Method for making flash memory

A memory and flash technology, applied in the field of making flash memory, can solve problems such as memory defect operation life, save process cost and avoid read and write failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

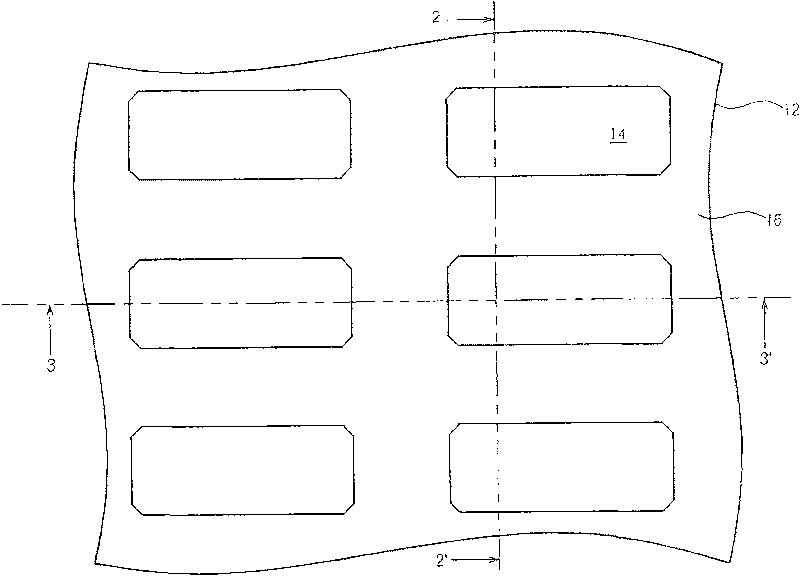

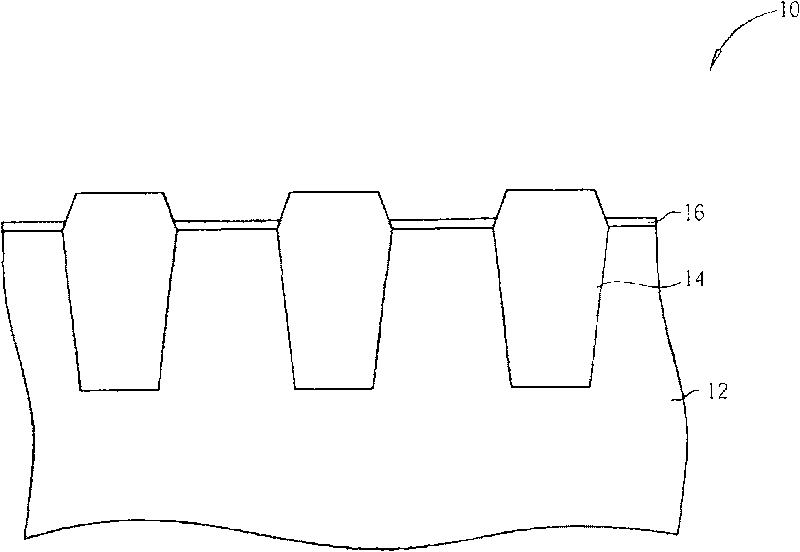

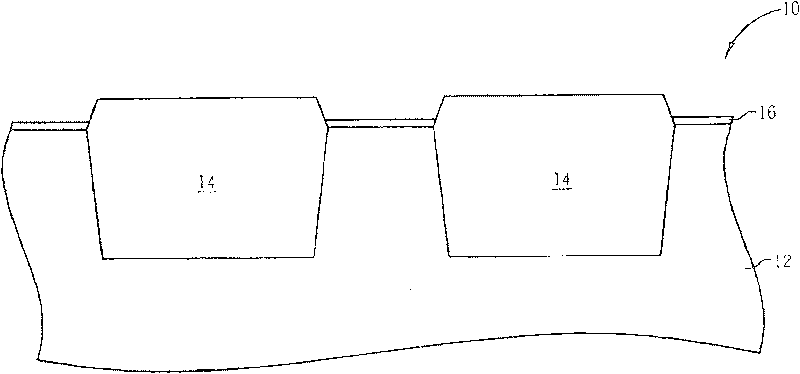

[0031] Please refer to FIGS. 9-19. FIGS. 9-19 are schematic diagrams of the process of the method for manufacturing the flash memory 50 of the present invention. In this embodiment, the flash memory 50 is a split-gate flash memory. First, a semiconductor substrate 52 is provided, which can be a silicon substrate, or a P-type or N-type silicon substrate. Picture 9 Only a partial area of the semiconductor substrate 52 is shown, and Picture 10 for Picture 9 A schematic cross-sectional view of the semiconductor substrate 52 shown along the tangent line 10-10' (that is, the Y direction). Next, a plurality of insulating shallow trench structures 54 are formed on the surface of the semiconductor substrate 52. Since the upper surface of the insulating shallow trench structure 54 is higher than the surface of the semiconductor substrate 52, there is a recessed area 55 between adjacent insulating shallow trench structures 54 respectively. In addition, the semiconductor substrate 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com