Instantaneously heated hydroelectric separating heater

A water-electricity separation and heater technology, which is used in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of complex manufacturing process, uneven heating, and many welding points, so as to increase the heat transfer area and reduce The effect of low heat loss and power attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

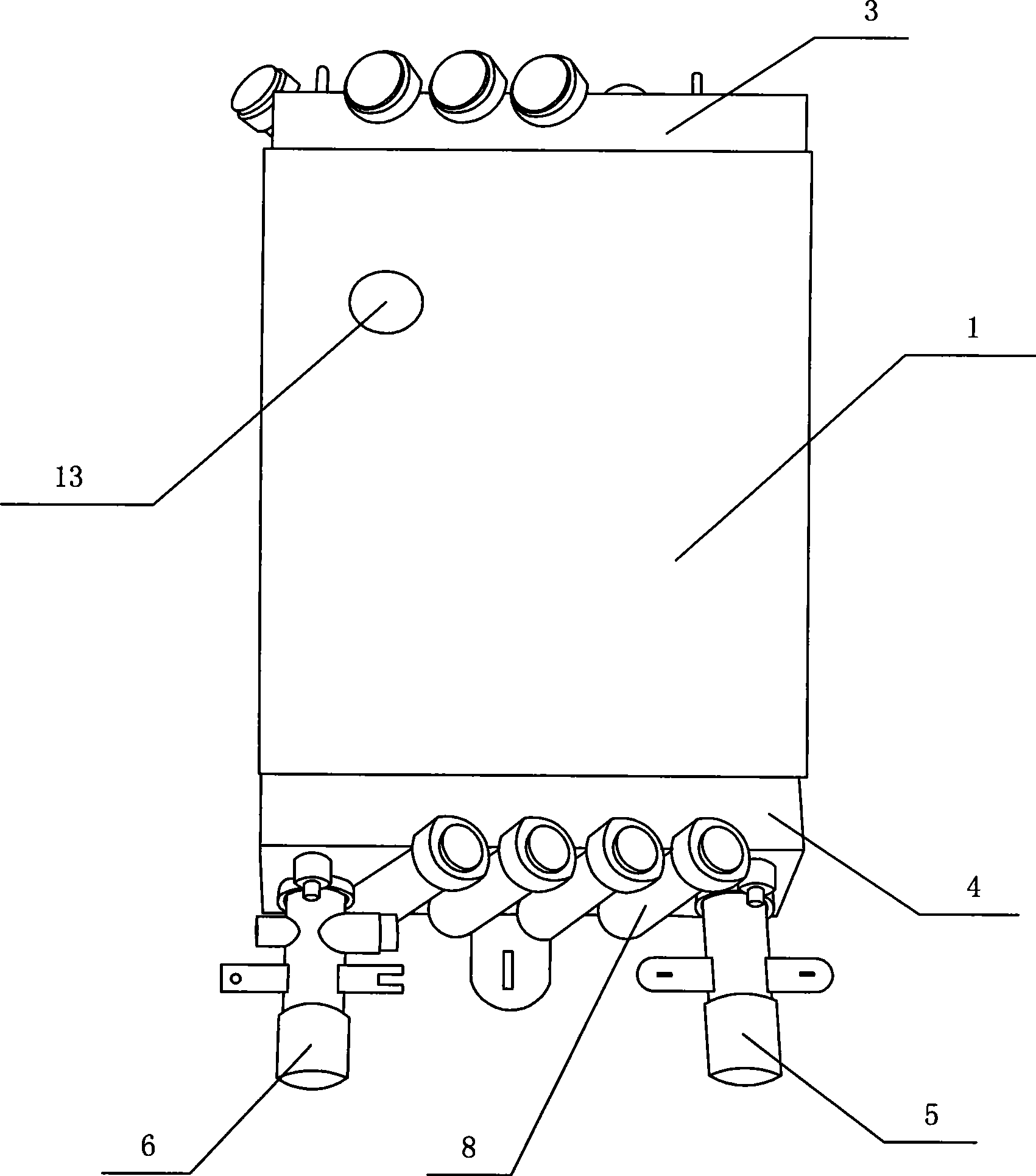

[0023] Such as figure 1 As shown, an instant water and electricity separation heater includes a casing 1, a circulation diversion system, a heating assembly and a control system.

