Steam generator

A technology for steam generators and transformers, applied in steam generation, steam generation methods, control systems, etc., can solve problems such as waste of electric energy, affecting the service life of electric heating tubes and related components, and achieve reduced use costs, safe use, and Power Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

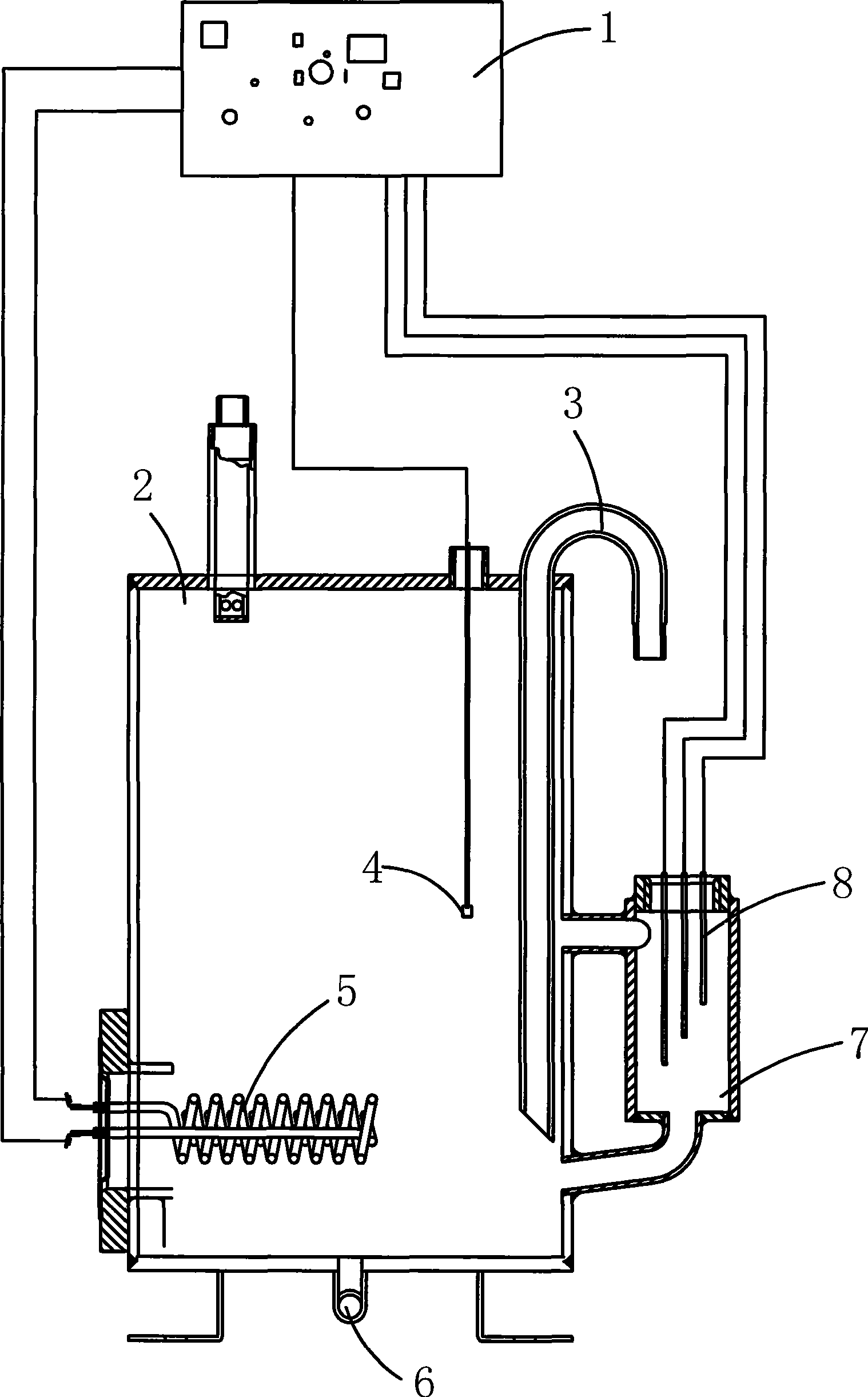

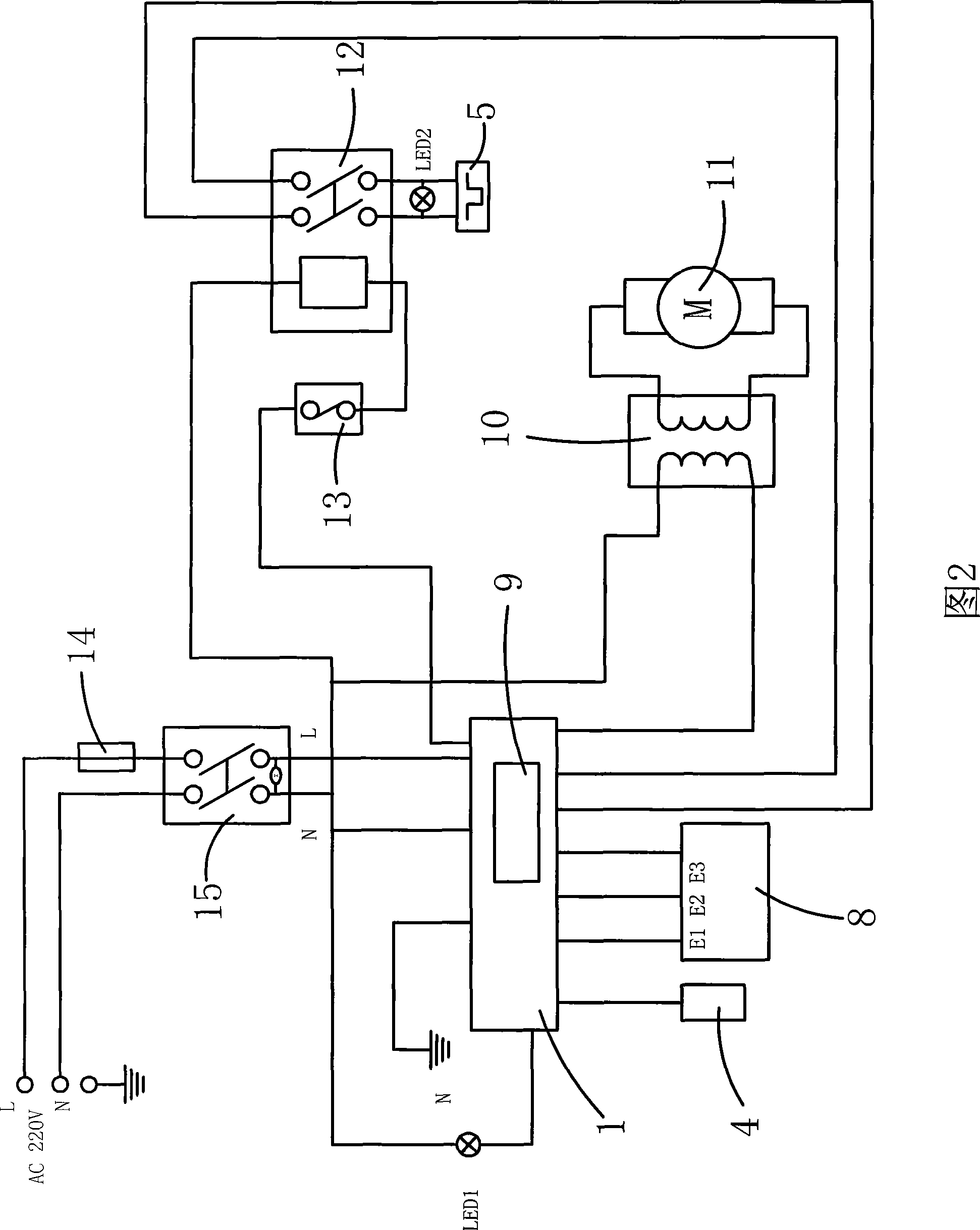

[0012] refer to figure 1 , Fig. 2, a kind of steam generator, comprises steam generator 2 and control panel 1, electric heating tube 5, thermistor 4 electrically connected with control panel 1 are installed in steam generator 2, the bottom of steam generator 2 is arranged There is a sewage pipe 6, the upper part is provided with a water inlet pipe 3, and the bottom of the water inlet pipe 3 extends to the bottom of the steam generator 2. The control panel 1 includes a frequency conversion control module 9. Since the temperature and pressure of the steam in the steam generator 2 are Proportional, it is approximately considered that the information conveyed by the thermistor is the steam pressure information in the steam generator, here, the thermistor 4 can also be replaced by a pressure sensor. The frequency conversion control module 9 outputs the current of the corresponding frequency to the electric heating tube according to the information collected by the thermistor, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com