Form relieved tooth radiator and manufacturing process thereof

A technology for radiators and shoveling teeth, which is applied in the field of shoveling tooth radiators and its manufacturing process, which can solve the problem of the difficulty in balancing the space occupied by the radiator with the heat dissipation efficiency, the inability to meet the needs of the miniaturization of home appliances, and the increase in the operating power of power devices, etc. problems, to achieve the effect of convenient maintenance and replacement, simple structure, and improved assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]In order to deepen the understanding of the present invention, the present invention will be further detailed in connection with the embodiments and the accompanying drawings, which is not intended to be construed as limiting the scope of the invention.

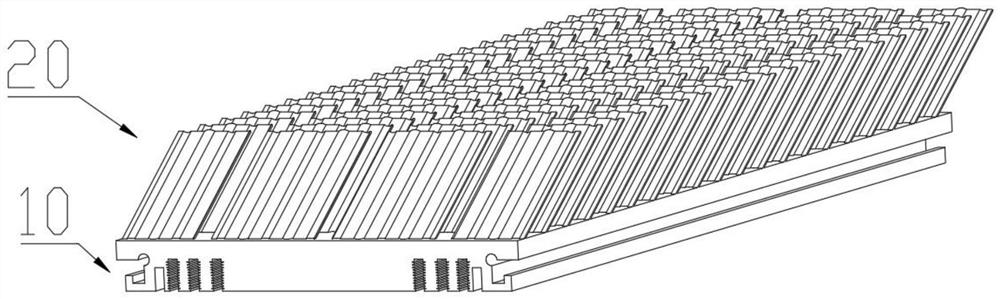

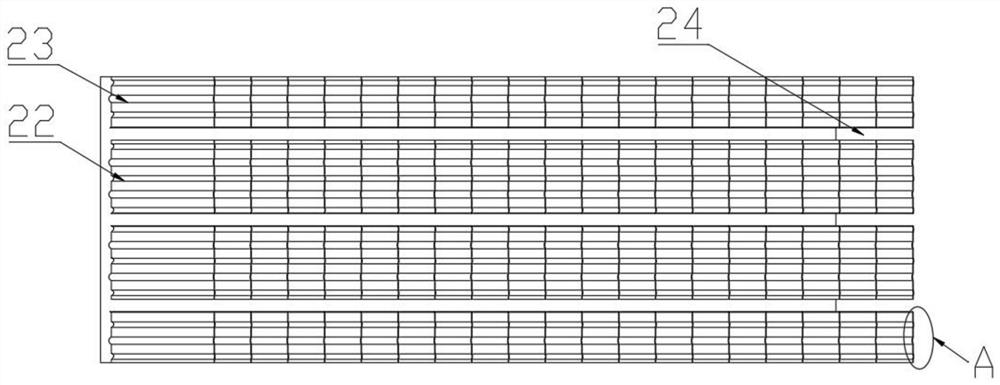

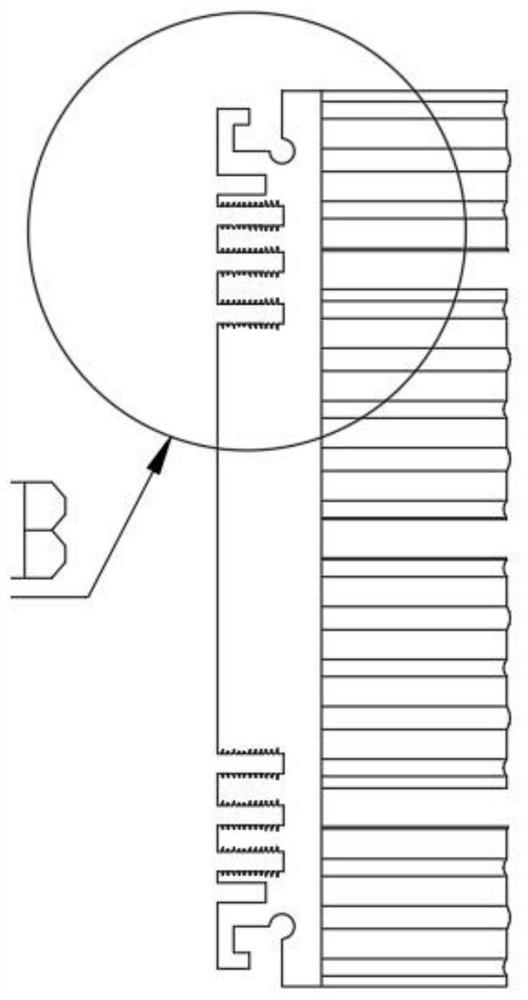

[0029]Such asFigure 1-8As shown, a shovel and a heat dissipator comprising a mounting portion 10 and a heat dissipation portion 20, the heat dissipation portion 20 is located on the upper surface of the mounting portion 10, and the heat dissipation portion 20 comprises a ripple arm 21 provided with a plurality of arrays, the corrugation There is an α angle between the shovel teeth 21 and the mounting portion 10, the surface of the strip arm is wavy; the bellows 21 includes two columns of wide rippled shovel teeth 22 and two narrow corrugated shovel teeth groups 23; The narrow-striped shovel teeth 23 are located on both sides of the wide ripple shovel teeth group 22; the adjacent columns are provided with a spacing air groove 24....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com