Lubrication system of horizontal rotary compressor, its control method and application

A technology of rotary compressor and lubrication system, which is applied to rotary piston/swing piston pump components, mechanical equipment, machines/engines, etc. Can not lubricate and other problems, to achieve the effect of improving stability, superior oil supply and lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

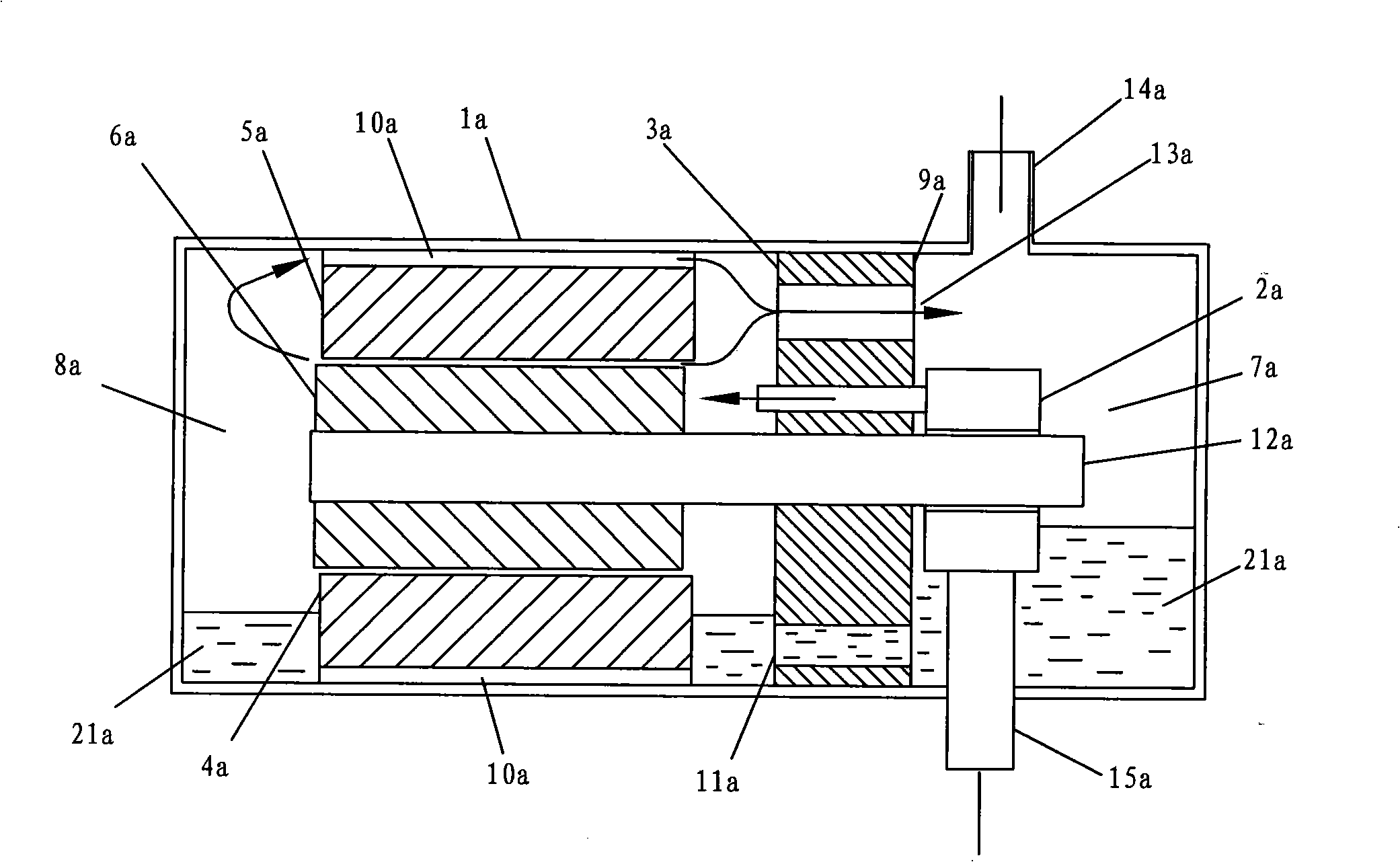

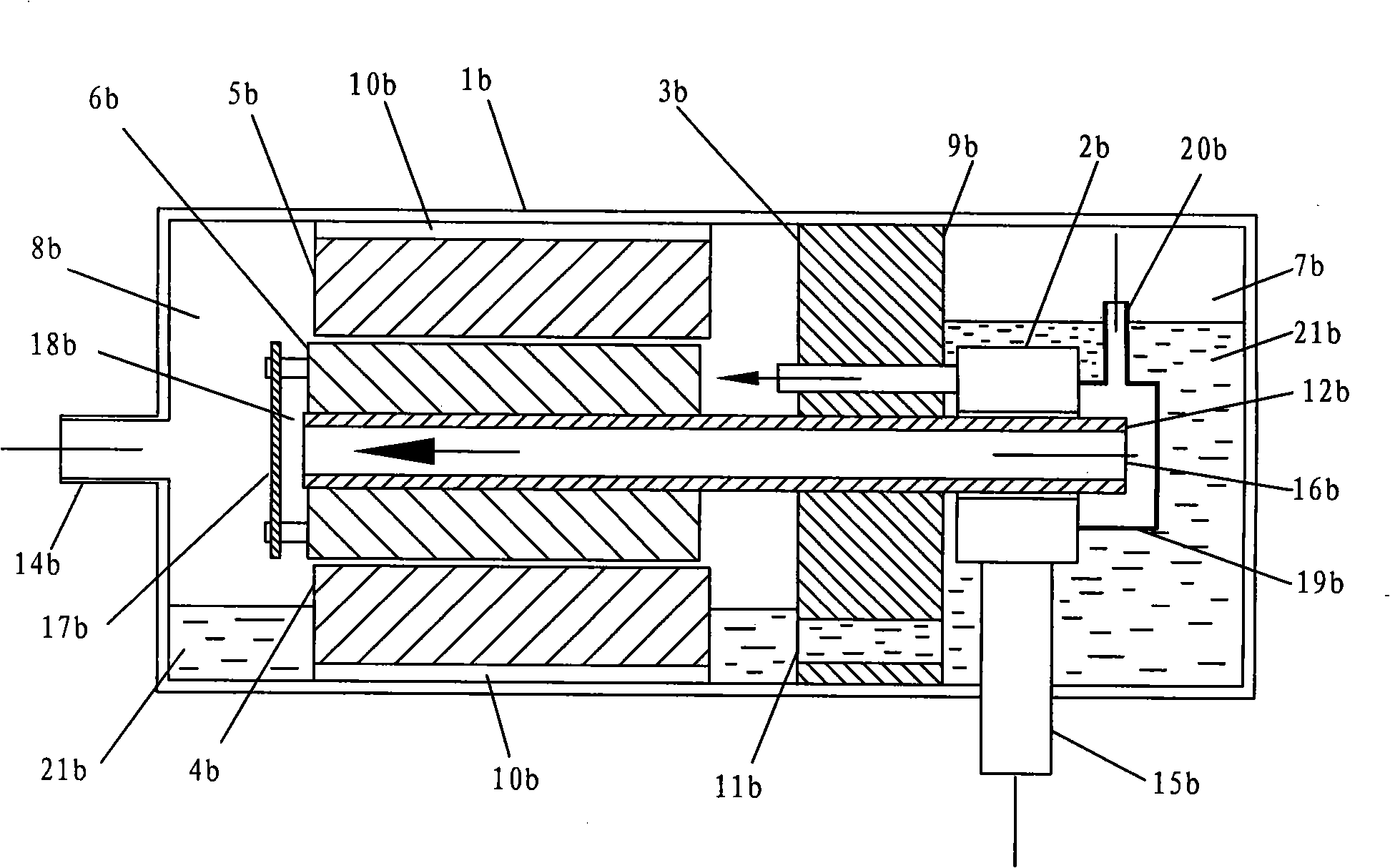

[0051] see figure 2 , the second horizontal rotary compressor seals an appropriate amount of second oil 21b in the cylindrical second casing 1b, and the oil is usually lubricating oil. The outer diameter of the second main bearing 3b among the constituent parts in the second compression main part is fixed in the inner diameter of the second casing 1b, which is hereinafter referred to as the second pump body assembly 2b. The second motor assembly 4b is composed of a second stator 5b and a second rotor 6b, and the outer diameter of the second stator 5b is fixed in the inner diameter of the second housing 1b. The outer diameter of the second stator 5b is generally provided with a second planar portion 10b having four cutouts. The second flat portion is a passage for exhaust gas or oil in the second motor chamber 8b. The second rotor 6b is fixed in the outer diameter of the second eccentric crankshaft 12b.

[0052] The second pump body assembly 2b is mainly composed of the sec...

