Screw conveyor for discharging reduced iron from rotary hearth reduction furnace

A screw conveyor and rotary furnace bottom technology, which is applied to hearth furnaces, furnaces, furnace components, etc., can solve the problems of reducing the weight of the screw conveyor, adding spring parts, and increasing costs, so as to improve the water cooling effect and prolong wear The effect of life and equipment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

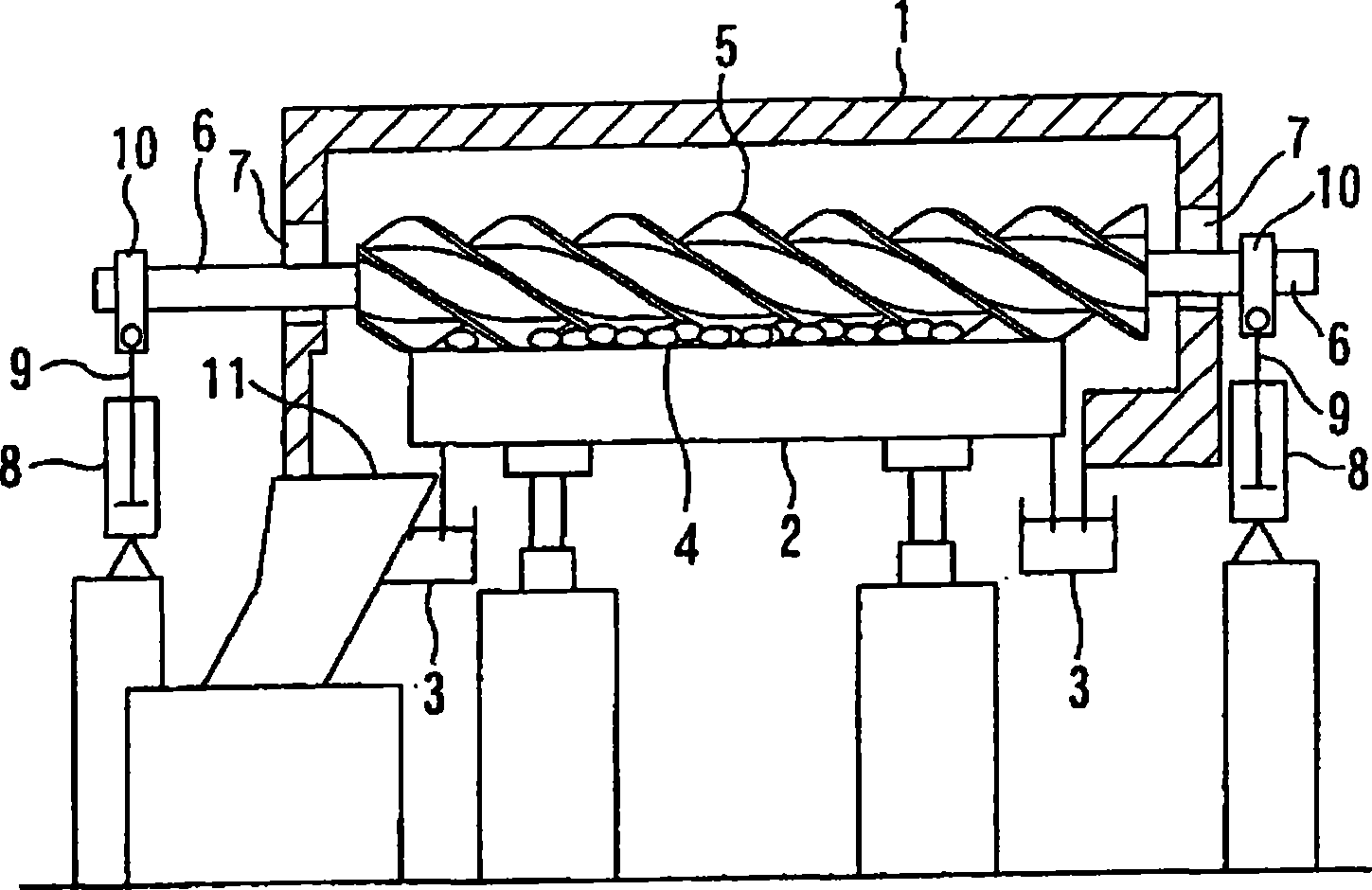

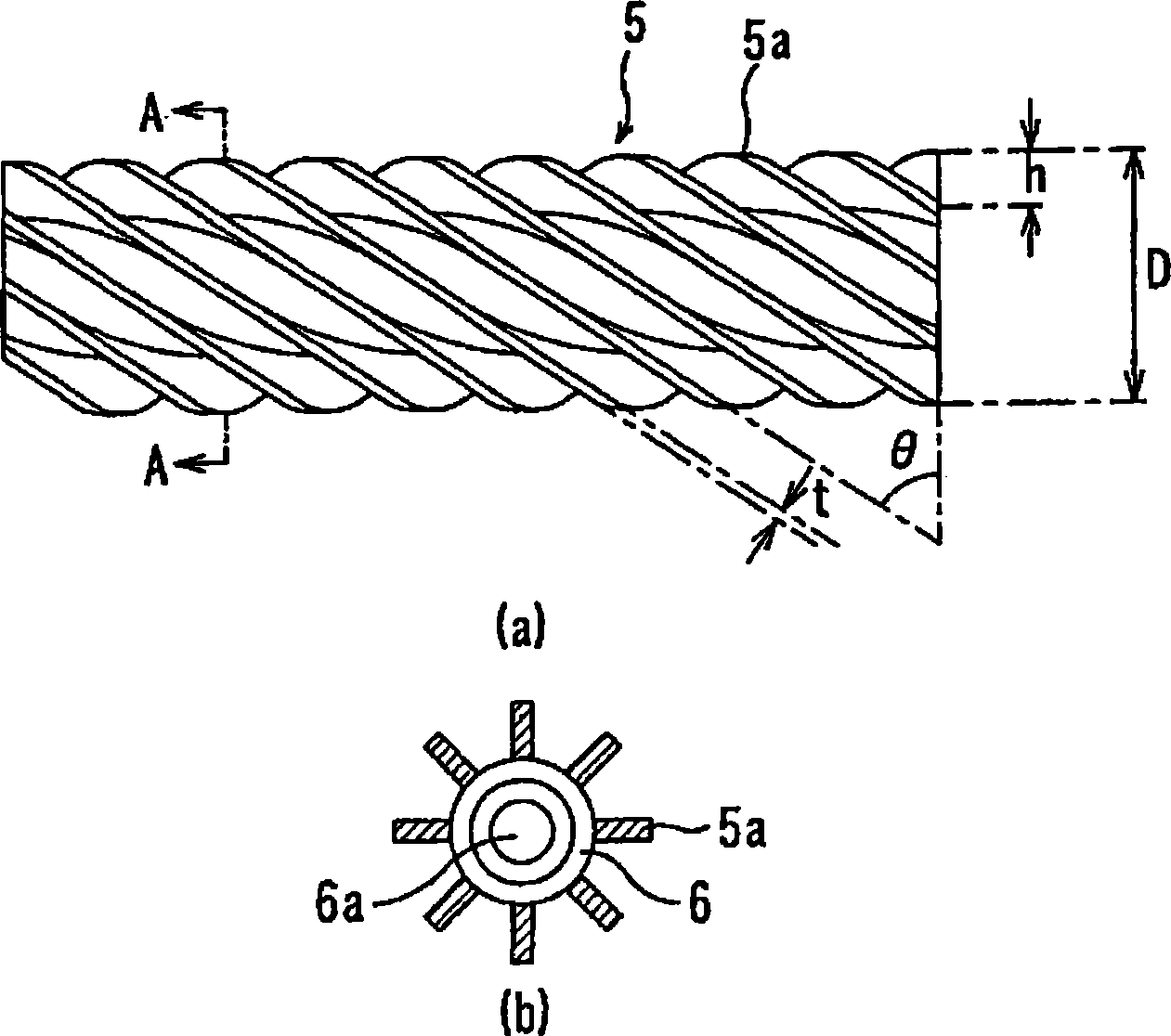

[0025] figure 1 It is a schematic diagram showing an example of a rotary hearth type reduction furnace in which the screw conveyor for discharging reduced iron (hereinafter referred to as "screw conveyor") of the present invention is disposed.

[0026] The rotary furnace bottom 2 is rotatably arranged in the horizontal plane below the furnace body 1 of the rotary hearth type reduction furnace, and the furnace body 1 and the rotary furnace bottom 2 are water-sealed by the ring-shaped water-sealed pipeline 3 so as to maintain the inside of the furnace. atmosphere of.

[0027] The two ends of the rotary shaft 6 of the screw conveyor 5 pass through the long hole 7 of the furnace body 1, and the piston rod 9 of the cylinder 8 arranged outside the furnace supports the screw conveyor 5 so as to be able to move up and down through the bearing 10. 5 is used to discharge the reduced iron 4 obtained after the reduction treatment of the pellets to the outside. The bearing 10 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com