Ultrasonic flowmeter

An ultrasonic and flowmeter technology, which is used in the measurement of flow/mass flow, liquid/fluid solid measurement, measurement devices, etc., and can solve problems such as long periods of time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

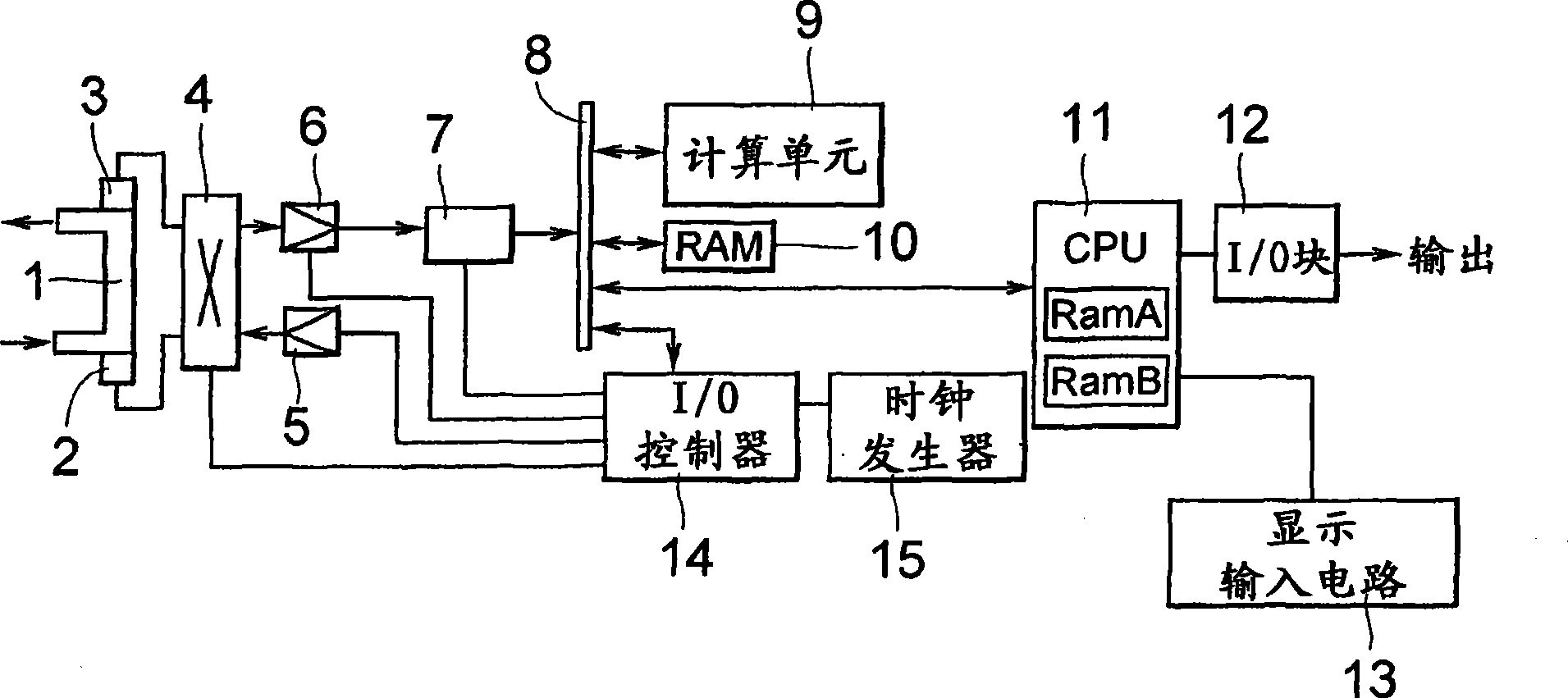

[0035] figure 1 is a block diagram showing an embodiment of an ultrasonic flowmeter according to the present invention. The fluid whose flow is to be measured flows through conduit 1 . At upstream and downstream positions of the catheter 1, ultrasonic vibrating elements 2 and 3 are provided, respectively. It should be noted that the ultrasonic element 2 is used to transmit ultrasonic waves and receive ultrasonic waves transmitted from the ultrasonic vibrating element 3 , and similarly, the ultrasonic vibrating element 3 is used to transmit ultrasonic waves and receive ultrasonic waves transmitted from the ultrasonic vibrating element 2 .

[0036] The ultrasonic vibrating elements 2 and 3 are selectively connected to a transmission amplifier 5 and a reception variable gain amplifier 6 via a converter or a multiplexer 4 . The output of the receiving variable gain amplifier 6 is connected to the computing unit 9 , RAM 10 and CPU 11 via the A / D converter 7 and the data bus 8 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com