no. 2 example

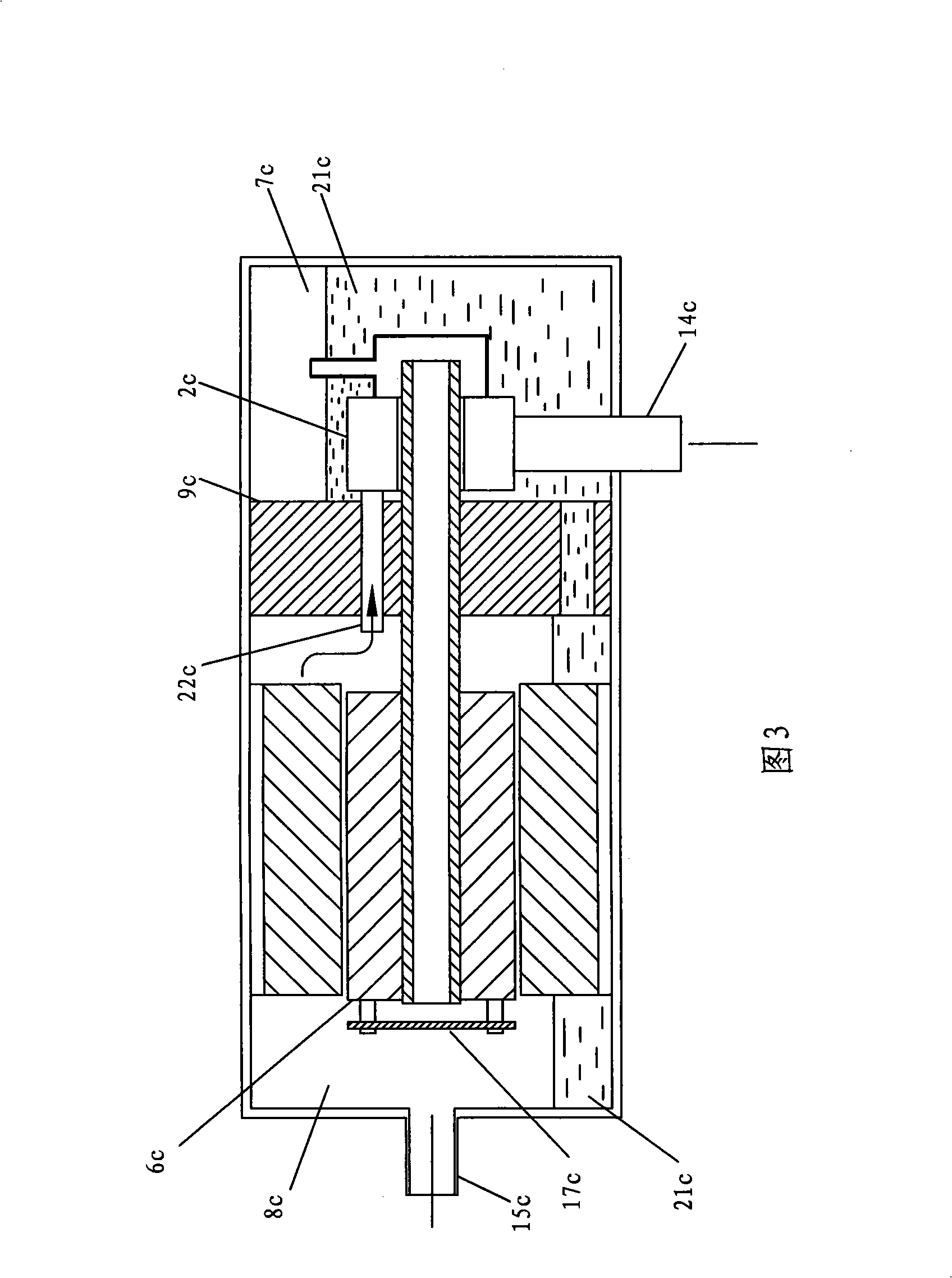

[0064] See Figure 3 for a design case of low back pressure inside the shell. and figure 2 Similarly, the inside of the third casing of the third horizontal rotary compressor is divided into two parts, the third oil storage chamber 7c and the third motor chamber 8c, by the third partition part 9c, and the bottom of the third partition part 9c is provided with a third The oil passage, the third through hole provided in the center of the third eccentric crankshaft communicates from the third oil storage chamber 7c to the third motor chamber 8c. The end of the third rotor 6c is fitted with a third end plate 17c. A third rotor gap with a small distance is provided between the end of the third rotor 6c and the third end plate 17c. In the third oil storage chamber 7c, the opening at one end of the third through hole is covered by the third oil cover, the hollow pipe installed on the top of the third oil cover, that is, the third vertical pipe, the third oil cover and the third oil...

no. 3 example

[0070] Referring to FIG. 4 , it is a sectional view of a fourth horizontal rotary compressor whose internal pressure of the shell is high pressure. The fourth housing of the fourth horizontal rotary compressor 31 is composed of a cylindrical fourth middle housing 32 located in the center and a fourth right housing 33 and a fourth left housing 34 welded and sealed at its open end . A fourth pump body assembly 35 and a fourth motor assembly 36 are fixed inside the fourth housing 32 . Two assembly feet are installed on the lower side of the outside of the fourth housing 32 : a fourth assembly foot 37 and a fourth assembly foot 38 . An appropriate amount of fourth oil 39 is sealed inside the fourth housing. The fourth motor assembly 36 is composed of a fourth stator 41 and a fourth rotor 42 . The fourth stator 41 has a fourth planar portion 43 having four cutouts on the outer diameter portion. The fourth stator 41 is fixed at the inner diameter of the fourth housing, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com