Bamboo-plastic composite floor and pavement method thereof

A bamboo-plastic composite and floor technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of airtightness, inconvenient disassembly, high cost, and achieve simple and convenient operation, ingenious structural design, and long life cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

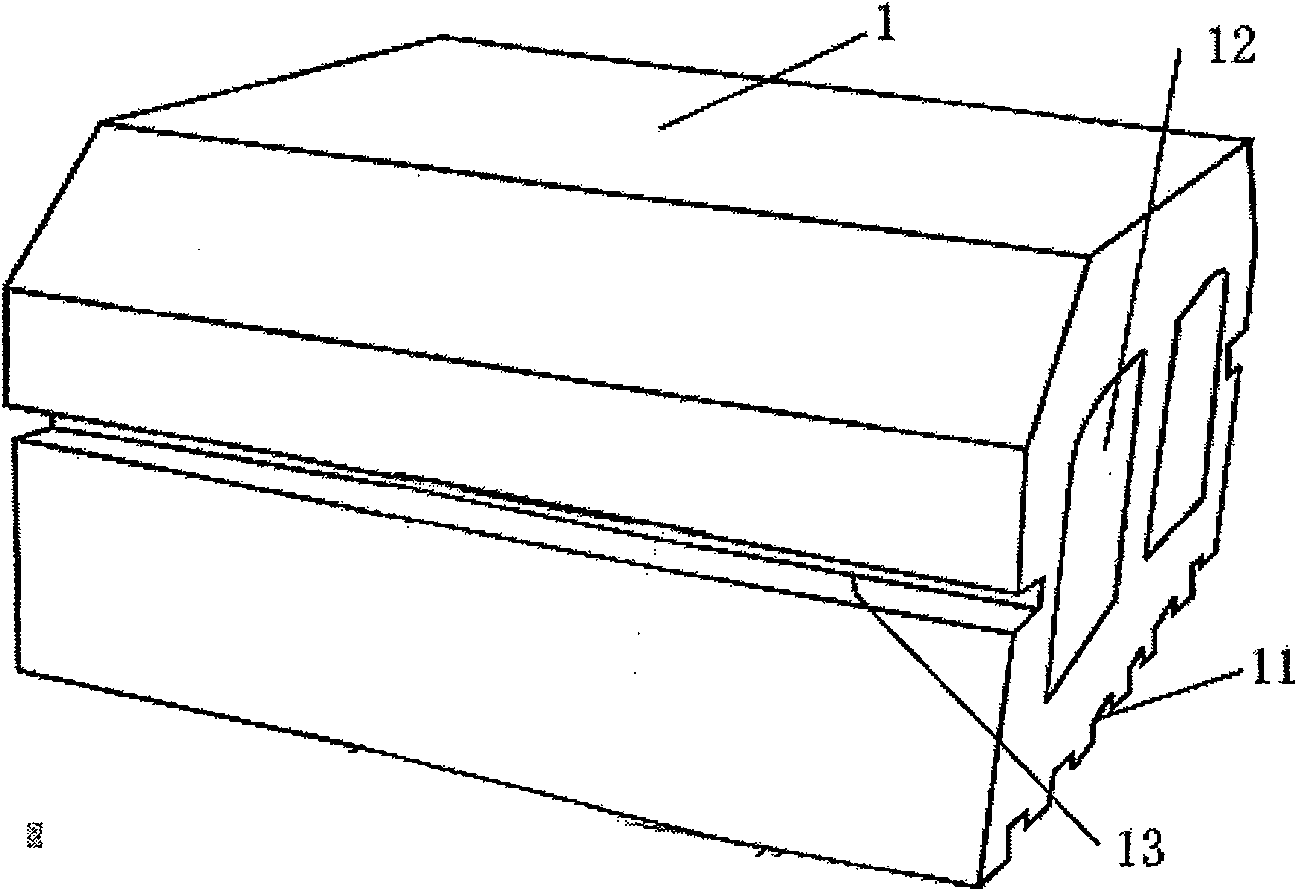

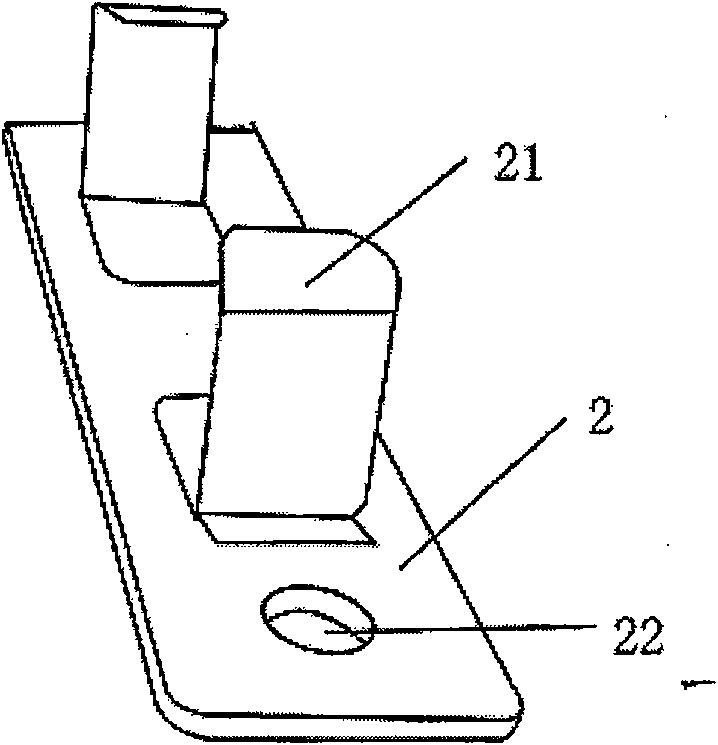

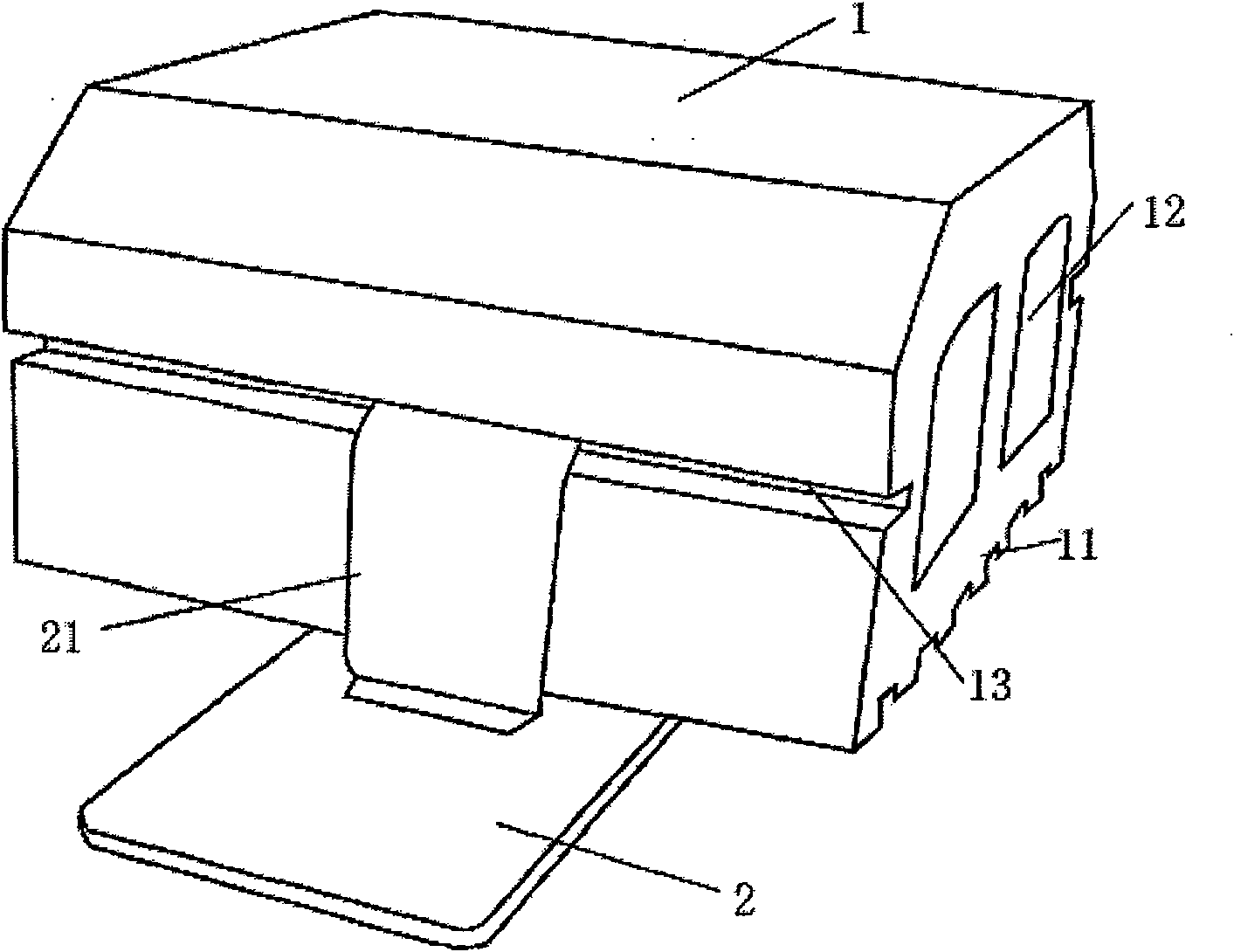

[0011] Such as figure 1 , figure 2 As shown, this embodiment includes a floor module 1 and a card key 2. The bottom of the floor module 1 is provided with 6 running water tanks 11, and the middle part of the module body 1 is provided with a pentagonal drainage hole 12. The two sides of the floor module 1 are respectively There is a corresponding card slot 13; the card key 2 is provided with an inverted "L"-shaped hook 21, and the distance between the hooks corresponds to the width of the floor module, ensuring that the card slots 13 on both sides of the floor module are fastened , The two ends of the card key 2 are provided with screw holes 22 for fixing. The card key is made of stainless steel with a thickness of about 1.5cm.

Embodiment 2

[0013] Such as Figure 4 As shown, the card key 2 of this embodiment is provided with a "T" shaped hook. Other technical schemes are the same as embodiment 1.

[0014] Such as image 3 , Figure 4 As shown, the pavement method of this embodiment 1 or 2: insert the floor module 1 into the card key 2, and then clamp the hook 21 of the corresponding card key 2 into the card slots 13 on both sides of the floor module 1, and then pass the The screw holes 22 on the slot 13 are fixed in proper positions. The operation can be repeated continuously according to the size of the paving area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com