Coal hot-air rotary oven

A technology for burning coal and ovens, applied in the field of ovens, can solve problems such as unreasonable structure, environmental pollution, large heat loss, etc., and achieve the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

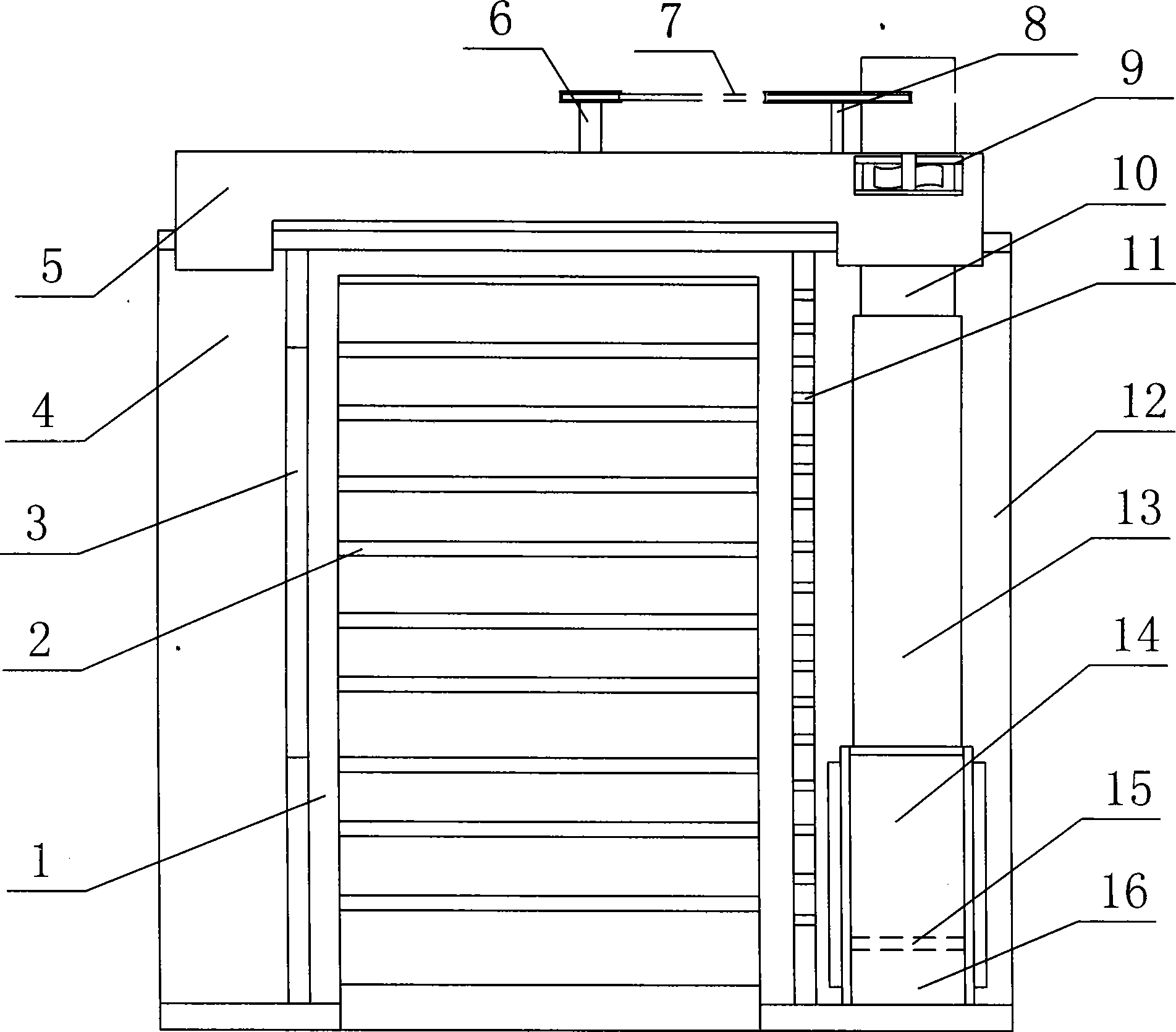

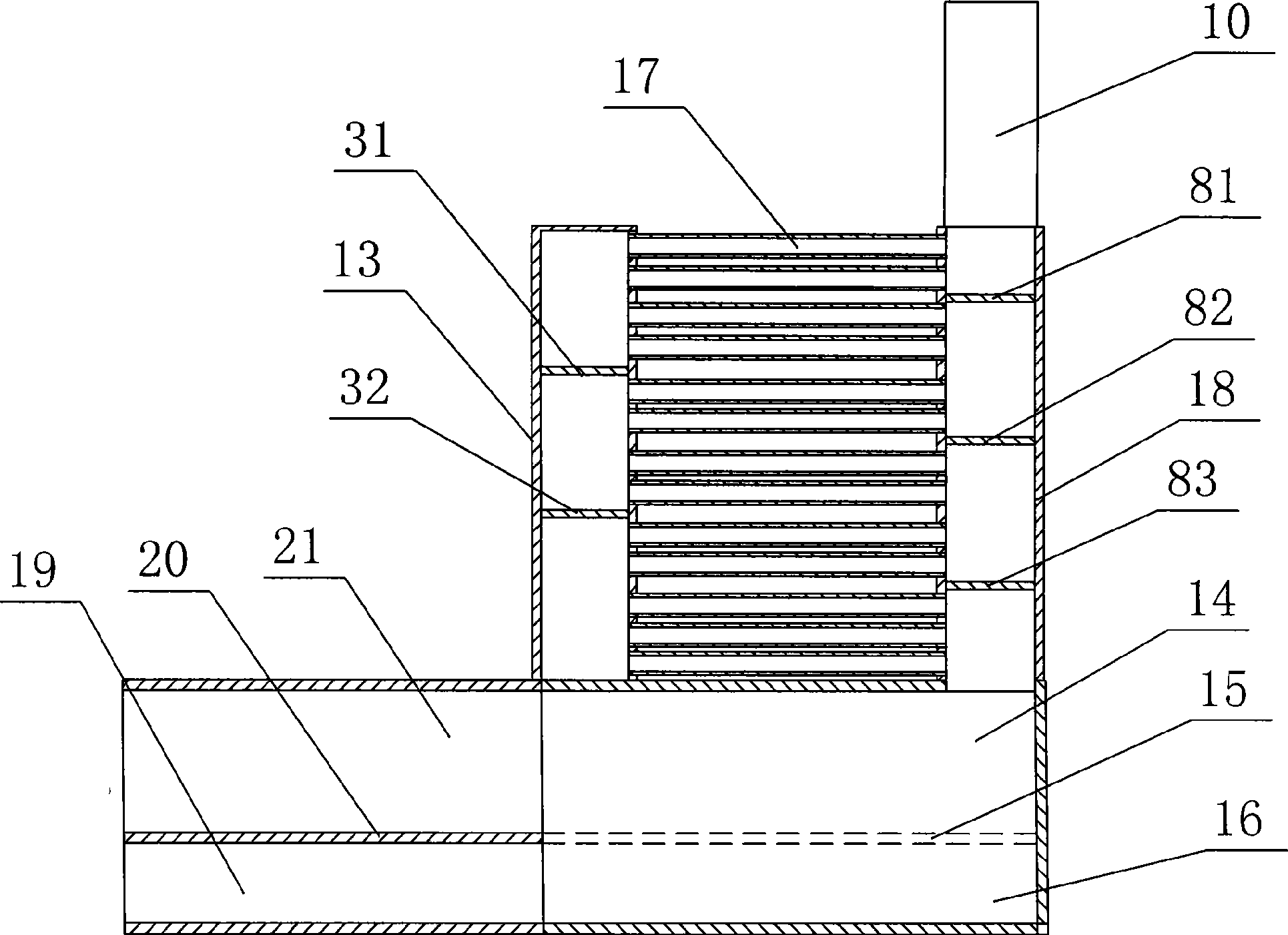

[0016] A coal-fired hot air rotary oven, such as figure 1 , figure 2 As shown, it includes a box composed of a combustion chamber 12, a baking chamber 1 and a high temperature chamber 4, the baking chamber 1 is in the middle of the casing, and the combustion chamber 12 and the high temperature chamber 4 are respectively arranged on both sides of the baking chamber 1. Combustion chamber 12 is made of high-temperature-resistant materials, and a partition is provided between it and baking chamber 1, and circulation air holes 11 are arranged on the partition, and a partition is also provided between high-temperature chamber 4 and baking chamber 1. The vent window 3 that opening size can be adjusted is installed on the board. Baking chamber 1 is provided with baking frame 2, and baking frame 2 is provided with chassis, and chassis is movably inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com