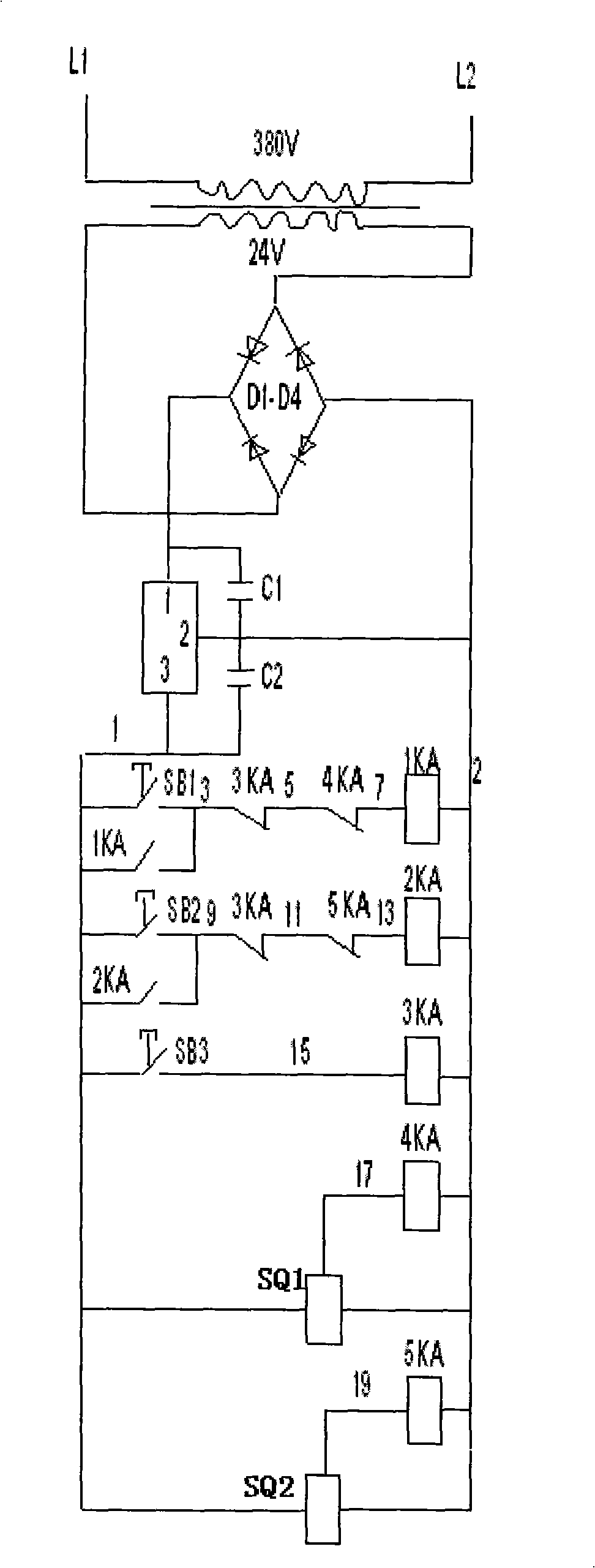

[0008] combined with figure 1 with 2 , to further describe the present invention:

[0009] Install a control box on one side of the original spreading machine, place circuit breakers, transformers, general relays, buttons and rectification and voltage stabilization devices in the control box, and install frequency converters, motors and proximity switches on the other side, and connect the proximity switches and Connect 4KA and 5KA in the control box, connect the forward and reverse start signals of the frequency conversion to 1KA and 2KA in the control box, and connect the output terminals U, V and W of the frequency converter to the motor respectively.

[0010] When it needs to run in the forward direction, press the start button SB1, the 1KA coil is energized and closed, the 1KA normally open contact is closed and self-protected, the other 1KA normally open contact is closed, and the RYO and PS12 are connected to the inverter to run forward signal, the motor runs forward....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com