Thin-film transistor, manufacturing method thereof and liquid crystal display panel

A technology for liquid crystal display panels and thin film transistors, which is applied in the manufacture of transistors, semiconductor/solid-state devices, semiconductor devices, etc., can solve the problems of reducing the on/off current ratio, increasing the leakage current value, affecting the display quality of the liquid crystal display panel, etc. The effect of maintaining process quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

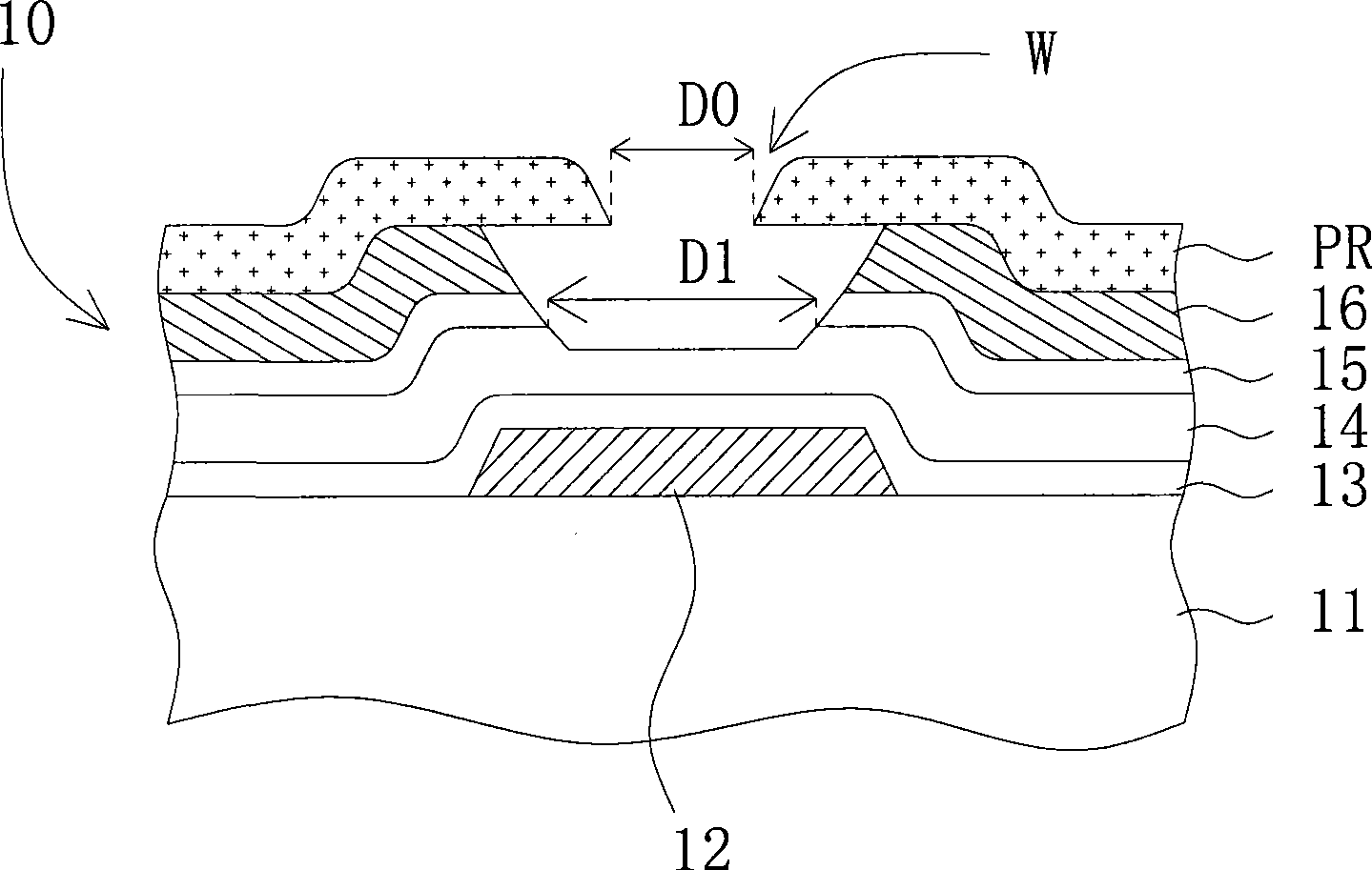

