Eight-terminal voltammetry measuring method of direct current resistance

A technology of DC resistance and measurement method, which is applied in the direction of measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve problems that affect the correctness of maintenance decisions, unsatisfactory results, and measurement errors, etc., to achieve measurement Convenience, time and manpower saving, cleverly conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

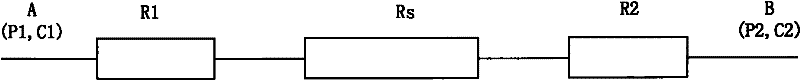

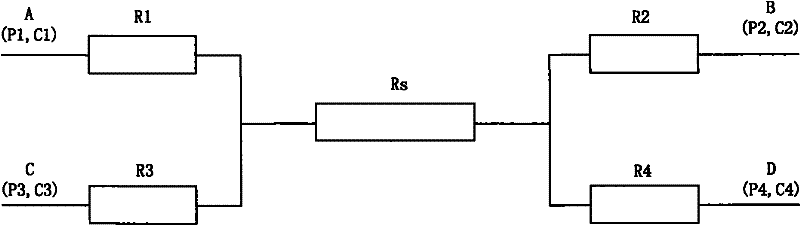

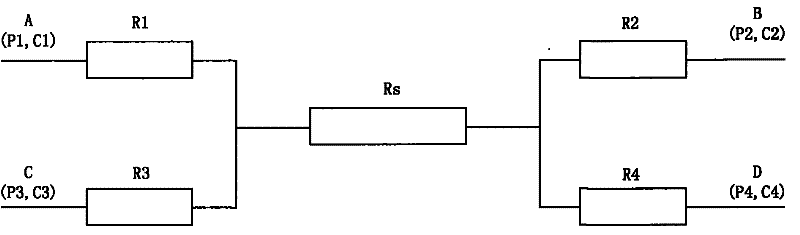

[0022] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] After long-term research on field measurement work, on the basis of four-terminal button voltammetry measurement, a pair of measuring elements are added, that is, four-terminal buttons are added, and eight-terminal button voltammetry is used for DC resistance measurement. .

[0024] Such as figure 2 As shown, an eight-terminal button voltammetry DC resistance measurement method is as follows:

[0025] Connect two current terminal buttons (C1, C3) and two voltage terminal buttons (P1, P3) to one end of the electric equipment under test, and connect two current terminal buttons (C2, C4) and two Voltage terminal button (P2, P4);

[0026] The current terminal C1 and the voltage terminal P1 constitute a measuring element, the internal resistance of which is R1, and its head end is A; the current terminal C2 and the voltage ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com