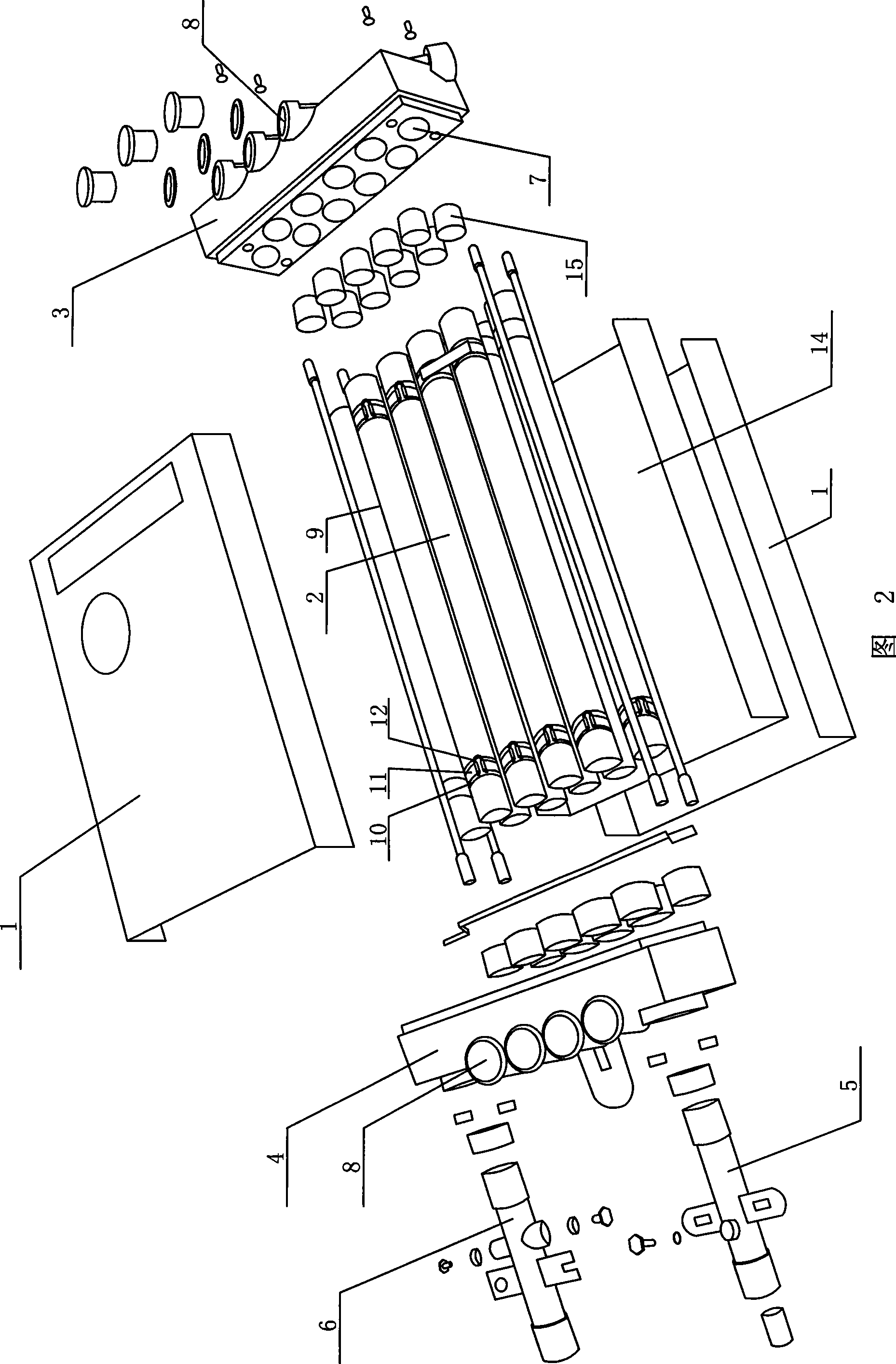

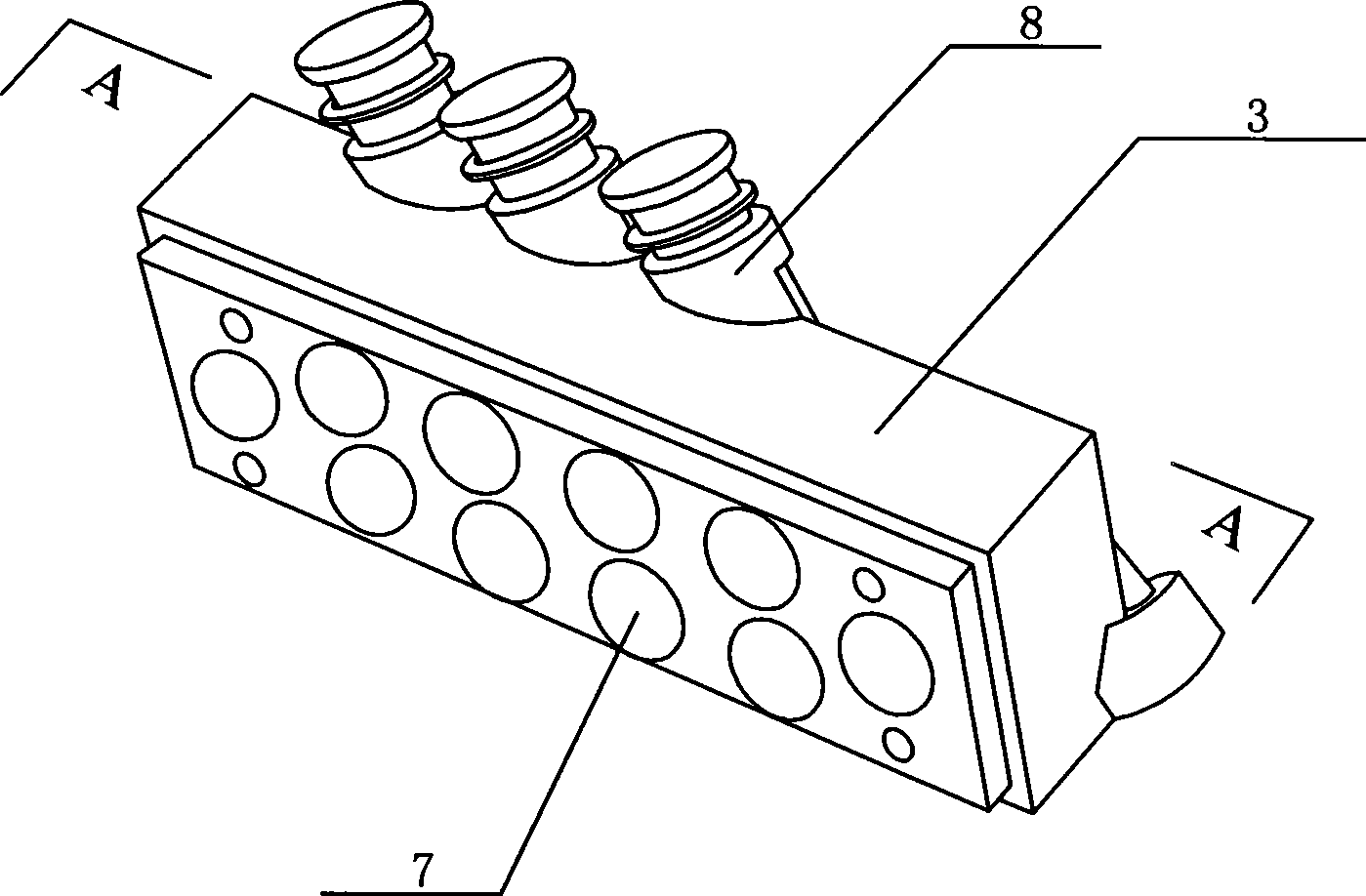

[0024] As shown in Figure 2, the circulation diversion system is composed of ten electric heating tubes 2 arranged staggered up and down and the upper diversion chamber 3 and the lower diversion chamber 4 at both ends. The lower diversion chamber 4 is connected to the water inlet pipe 5 and the water outlet pipe. 6. A displacement control valve (not shown in the figure) is provided in the water inlet pipe 5, and ten diversion holes 7 corresponding to the electric heating tubes 2 are provided on the upper diversion chamber 3 and the lower diversion chamber 4, as image 3 As shown, each adjacent upper and lower two diversion holes 7 are communicated through a diversion groove 8, as Figure 4 As shown, the diversion groove 8 is arranged along the arrangement direction of the adjacent upper and lower d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com