Supporting method of factory building roof system at super large column-removed spacing

A roofing system and support method technology, applied in the direction of roofs, building components, buildings, etc., can solve the problems of increased steel consumption, difficult to bear the load of brackets, and the overall height of the workshop, so as to achieve uniform roof layout and force transmission. The way is simple and the effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

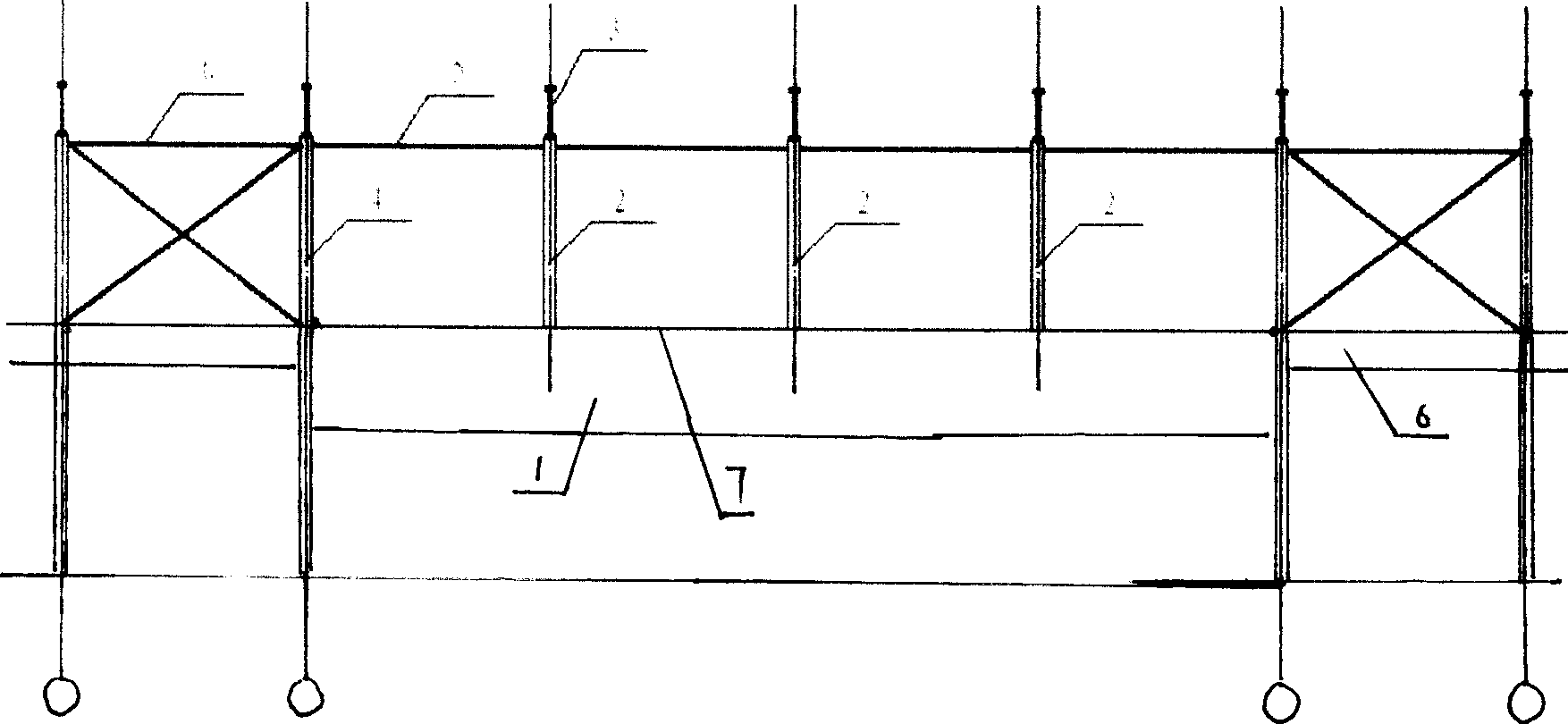

[0010] exist figure 1 Among them, on the top surface of the box crane beam 1 at the super large column spacing of 7, the steel column 2 hinged to it is arranged on both sides according to the normal column spacing of 6, the column top is hinged with the steel roof truss 3, and the column foot is connected with the large box crane Beam 1 is hinged. The steel column 2 on the beam, the upper column 4 of the workshop column on both sides of the pumping column, and the upper column of other factory buildings in this column are all equipped with force transmission components such as the rigid tie rod 5 on the top of the column in a normal manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com