Special caliper for shaft key groove

A shaft key and caliper technology, which is applied in the field of measuring devices for shaft key grooves, can solve the problems of multiple measuring instruments and inconvenience, and achieve the effects of convenient use, simple structure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

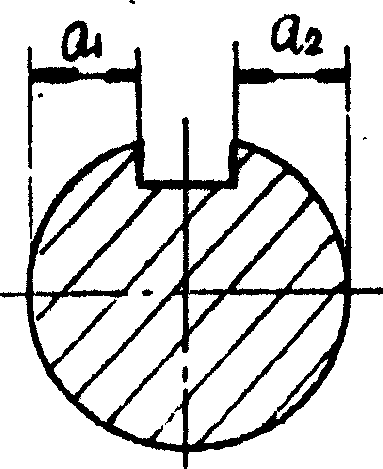

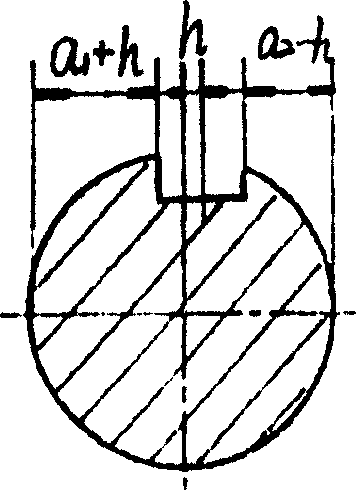

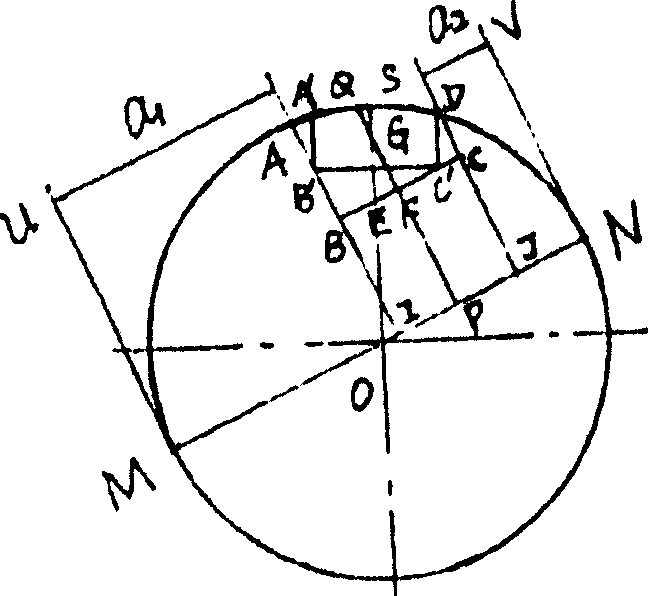

[0022] Such as Figure 4 As shown, the special caliper for shaft keyway is made up of main ruler 3, auxiliary ruler 12, display 5, sounding ruler 9, ruler frame 8 and sounding accessory 15. The main chi includes parts such as the upper measuring claw 1 of the main chi, the lower measuring claw 10 of the main chi, the chi body 14 of the main chi. The auxiliary chi includes parts such as the upper measuring claw 2 of the auxiliary chi and the lower measuring claw 11 of the auxiliary chi. Display 5 is divided into two modes of electronic digital display and vernier reading. Vice chi 12, chi frame 8, sounding annex 15 all can be moved or fixed on main chi chi body 14. The sounding ruler 9 and the display 5 are fixed on the auxiliary ruler 12. The ruler frame 8 is connected with the auxiliary ruler 12 through the guide rod 7, and the guide rod can move a certain distance in the hole of the auxiliary ruler to compress the force-measuring bullet 6.

[0023] Implement symmetry mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com