Coal ash light insulated wall board and method for producing the same

A technology of thermal insulation wallboard and fly ash, which is applied in the direction of chemical instruments and methods, manufacturing tools, clay preparation equipment, etc., can solve the problems of no light-weight thermal insulation wallboard, etc., and achieve easy handling and installation, light weight, and reduce Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

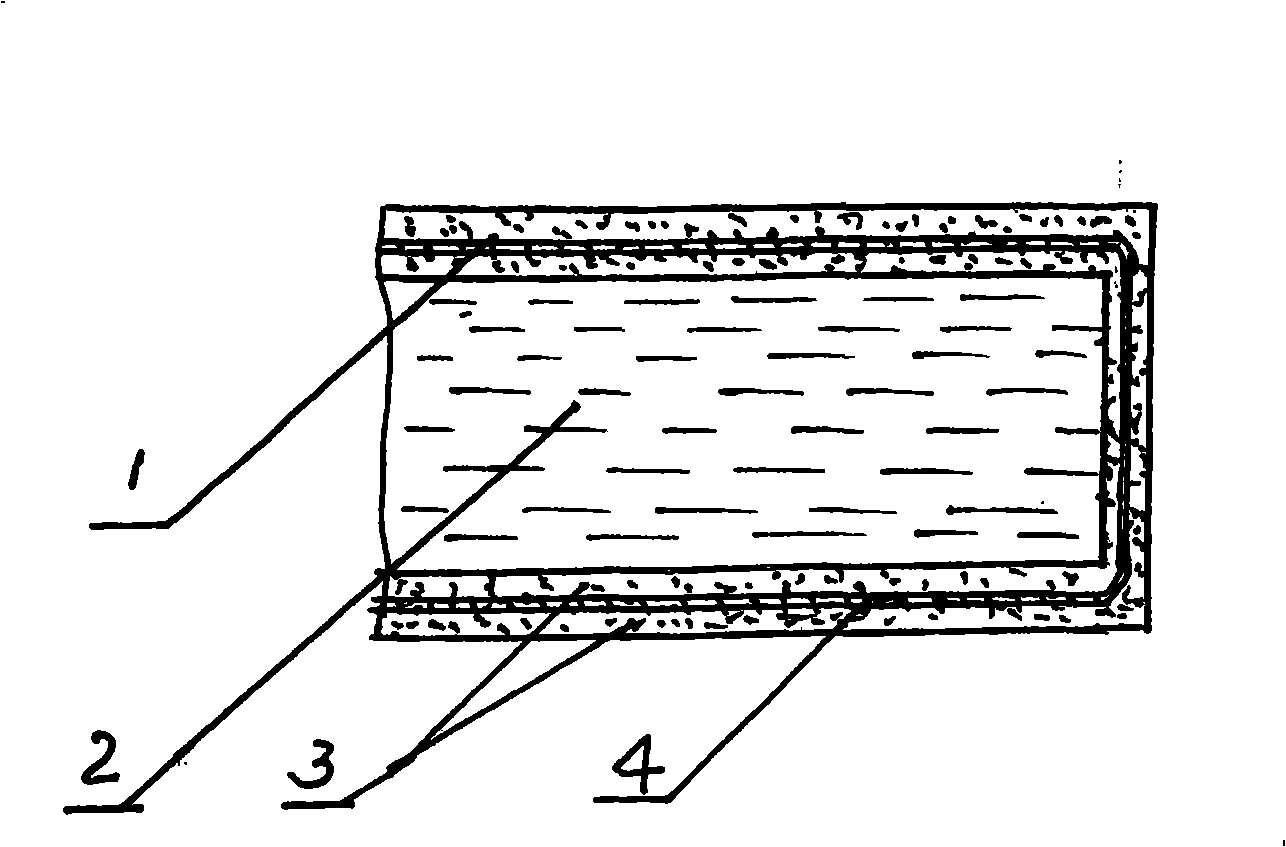

[0017] like figure 1 As shown, the thermal insulation wallboard of the present invention is covered with a layer of shell 1 on the outer surface of the polystyrene foam board 2, and the shell 1 is made of a layer of alkali-resistant glass fiber mesh 4, 30-40 parts (weight) of fly ash, The mixed slurry solidified layer 3 is formed by mixing 60-70 parts (weight) of ordinary portland cement, 10 parts of construction adhesive and 1 part of auxiliary agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com