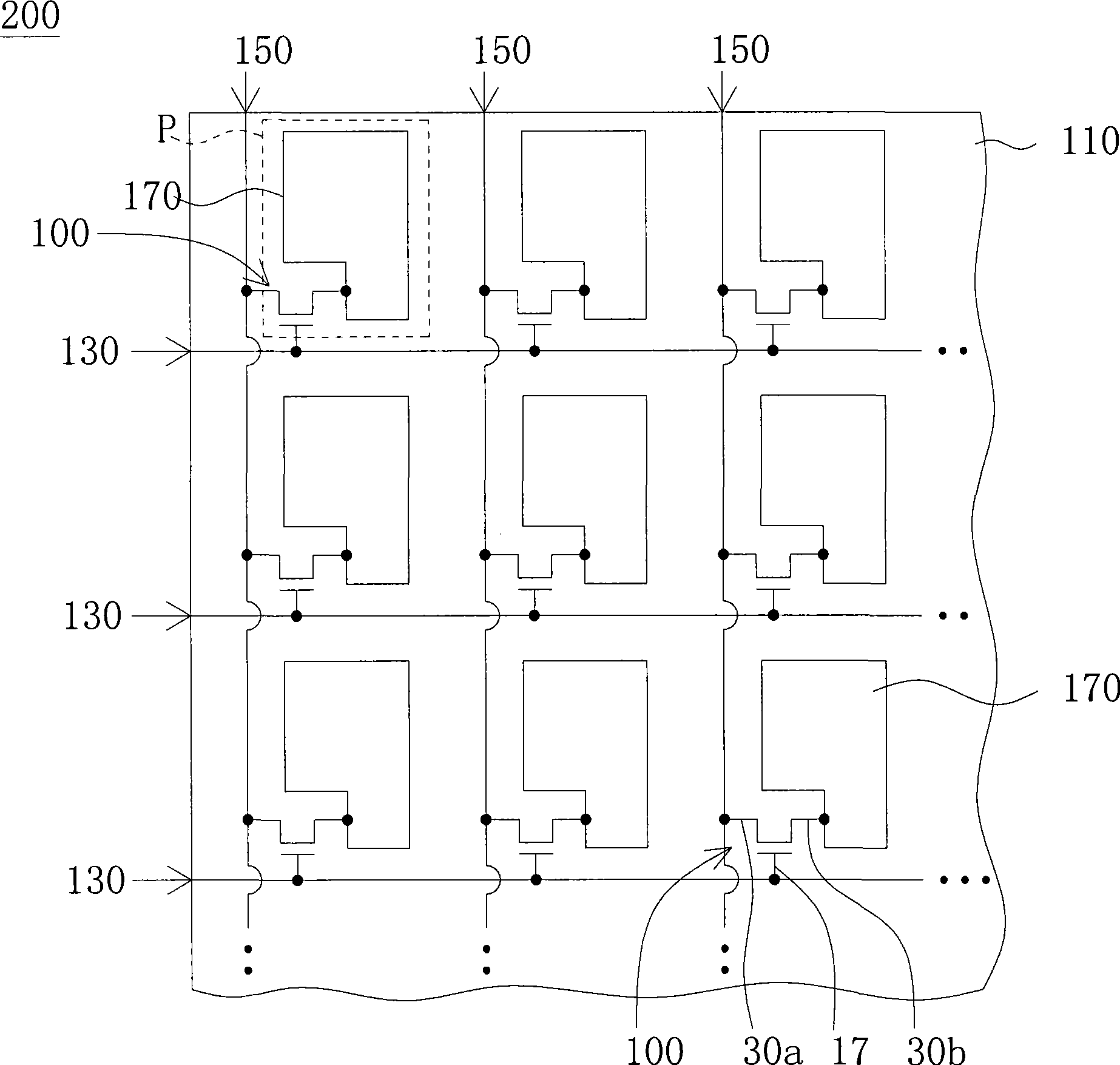

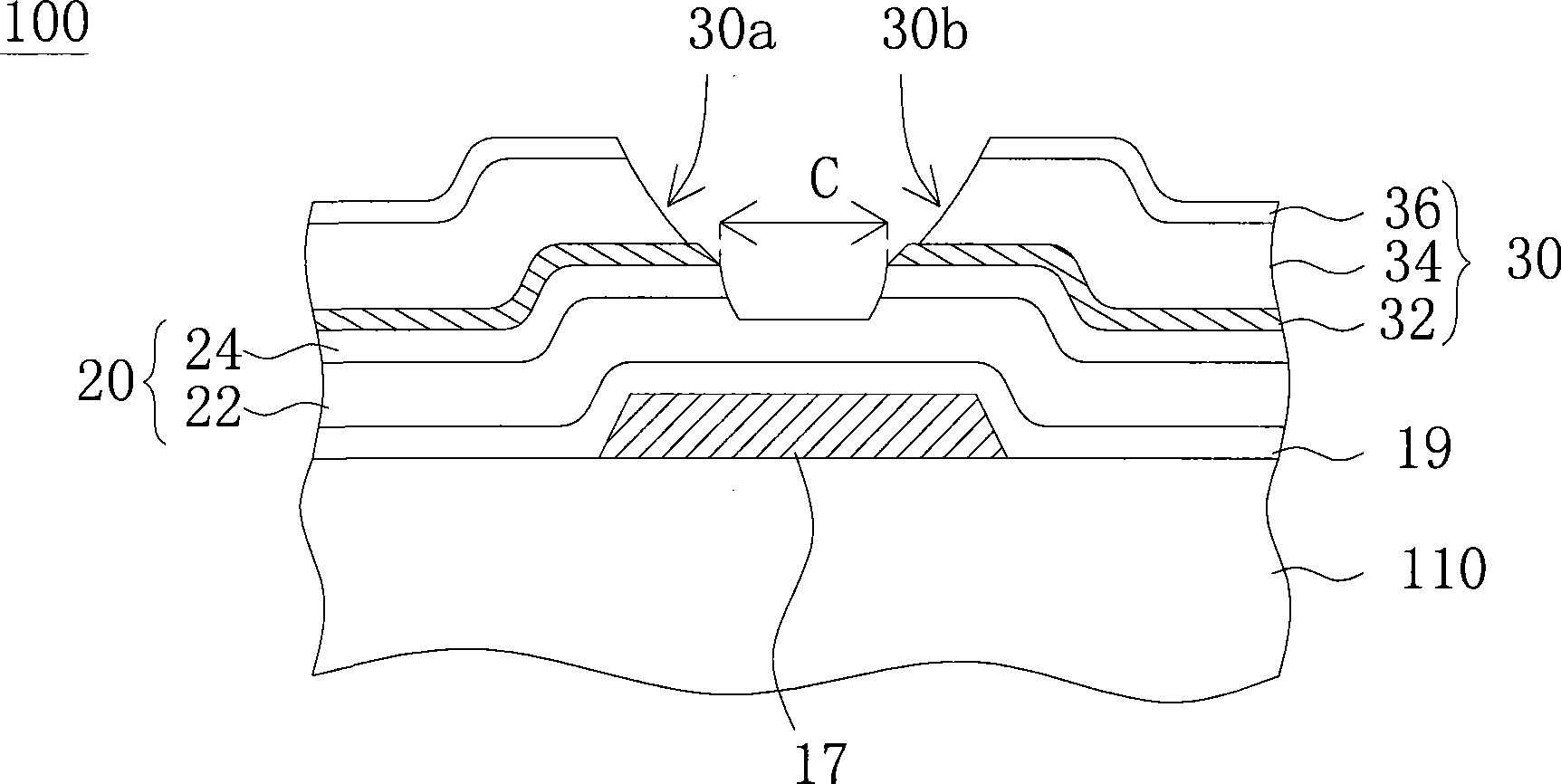

[0051] Please refer to figure 2, which is a partial schematic diagram of a liquid crystal display panel according to a preferred embodiment of the present invention. The liquid crystal display panel 200 includes a substrate 110 , a plurality of scan lines 130 , a plurality of data lines 150 and a plurality of thin film transistors 100 arranged in an array. The scan lines 130 and the data lines 150 are disposed on the substrate 110 , and the data lines 150 are substantially perpendicular to the scan lines 130 . Please also refer to image 3 , which shows figure 2 A cross-sectional view of a thin film transistor. Each TFT 100 includes a gate 17 , a gate insulating layer 19 , a semiconductor layer 20 and a source / drain metallization layer 30 . The gate 17 is disposed on the substrate 110 and is electrically connected to a scan line 130 (such as figure 2 as shown). The gate insulation layer 19 is disposed on the substrate 110 and covers the gate 17 . The semiconductor la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com