Tool vehicle

A tool car and car body technology, which is applied to manufacturing tools, workshop equipment, etc., can solve the problems of inconvenient opening and closing, unreasonable drawer locking mechanism, waste of packaging materials, etc., to save storage and transportation costs, open and lock convenient and fast, The effect of saving packaging materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

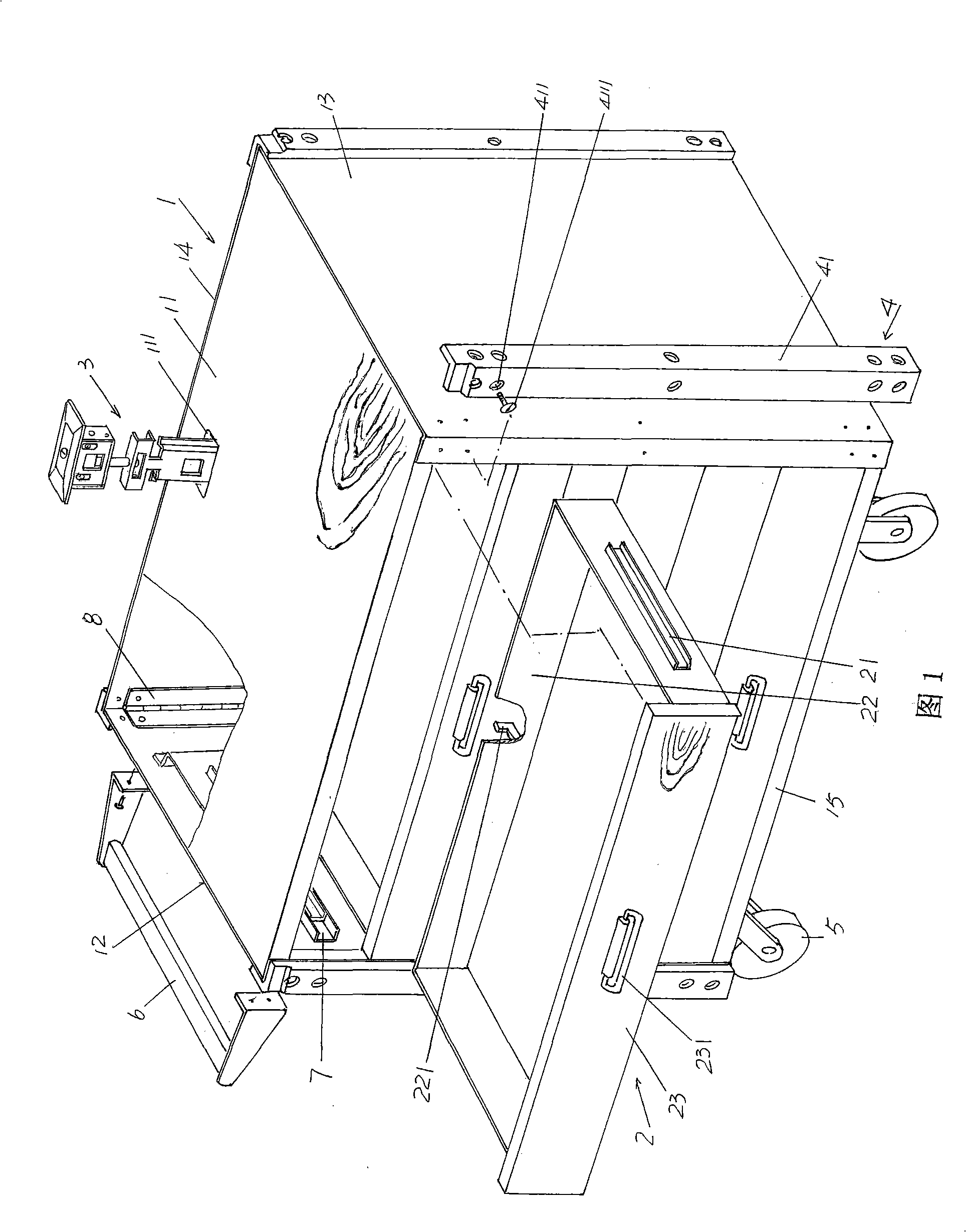

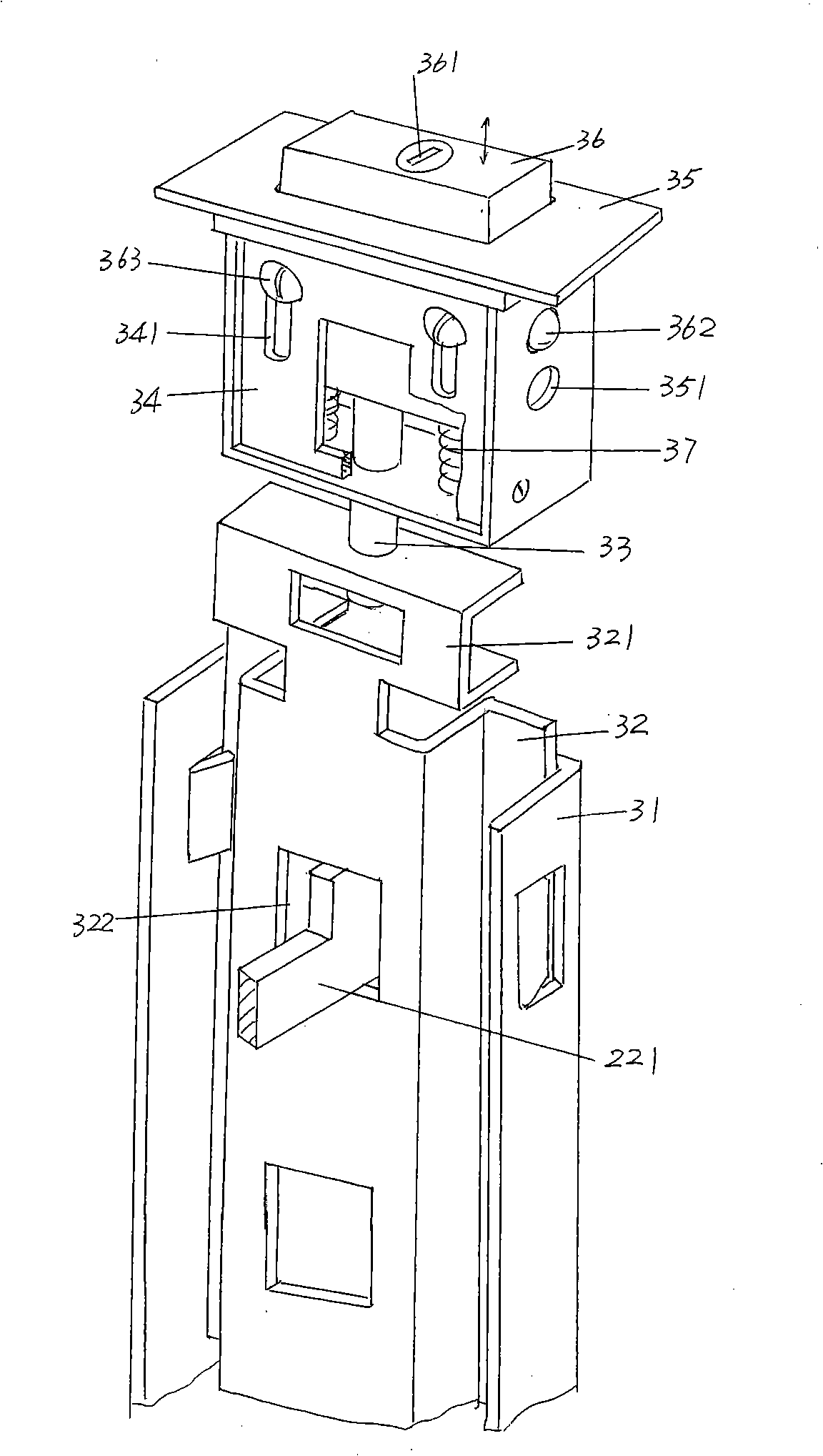

[0022] Please refer to the attached drawings. It shows a car body 1 whose overall shape is a rectangular body, more specifically a rectangular parallelepiped. The car body 1 is composed of a workbench panel 11, left and right side panels 12, 13, a rear panel 14 and a bottom panel 15. When the assembly is to be implemented (the assembly is not required under transportation and storage conditions), the junction (also called the assembly) between the inner side of the left side plate 12 and the inner side of the rear plate 14 is connected by a hinge 8. The same , The junction between the inner side of the right side plate 13 and the inner side of the rear plate 14, that is, the assembling place, is connected by a hinge 8, while the bottom of the left and right side plates 12, 13 and the bottom of the rear plate 14 are screwed or similarly fastened. The piece is fixed to the bottom plate 15. In addition, grooves with widths adapted to the thicknesses of the left and right plates 12, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com